Wafer fixing ring and CMP equipment with same

A wafer fixing and grinding ring technology, which is used in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as affecting the quality of wafer grinding, and achieve the effect of avoiding the impact and improving the overall quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

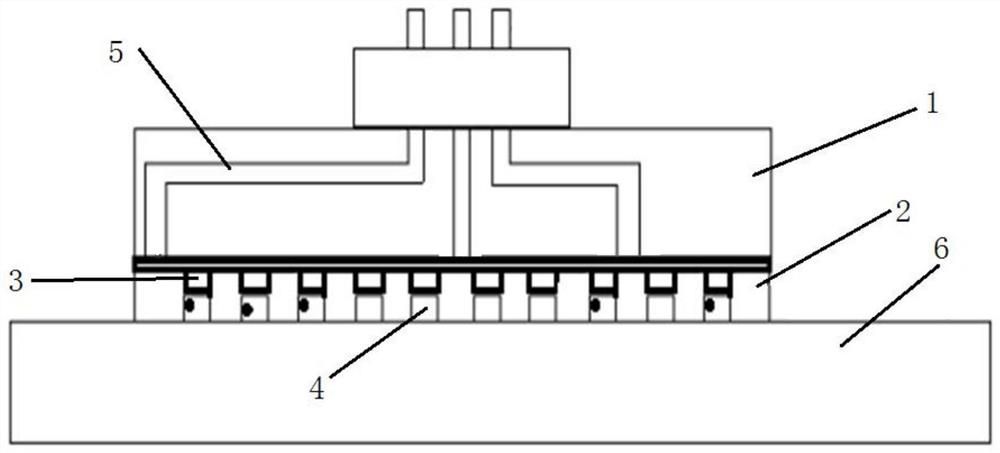

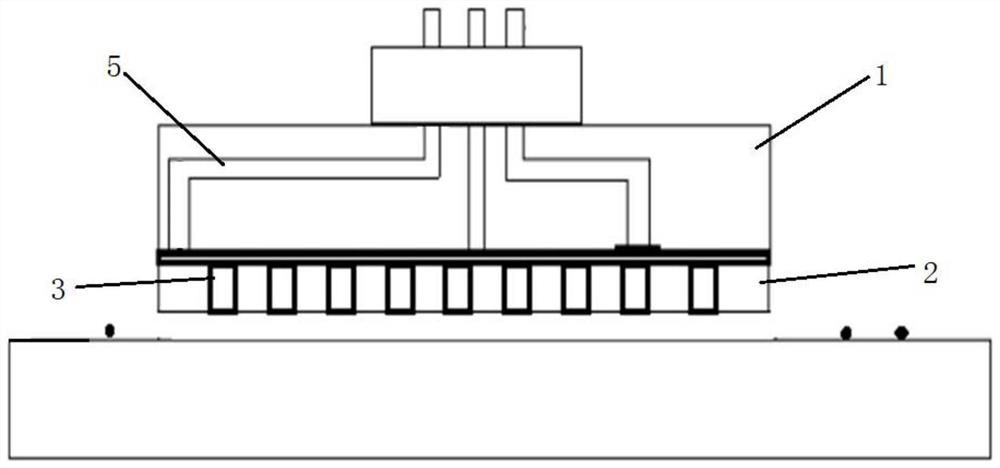

[0036] like Figure 1 to Figure 4 Shown is a wafer fixing ring provided by this embodiment, wherein figure 1 and figure 2 Solid black dots in are residues. It includes: a support ring 1 as a support, a grinding ring 2 and a telescopic assembly 3 installed between the support ring 1 and the grinding ring 2 .

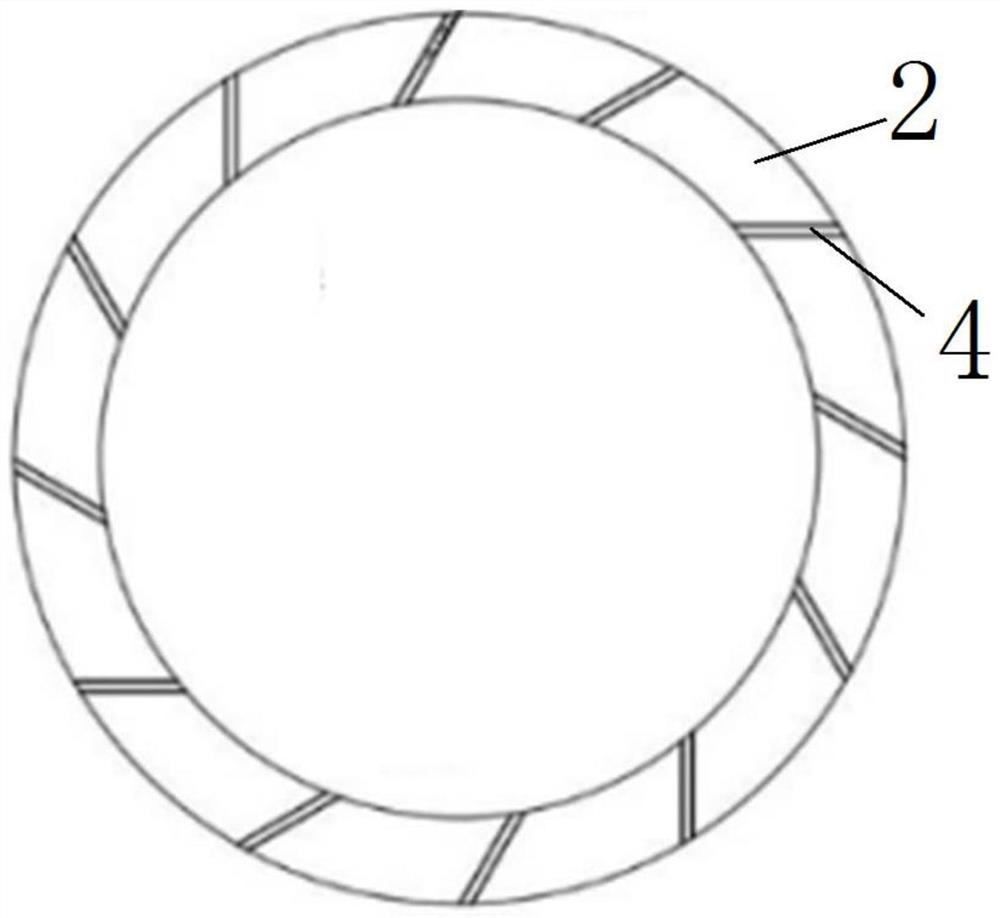

[0037] The support ring 1 and the grinding ring 2 are arranged coaxially, and the inner circle of the support ring 1 is the same diameter as the inner circle of the grinding ring 2, and the outer circle of the support ring 1 is the same diameter as the outer circle of the grinding ring 2. The grinding ring 2 is installed on one side of the support ring 1 in parallel, and a plurality of grooves 4 are arranged at intervals on the grinding ring 2 , the grooves 4 extend toward the support ring 1 and the grooves 4 pass through the grinding ring 2 .

[0038] The telescopic assembly 3 is installed between the support member and the grinding ring 2 , and the telescopic assemb...

Embodiment 2

[0047] This embodiment provides a CMP device with the wafer fixing ring described in Embodiment 1. When cleaning the wafer fixing ring, control the expansion of the telescopic assembly in the groove to a clean state, so that the telescopic assembly fills the groove and pushes out the residue in the groove. With high-pressure water spray cleaning, it can be quickly and easily removed The removal of the grinding residue in the groove can prevent the grinding residue in the groove from affecting the subsequent grinding and polishing wafers, and can greatly improve the overall quality of all wafers in the entire batch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com