Gas path system for rotor system of micro gas turbine and micro gas turbine

A technology of micro gas turbine and gas circuit system, which is applied in the direction of gas turbine device, engine lubrication, machine/engine, etc. It can solve problems affecting stability and gas film shape fluctuations, so as to prolong service life, switch smoothly, and ensure stable operation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

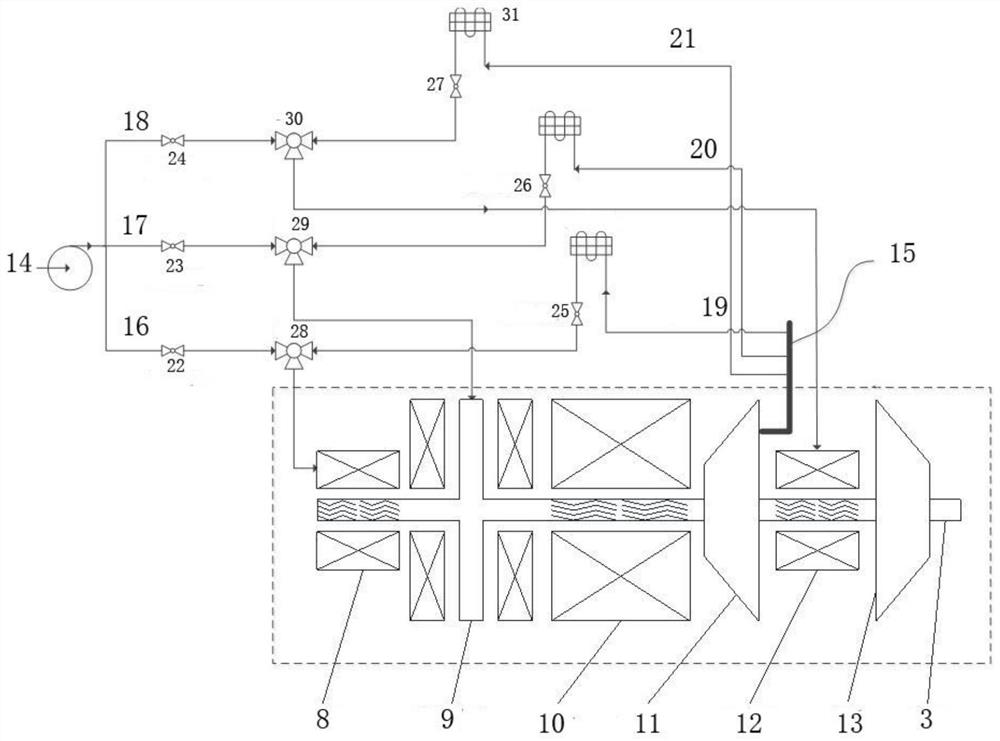

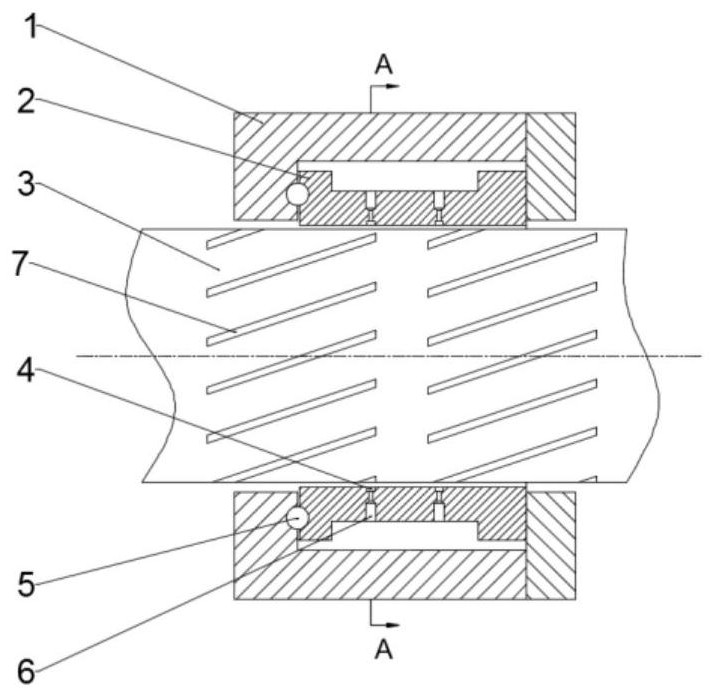

[0033] Embodiment 1 Gas path system for micro gas turbine rotor system and micro gas turbine

[0034] A gas path system for a micro gas turbine rotor system, the rotor system includes a rotating shaft 3, on which a first radial bearing 8, a first thrust bearing 9, a motor 10, a compressor 11, and a second radial bearing are sequentially arranged 12 and turbo 13, such as figure 1 As shown, the first radial bearing 8, the first thrust bearing 9, and the second radial bearing 12 are all air bearings (dynamic pressure bearings or dynamic and static pressure hybrid bearings); the compressor 11 may include a compressor impeller and a diffuser.

[0035]The air circuit system includes an air pump 14, an air source air circuit, a self-static pressure supplementary air circuit and a tee, wherein the input end of the air pump 14 communicates with the air source, and the output end of the air pump 14 communicates with the input end of the air source air circuit. Connected, the output end...

Embodiment 2

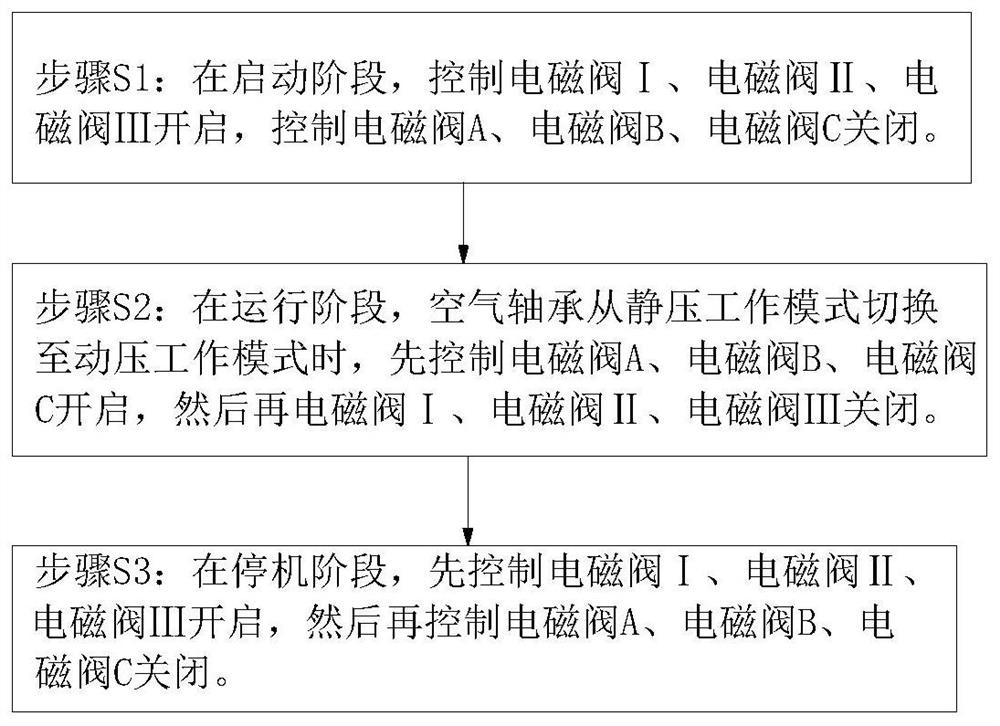

[0050] Embodiment 2 Carry out the control method of self-static pressure air supplement

[0051] The control method for self-static pressure supplementary air by using the air circuit system of Embodiment 1 includes the steps: when the air bearing in the rotor system is switched from the static pressure working mode to the dynamic pressure working mode, firstly control the opening of the self-static pressure supplementary air circuit , and then control the gas source and gas path to close. In this way, when the air bearing in the rotor system is switched from the static pressure working mode to the dynamic pressure working mode, the high-pressure gas provided by the compressor is introduced as the supplementary air source, realizing self-static pressure supplementation at the moment of performing the dynamic and static pressure state switching of the air bearing The effect of the air film balances the shape fluctuation of the air film of the air bearing caused by the stop of t...

Embodiment 3

[0061] Embodiment 3 Gas path system for micro gas turbine rotor system and micro gas turbine

[0062] The structure is the same as in Embodiment 1, the difference is that two radial bearings and two thrust bearings are arranged on the rotating shaft, both of which are air bearings (dynamic pressure bearings or dynamic and static pressure mixed air bearings), and correspondingly, there are four tees , the air source air path and the self-static pressure air supply air path each include 4 branch air paths, the two branch air paths supplying air to the same air bearing meet through the tee, and then supply air to the corresponding air bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com