Printing head spiral water-cooling heat dissipation device of 3D printer

A 3D printer, water cooling technology, applied in coating devices, manufacturing auxiliary devices, additive processing, etc., can solve problems such as affecting the stability of 3D printers, increase heat absorption efficiency, prolong heat absorption time, increase The effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

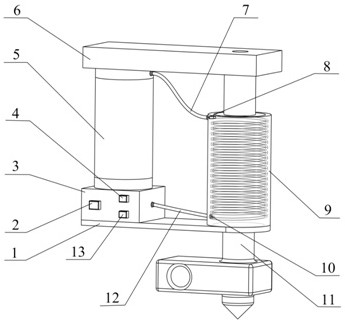

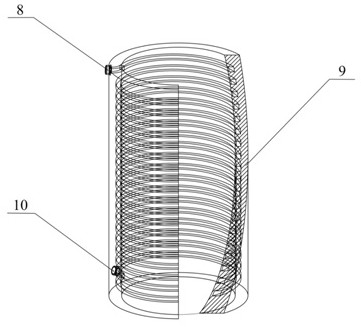

[0010] like figure 1 , The present invention provides a 3D printer nozzle spiral water cooling device, its structure includes an upper fixing table 6, a lower fixing table 1, a water cooling sleeve 9, a water inlet pipe 12, a water outlet pipe 7, an adapter 8, a water tank 5 and a water pump 3. The water-cooled sleeve sleeve 9 is connected to the print head 11. The water-cooled sleeve 9 is fixed up and down by the upper fixed table 6 and the lower fixed table 1. The water-cooled sleeve 9 is provided with a square spiral channel inside, and the water-cooled sleeve is provided with There are water inlet and water outlet, the lower part is the water inlet, the upper part is the water outlet, the connecting water pipe and the water cooling sleeve 9 are connected through the button-type adapter 8, and the heat of the printing nozzle 11 is transferred through the water in the water cooling sleeve 9. In this way, the temperature of the printing nozzle 11 is lowered.

[0011] Next to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com