Automatic assembling and paving machine for composite floors

A composite flooring and paving machine technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of unfavorable production line work efficiency, affecting production capacity, artificial embryo formation, etc., achieve simple structure, improve production efficiency, The effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

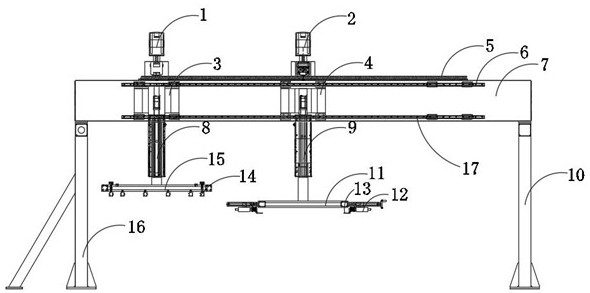

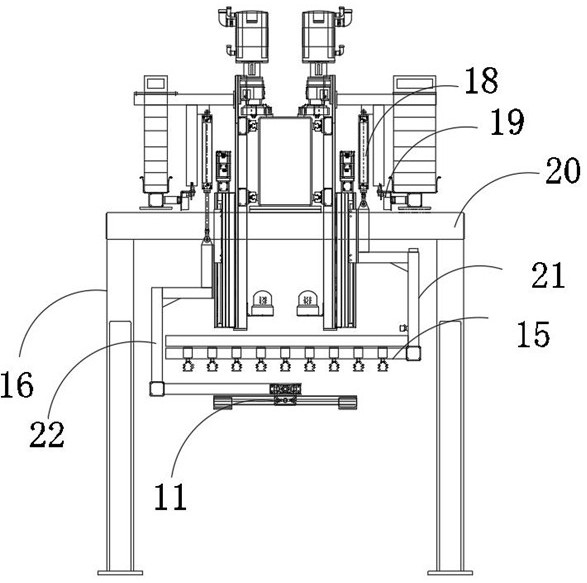

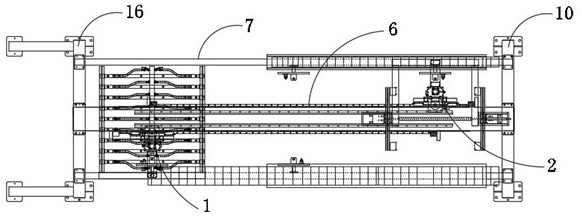

[0029] like Figure 1-3 , Shown in 5, a kind of composite floor is used automatic laying and paving machine, comprises No. 1 reducer 1, No. 2 reducer 2, No. 1 frame 10, No. 2 frame 16, No. The frame 16 is fixedly connected with a crossbeam 7, and the crossbeam 7 is welded on the top of the middle position of the No. The board conveying vehicle 4, the panel conveying vehicle 3 are connected with the No. 1 reducer 1, and the core plate conveying vehicle 4 is connected with the No. 2 reducer 2.

[0030] Panel transport vehicle 3 comprises No. 1 elevator 8, suction cup frame 15, No. 1 connection assembly 21, movable adjustment mechanism 26 and the suction cup 14 on the suction cup frame 15, the lifting movement end of No. 1 elevator 8 is movably connected with suction cup frame 15, and the core board Transport vehicle 4 comprises No. 2 elevator 9, No. 2 connecting assembly 22, loading frame 11 and the loading clip 13 and cylinder 12 installed on the loading frame 11, and the lift...

Embodiment 2

[0034] like figure 1 , 2, Shown in 4, 5, a kind of composite floor is used automatic laying and laying machine, comprises No. The No. 2 frame 16 is fixedly connected with a crossbeam 7, and the crossbeam 7 is welded on the top of the middle position of the No. 1 frame 10 and the No. 2 frame 16. The left and right sides of the crossbeam 7 are equipped with movable panel transport vehicles 3 It is connected with the core plate conveying vehicle 4, the panel conveying vehicle 3 is connected with the No. 1 reducer 1, and the core plate conveying vehicle 4 is connected with the No. 2 reducer 2.

[0035] Panel transport vehicle 3 comprises No. 1 elevator 8, suction cup frame 15, No. 1 connection assembly 21, movable adjustment mechanism 26 and the suction cup 14 on the suction cup frame 15, the lifting movement end of No. 1 elevator 8 is movably connected with suction cup frame 15, and the core board Transport vehicle 4 comprises No. 2 elevator 9, No. 2 connecting assembly 22, loa...

Embodiment 3

[0040] like figure 1 , 2 , Shown in 5-7, a kind of composite floor is used automatic laying and laying machine, comprises No. The No. 2 frame 16 is fixedly connected with a crossbeam 7, and the crossbeam 7 is welded on the top of the middle position of the No. 1 frame 10 and the No. 2 frame 16. The left and right sides of the crossbeam 7 are equipped with movable panel transport vehicles 3 It is connected with the core plate conveying vehicle 4, the panel conveying vehicle 3 is connected with the No. 1 reducer 1, and the core plate conveying vehicle 4 is connected with the No. 2 reducer 2.

[0041] Panel transport vehicle 3 comprises No. 1 elevator 8, suction cup frame 15, No. 1 connection assembly 21, movable adjustment mechanism 26 and the suction cup 14 on the suction cup frame 15, the lifting movement end of No. 1 elevator 8 is movably connected with suction cup frame 15, and the core board Transport vehicle 4 comprises No. 2 elevator 9, No. 2 connecting assembly 22, loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com