Bar slowly-cooled material lifting appliance with self-closing release function

A bar, slow cooling technology, applied in the direction of load hanging components, transportation and packaging, to achieve the effect of good adaptability, convenient operation and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

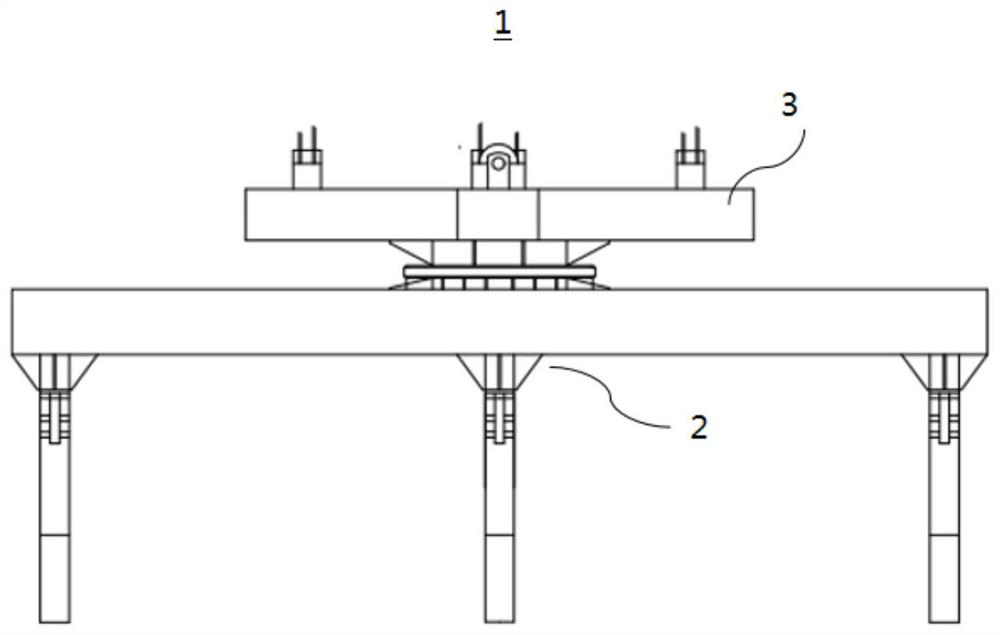

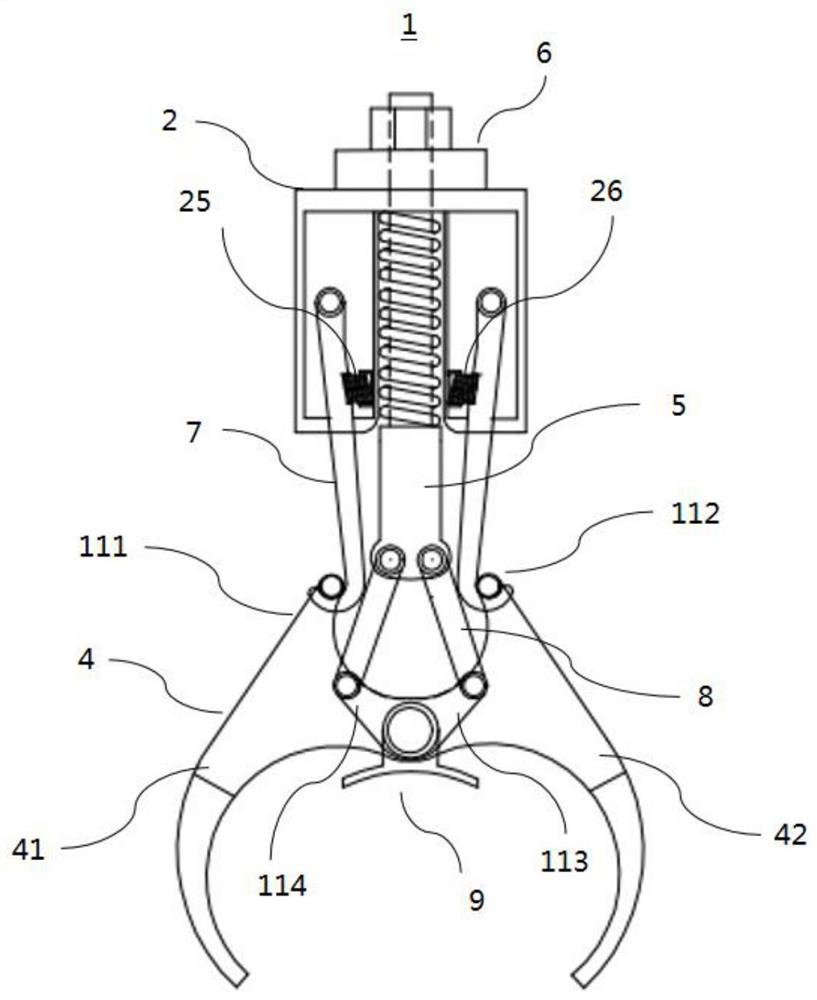

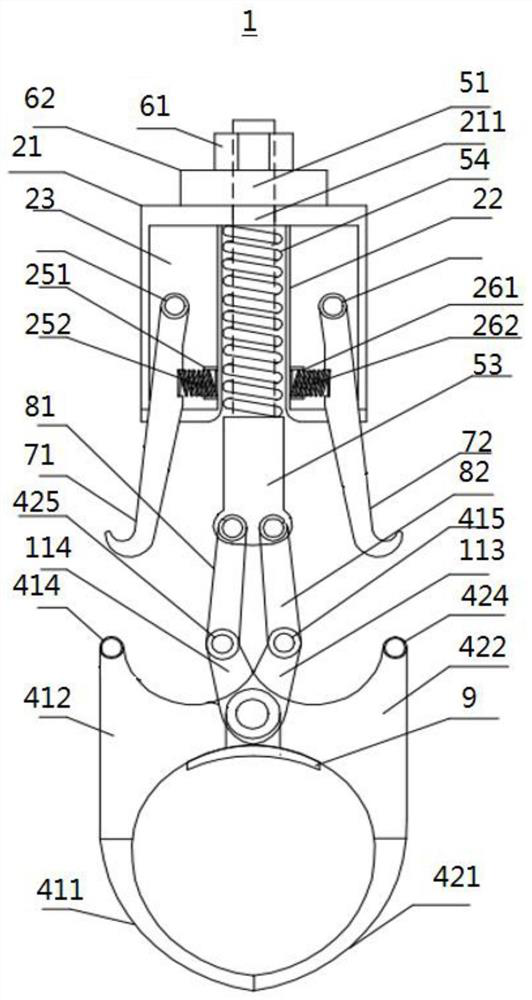

[0053] see Figure 1-Figure 2 , the embodiment of the present application provides a slow-cooled bar hanger 1 with self-closing and releasing function, including a beam part 2, a lifting and rotating part 3, a claw part 4, a boom part 5, a first connecting part 6, a second The second connection part 7, the third connection part 8 and the clamp baffle part 9;

[0054] see figure 1 The lifting rotating part 3 is installed above the crossbeam part 2, and the lifting rotating part 3 can be a kind of lifting mode connected by the pulley of the cross-shaped hanging beam on the disc, the wire rope and the driving mechanism on the driving mechanism. Specifically, the lifting and rotating component 3 is installed on the square steel beam 21 and can drive the square steel beam 21 up and down.

[0055] see Figure 2-Figure 4 , The beam component 2 includes a square steel beam 21 , a cylinder 22 , a first connecting rib 23 , a second connecting rib 24 , a first spring sleeve 25 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com