Automatic plate feeding device for flexible circuit board electroplating line

A technology of flexible circuit boards and electroplating lines, applied in the direction of electrical components, electrical components, printed circuits, etc., to achieve the effects of high practicability, convenient operation and use, and fast loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

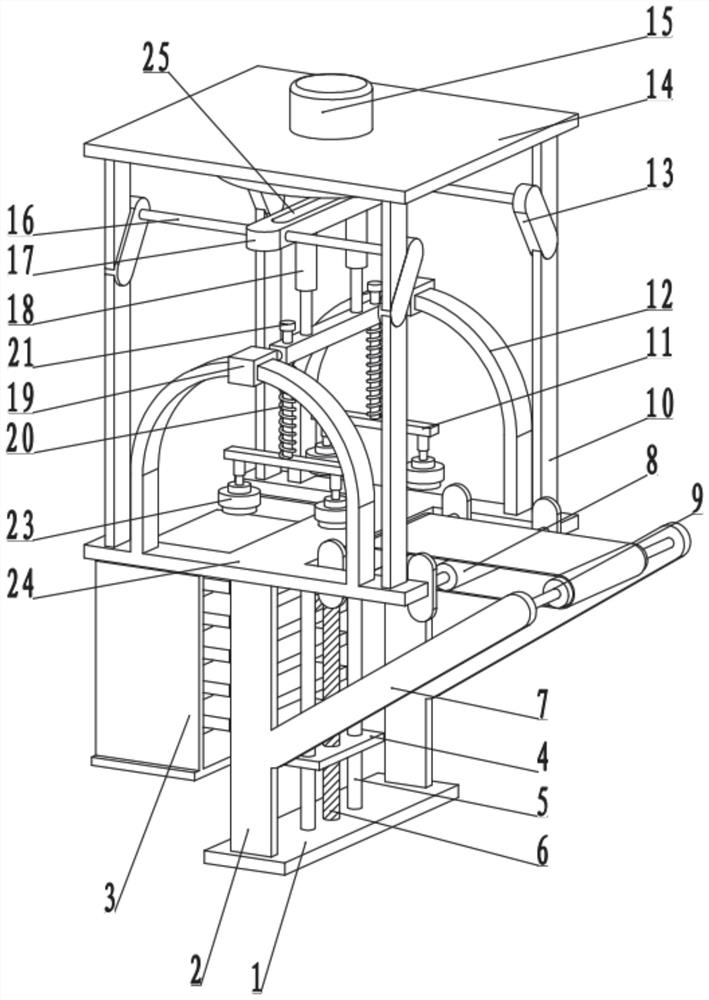

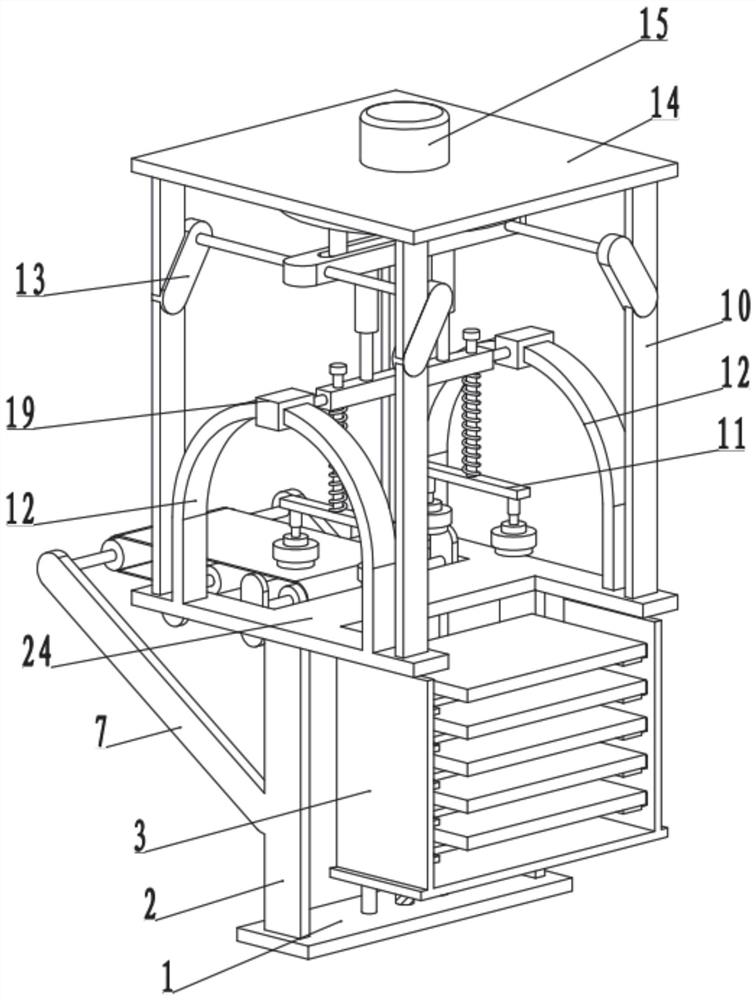

[0028] see Figure 1-5 , an automatic board loading device for a flexible circuit board electroplating line, including a base plate 1, and also includes:

[0029] The support plate 2 fixedly arranged on both sides of the bottom plate 1, the top of the support plate 2 is fixedly connected to the bearing plate 24, and the top plate 14 is arranged above the bearing plate 24;

[0030] The upper plate mechanism arranged between the top plate 14 and the carrying plate 24 includes slide rails 12 fixedly arranged on both sides of the carrying plate 24, the slide rails 12 are U-shaped structures, and sliding blocks 19 are sleeved on the slide rails 12, Carrying beams 28 are arranged between the sliding blocks 19, and the two sides of the carrying beams 28 are rotationally connected with the sliding blocks 19. The two sides of the carrying beams 28 slide through and set the piston rods 21, and the bottom of the piston rods 21 is fixedly provided with a mounting rod 11. An elastic membe...

Embodiment 2

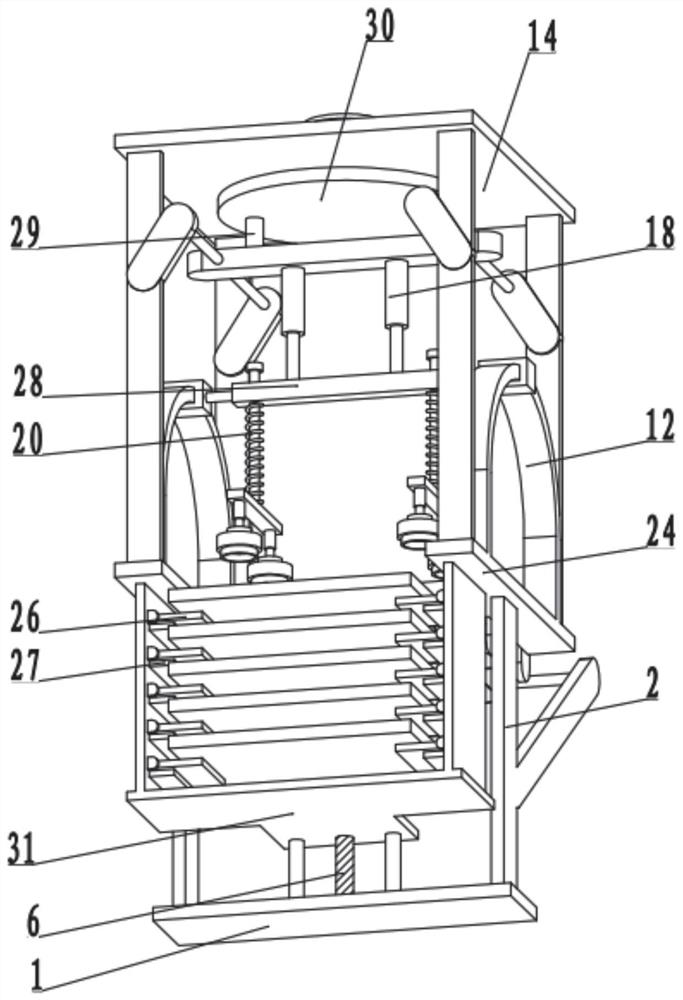

[0034] see Figure 1-5 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the drive assembly includes a drive disc 30 rotatably arranged at the bottom of the top plate 14, one side of the bottom of the drive disc 30 is fixedly connected to the fixed shaft 29, and the bottom side of the fixed shaft 29 is A movable beam 17 is provided, and a chute 25 is provided on the movable beam 17 , and the fixed shaft 29 extends into the chute 25 and is in sliding contact with the movable beam 17 .

[0035] The top plate 14 on both sides of the movable beam 17 and the bearing plate 24 are fixedly connected to the support rod 10, one side of the support rod 10 is fixedly connected to the mounting block 13, and the mounting blocks 13 are fixedly connected to the bearing column 16, and the bearing column 16 slides through the On the movable beam 17 , a telescopic tube 18 is fixedly arranged between the movable beam 17 and the bearing beam 28 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com