Combined cutter device of hydraulic cementing insulation clamping plate dismantling device

An insulating splint and combined technology, which is applied in the field of parts and components, can solve the problems of easy damage, high cost, and large loss, and achieve the effects of not easy to damage, good stress conditions, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the above technical solutions of the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples.

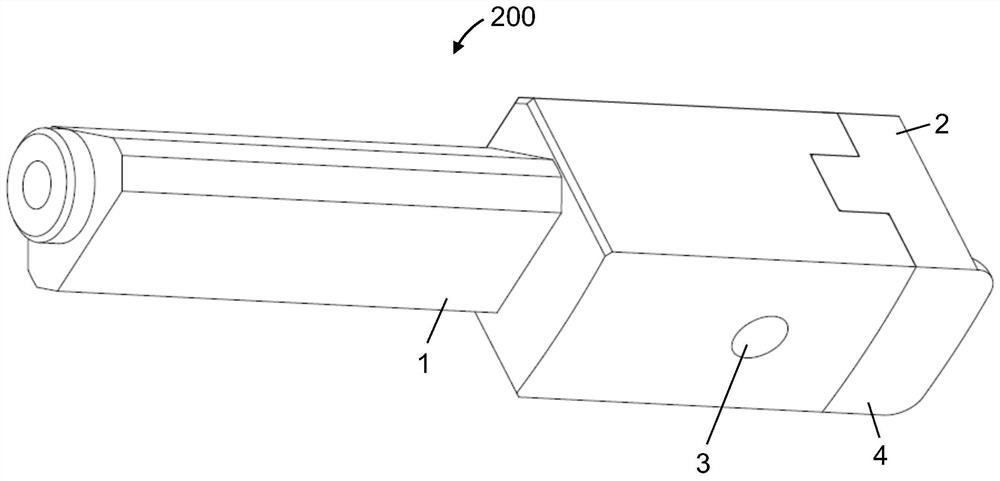

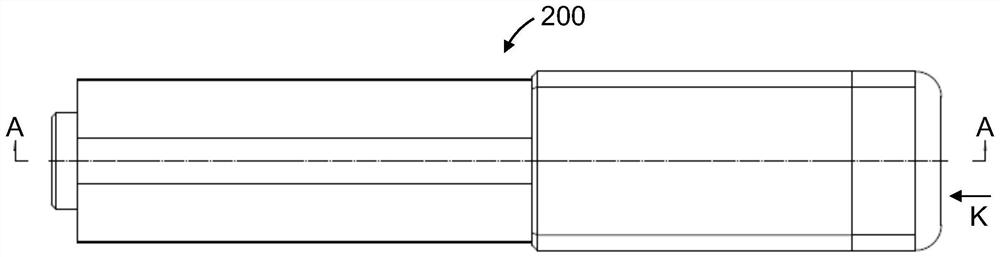

[0027] Combine figure 1 As shown, a combined cutter device of a hydraulic adhesive insulating splint removal device according to the present invention is provided on a main frame 100 of the hydraulic glue splint disassembly device, including two symmetrical setting of the cutter 200, can Better finished the work of the removal of the rubber splint.

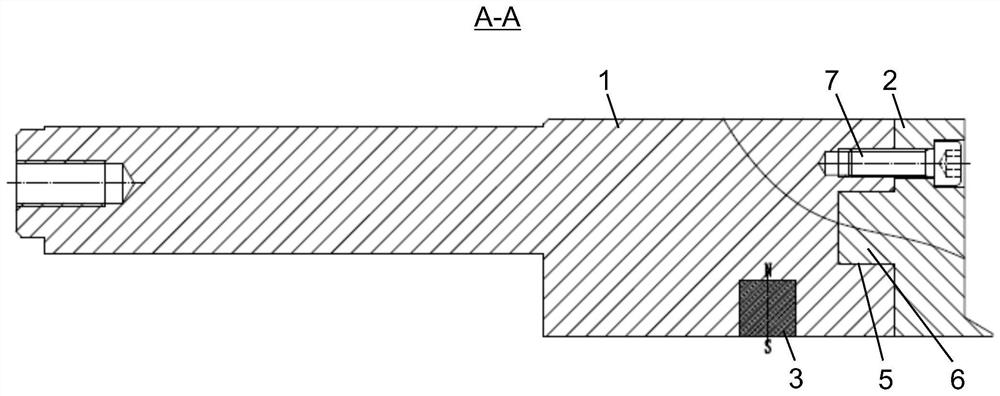

[0028] Each of the fixed cutters 200 includes a knife handle 1, a cutter head 2, and a magnet 3.

[0029] The rear end of the tool holder 1 is connected to the main frame 100 through the screw, and the front end is connected to the cutter head 2.

[0030] The working surface 4 of the cutter head 3 is disposed as a circular arc shape, and the arc radius is in line with the arc radius of the track.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com