Automatic compensation drum brake

An automatic compensation and drum brake technology, applied in the field of mechanical drum brakes, can solve the problems of reduced brake sensitivity, looseness, and large safety hazards, and achieve the effects of increased shoe life, less production difficulty, and sensitive brakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

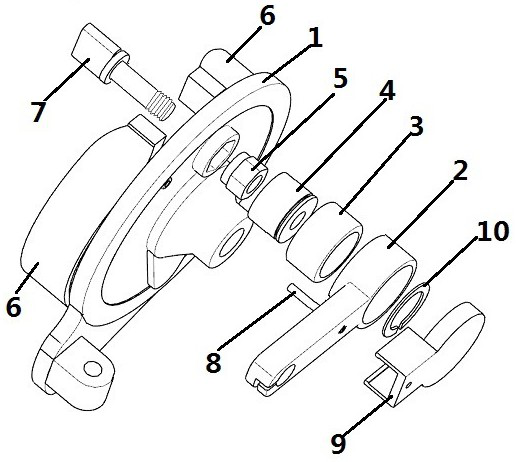

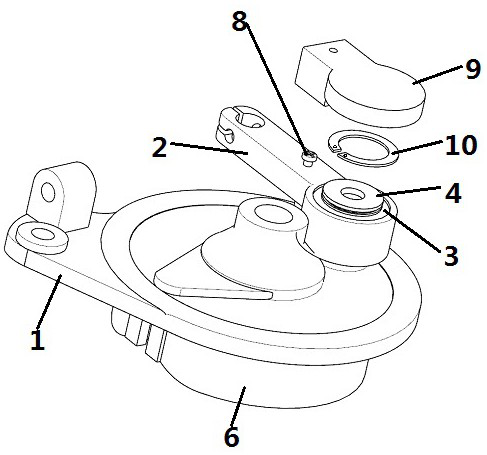

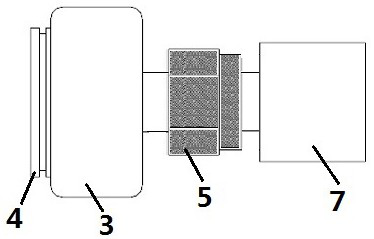

[0018] see Figure 1-5 As shown, an automatic compensation drum brake includes a drum cover 1, a rocker arm 2, a camshaft 7, a set of one-way bearings 3, two sets of one-way bearings 5, a brake shoe block 6 and a return spring 61 thereof. The brake shoes 6 are connected and placed in the drum cover 1, and one set of one-way bearings 3 and two sets of one-way bearings 5 are arranged on the camshaft 7, and the camshaft 7 is connected to the rocker arm 2 through one set of one-way bearings 3, The two sets of one-way bearings 5 are used to connect the drum cover 1 and abut against the brake shoes 6. The two sets of one-way bearings rotate in the same direction. In the figure, one set of one-way bearings 3 is a one-way bearing with a circular outer ring. The second group 5 of the bearing is an outer ring pentagonal one-way bearing.

[0019] The first one-way bearing is provided with an inner liner 4, and the camshaft 7 is tightly connected to the inner liner 4. The embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com