Camera baking real-time detection system and method

A real-time detection and camera technology, applied in the field of camera detection, can solve problems such as insufficient constant temperature time, loss of camera module manufacturers, abnormal baking temperature control, etc., to achieve guaranteed results, prevent human interference baking, and avoid baking abnormal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

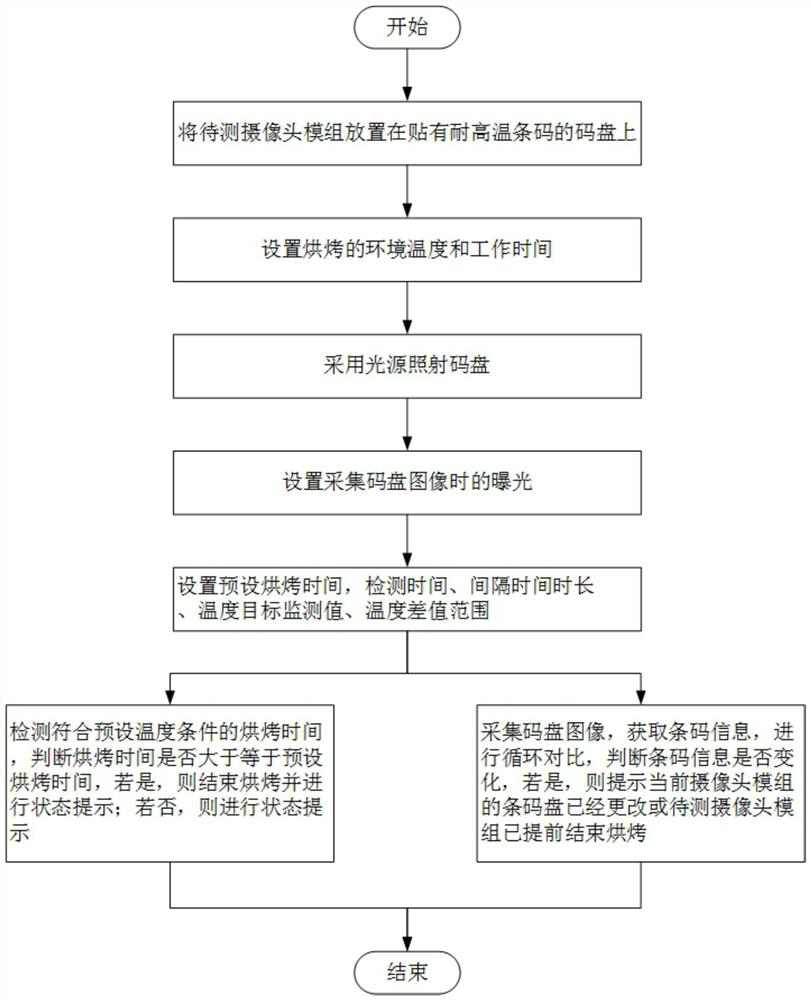

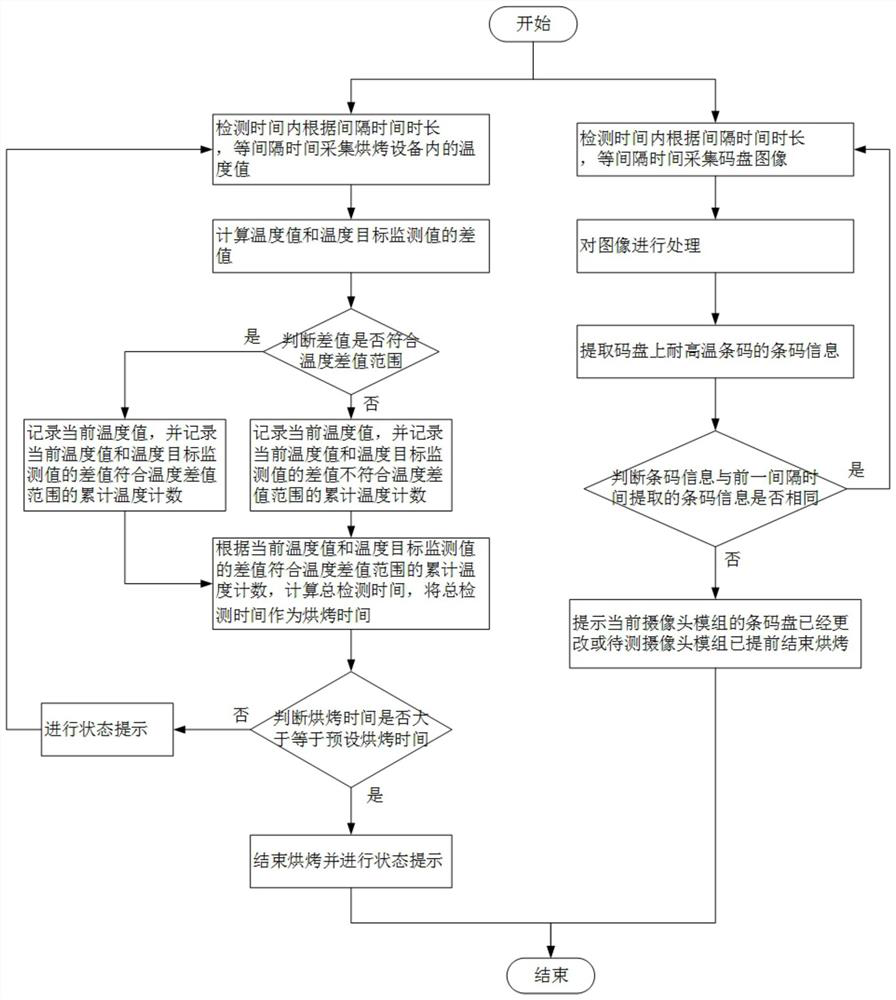

[0084] This embodiment is basically as attached figure 1 Shown: a camera baking real-time detection method, including the following content:

[0085] Place the camera module 3 to be tested on the code disc 2 with a high-temperature-resistant barcode, and bake the camera module 3 to be tested on the code disc 2, specifically: place the camera module 3 to be tested on the code disc 2 with a On the code disc 2 of the high-temperature-resistant barcode, when each group of camera modules 3 to be tested is placed, the high-temperature-resistant barcodes on the code disc 2 are different, ensuring that each group of camera modules 3 to be tested has a unique identification;

[0086] Set the ambient temperature and working time for baking; the ambient temperature is generally set to 20°C-80°C, and the working time is generally set to 4 hours to 24 hours. The specific ambient temperature and working time are based on the baking required by the camera module 3 to be tested Conditions ar...

Embodiment 2

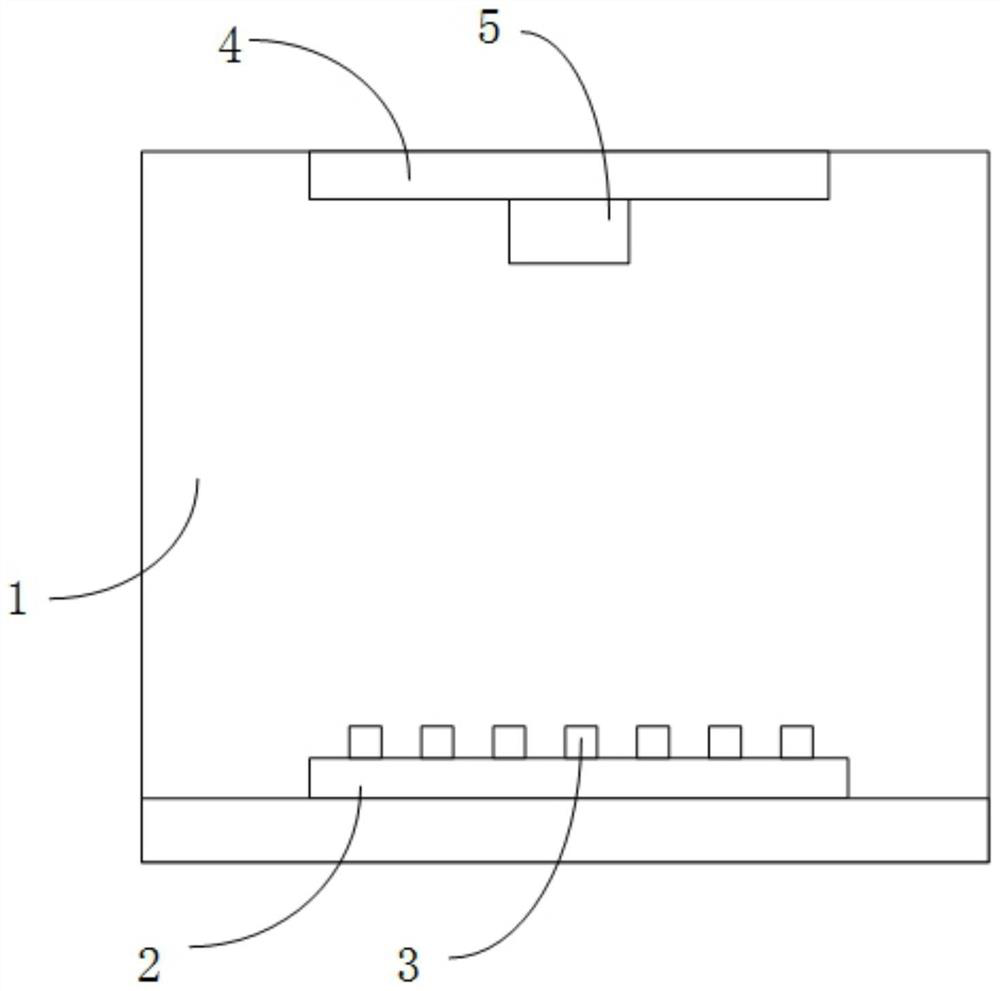

[0114] This implementation provides a camera baking real-time detection system, including: baking equipment 1, detection equipment and light source equipment 5;

[0115] A baking device 1 is used to bake the camera module 3 to be tested placed on the code disc 2 with a high-temperature-resistant barcode; in this embodiment, the baking device 1 is a baking oven;

[0116] The detection device is used to detect the baking time that meets the preset temperature conditions during the baking process, and judge whether the baking time is greater than or equal to the preset baking time. If yes, end the baking and give a status prompt; if not, then Carry out a status prompt; at the same time, collect the code disc 2 image, obtain the barcode information, and perform a cyclic comparison to determine whether the barcode information has changed. If so, it will prompt that the code disc 2 of the camera module to be tested has been changed or the camera module 3 to be tested has End the bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com