A high-density display pcb board repair enclosure fixture and repair method

A PCB board and display technology, applied in printed circuit maintenance/calibration, identification devices, instruments, etc., can solve problems such as damage to lamp tubes and chips, yellowing of LED lamp tubes, heat resistance, poor reflow times, etc., and achieve operation Convenience, avoiding the loss of temperature, and reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution of the present invention will be explained more clearly and completely.

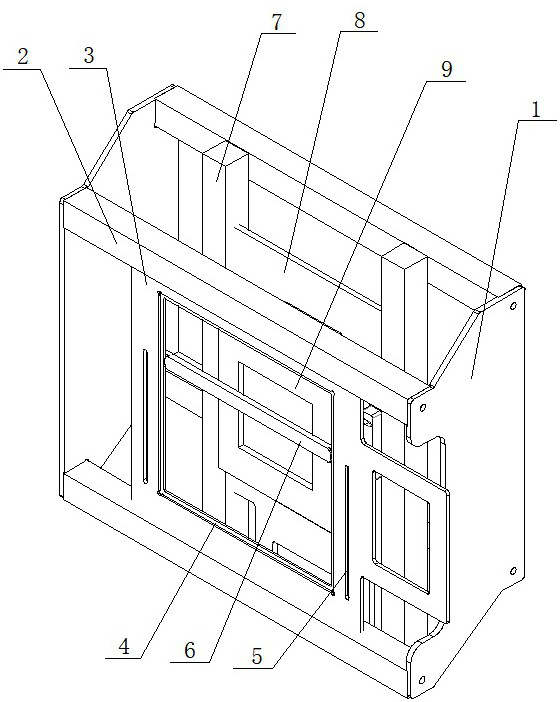

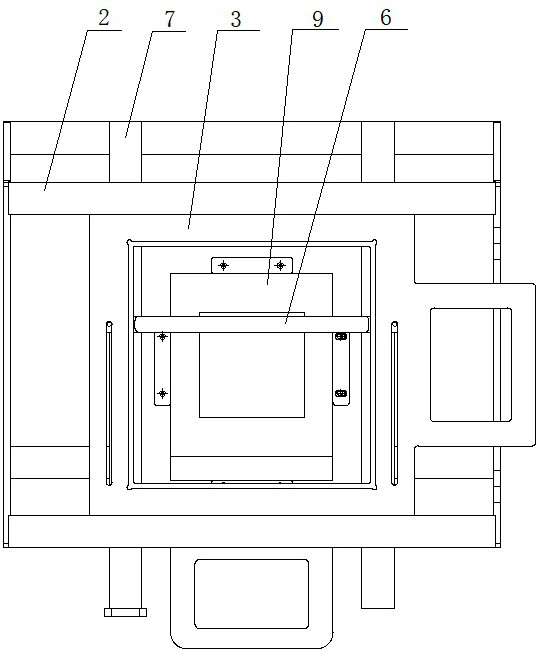

[0027] Such as Figure 1-2 Shown is a high-density display screen PCB board maintenance fence fixture, including the peripheral shield 1 arranged on the heating table, the peripheral shield 1 includes two sides of the shield, between the two sides of the shield through the upper and lower two groups of parallel The set fixed blocks 2 are connected and fixed, and the PCB bracket 3 is slidably connected between the upper set of fixed blocks 2, and a set of support blocks 7 are erected vertically on the lower set of fixed blocks 2, and the inner enclosure 9 is supported by the enclosure frame 8. Block 7 sliding connection. Thereby, the sliding adjustment of the PCB bracket 3 and the inner enclosure 9 in two directions is realized, thereby realizing fixed-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com