Pole piece, roll core and battery

A pole piece and winding core technology, applied in the field of batteries, can solve the problems that cannot meet the needs of high current and high voltage occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

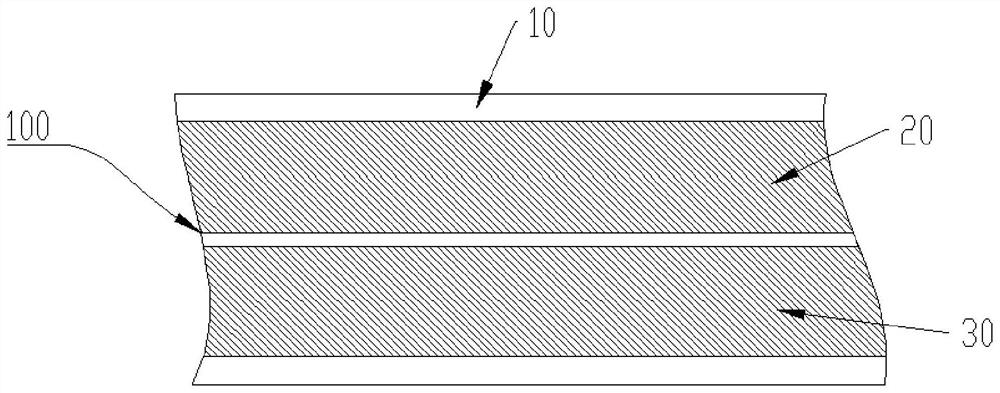

[0057] Such as figure 1 The first specific implementation of the pole piece shown includes: a current collector 10, and two coating areas are arranged at intervals on one side surface of the current collector 10, such as figure 1 As shown, the upper coating area is coated with the positive electrode layer 20 , and the lower coating area is coated with the negative electrode layer 30 .

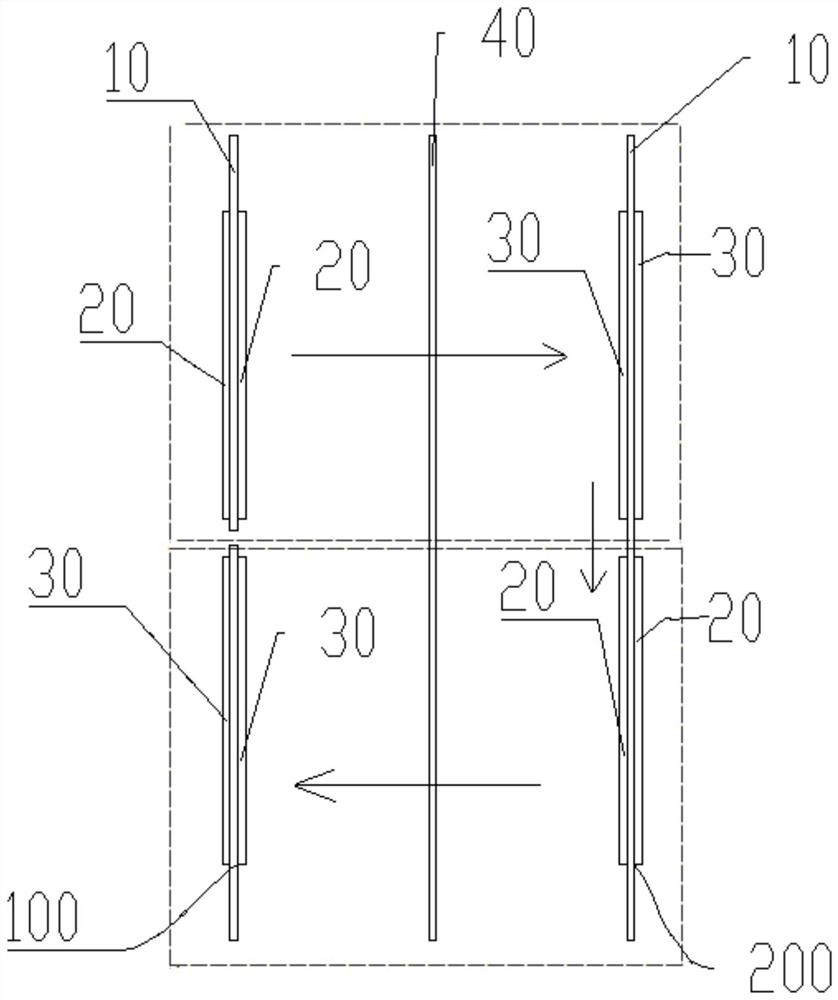

[0058] refer to figure 2 In the pole piece located on the left side of the figure, the positive electrode layer 20 and the negative electrode layer 30 are arranged at intervals from top to bottom on the left side of the current collector 10. Correspondingly, the right side of the current collector 10 is sequentially arranged from top to bottom A positive electrode layer 20 and a negative electrode layer 30 are arranged at intervals.

[0059] In this example, if figure 1 As shown, the current collector 10 between the positive electrode layer 20 and the negative electrode layer 30 is connecte...

Embodiment 2

[0062] Such as figure 1 The second specific embodiment of the pole piece shown includes: a current collector 10, and two coating areas are arranged at intervals on one side surface of the current collector 10, such as figure 1 As shown, the upper coating area is coated with the positive electrode layer 20 , and the lower coating area is coated with the negative electrode layer 30 .

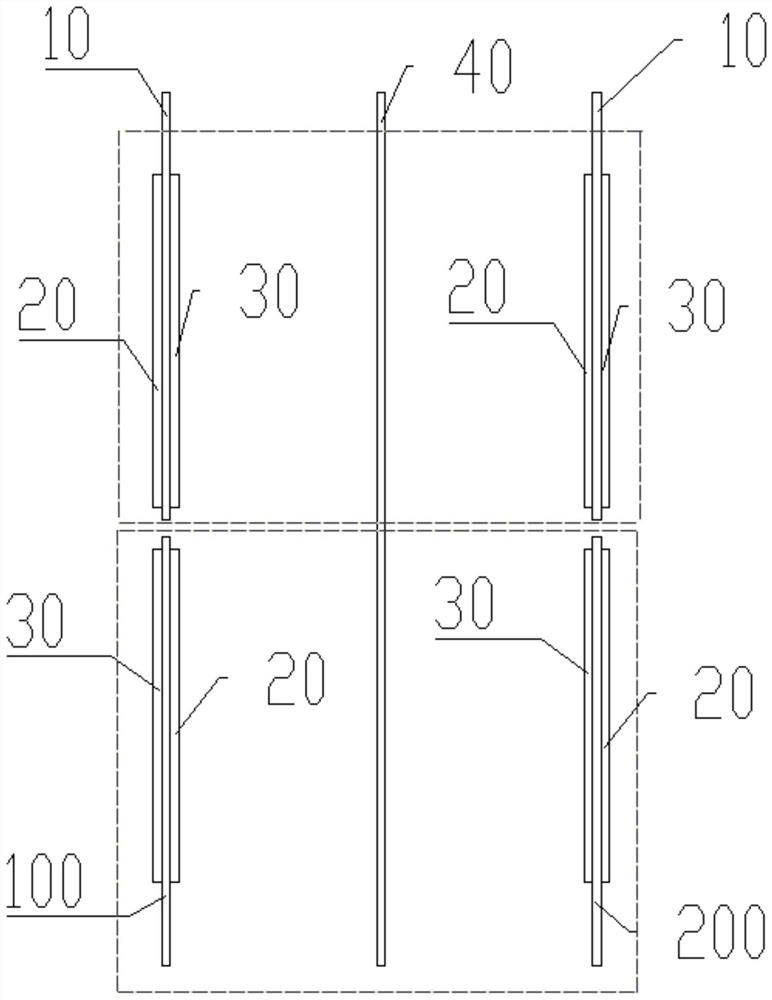

[0063] refer to image 3 In the pole piece located on the left side of the figure, the positive electrode layer 20 and the negative electrode layer 30 are arranged at intervals from top to bottom on the left side of the current collector 10. Correspondingly, the right side of the current collector 10 is sequentially arranged from top to bottom The negative electrode layer 30 and the positive electrode layer 20 are arranged at intervals.

[0064] In this example, if figure 1 As shown, the current collector 10 between the positive electrode layer 20 and the negative electrode layer 30 is connecte...

Embodiment 3

[0067] Such as Figure 4 The third specific embodiment of the pole piece shown includes: a current collector 10, and three coating areas are arranged at intervals on one side surface of the current collector 10, such as Figure 4 As shown, the positive electrode layer 20 , the negative electrode layer 30 and the positive electrode layer 20 are sequentially arranged in the three coating areas from top to bottom.

[0068] refer to Figure 5 In the pole piece located on the left side of the figure, the positive electrode layer 20, the negative electrode layer 30, and the positive electrode layer 20 are arranged at intervals from top to bottom on the left side of the current collector 10. Correspondingly, the right side of the current collector 10 is composed of The anode layer 20 , the anode layer 30 , and the anode layer 20 are sequentially arranged at intervals from top to bottom.

[0069] In this example, if Figure 4 As shown, the current collectors 10 between adjacent pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com