Bent pipe welding device

A welding device and pipe bending technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low efficiency, low efficiency, and waste of time for manual welding, and save time for fixing pipe materials and alignment , The structural design is ingenious and compact, and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

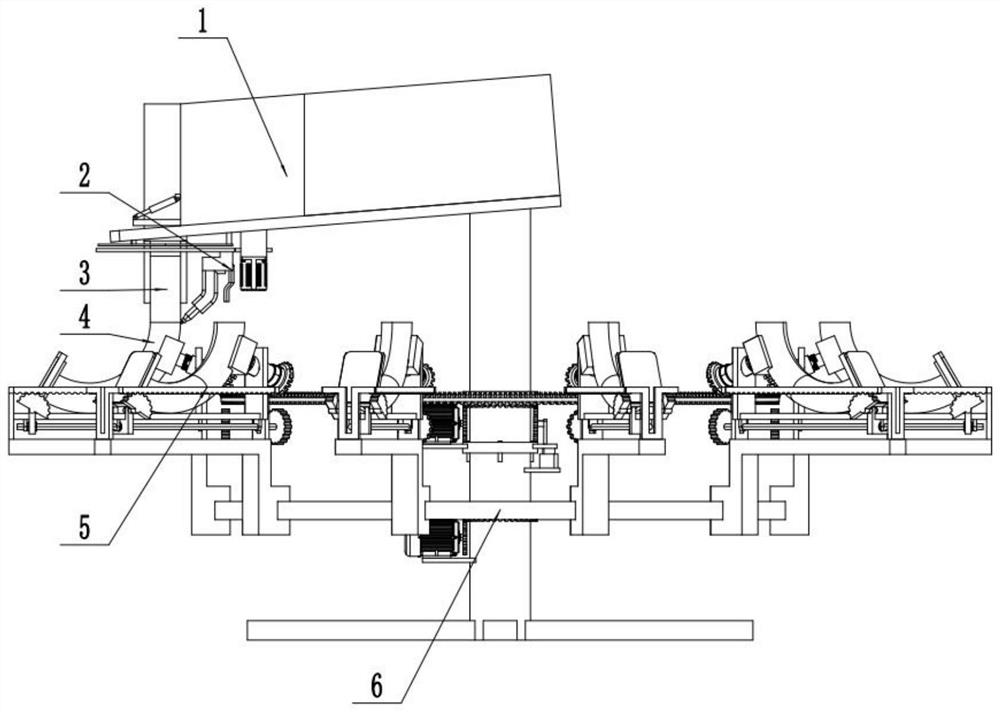

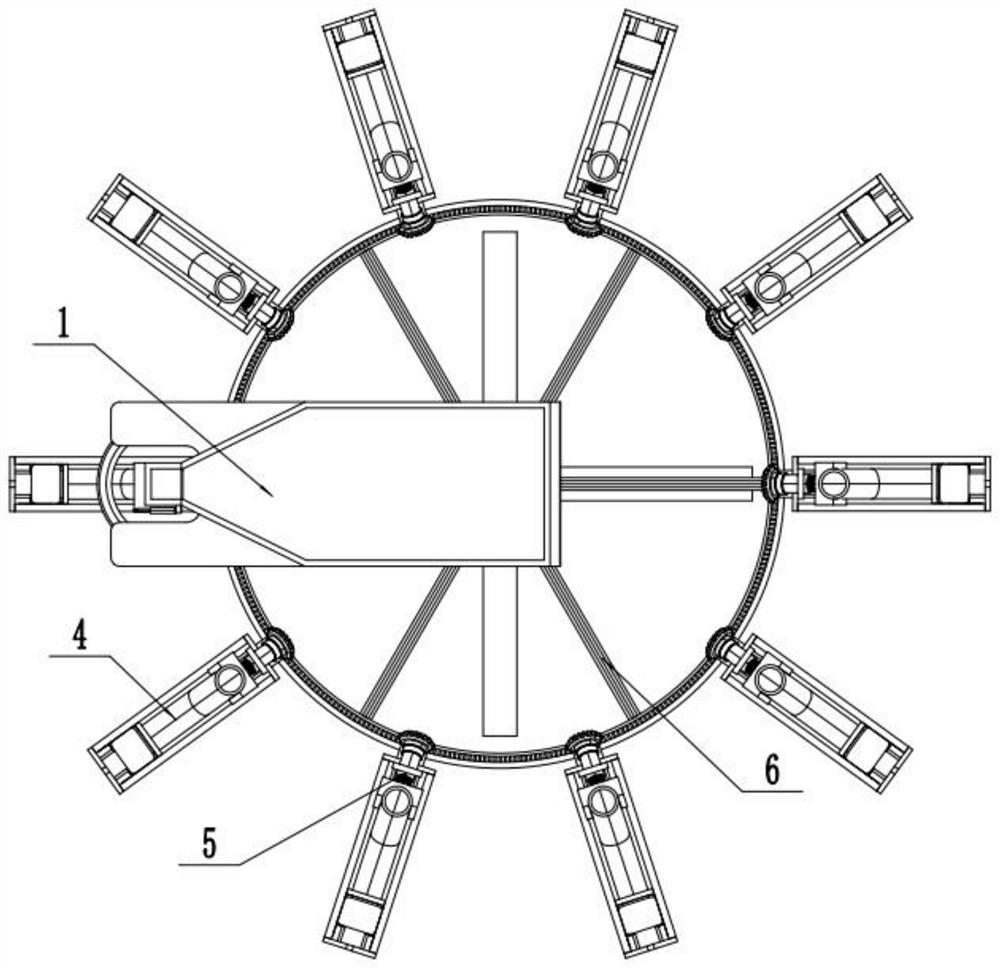

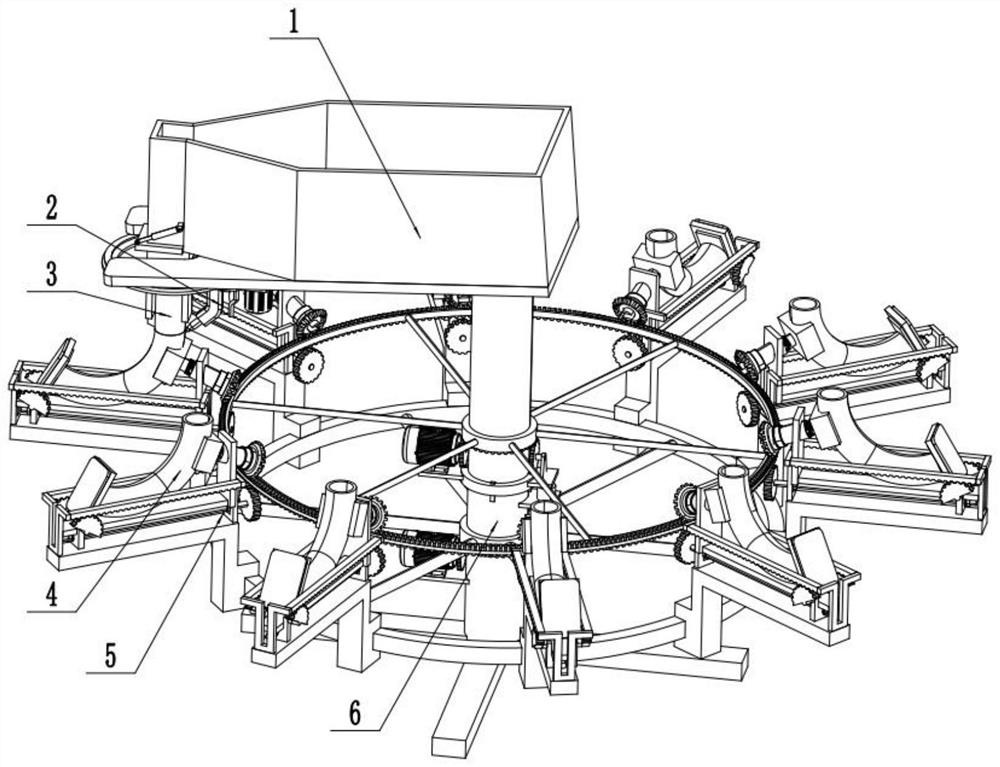

[0027] Example: such as Figure 1-Figure 3 As shown, an elbow welding device includes a stocking assembly 1, a welding assembly 2, a clamping assembly 5 and a bracket assembly 6, the stocking assembly 1 is fixedly installed above the bracket assembly 6, and the stocking assembly 1 is used for storing straight There are a plurality of clamping assemblies 5 uniformly distributed on the circumference of the tube 3 and the bracket assembly 6, and the plurality of clamping assemblies 5 rotate under the drive of the bracket assembly 6, and the clamping assemblies 5 are used to clamp the elbow 4, and the storage assembly 1 A welding assembly 2 for welding straight pipes 3 and bent pipes 4 is provided below.

[0028] like Figure 3-Figure 6As shown, the bracket assembly 6 includes a first support 601, a bracket ring 602, a first connecting rod 603, a first swivel 604, a driving gear ring 605, a second connecting rod 606, a second swivel 607, and a first motor 608 , the second gear 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com