Small box girder inner mold and construction method for pouring small box girder

A construction method and technology of small box girders, which are applied in the direction of manufacturing tools, ceramic forming mandrels, ceramic forming machines, etc., can solve the problems of poor concrete pouring of the bottom slab, and achieve the effect of improving pouring quality, pouring compactness, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

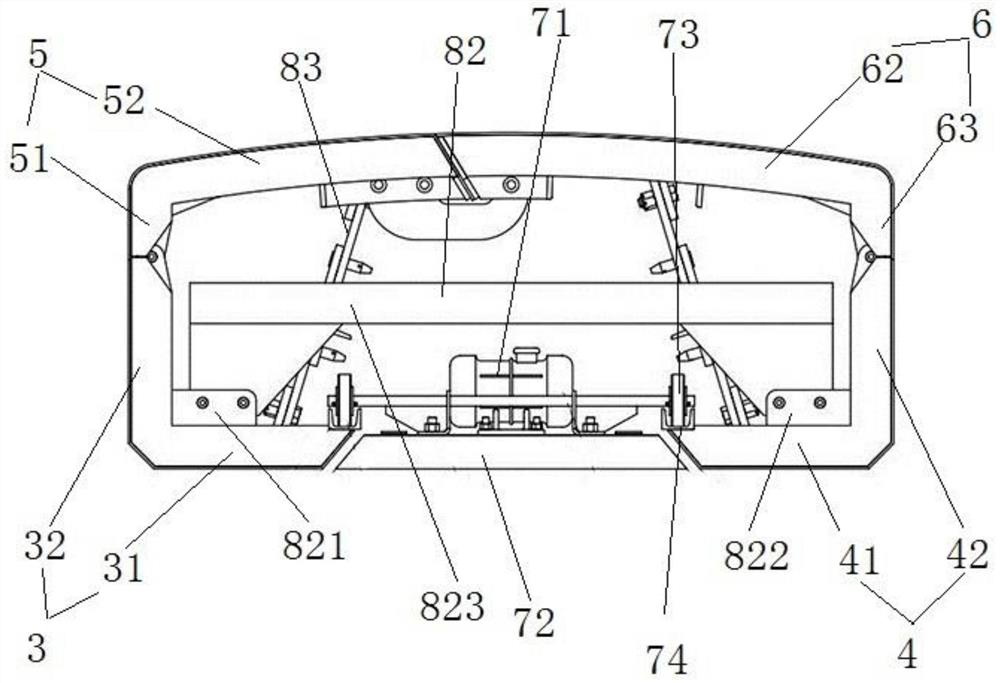

[0050] refer to Figure 1a with figure 2 As shown, this embodiment discloses an inner mold for a small box girder, including an inner mold and a flat vibrator 7 . The top of the inner mold is provided with feeding windows 1 arranged at intervals along its length direction; the bottom of the inner mold is provided with a long opening 2 extending along its length direction. The concrete needed for pouring the bottom plate of the small box girder can be replenished in the long opening 2 through the feeding window 1 . The flat vibrator 7 is installed on the bottom of the inner mold so that it can move along the extending direction of the long opening 2, and the poured floor concrete is vibrated by the flat vibrator 7 while moving in the long opening 2.

[0051] In this embodiment, the concrete required for pouring the bottom slab is replenished through the filling window 1, and the poured bottom slab concrete is vibrated by the plate vibrator 7 at the same time, which reduces th...

Embodiment 2

[0071] refer to Figure 7 As shown, this embodiment provides a construction method for pouring a small box girder using the small box girder inner mold provided in Example 1, and its specific process includes:

[0072] The first step is to install the beam-making base, and install the bottom form on the beam-making base.

[0073] Specifically, it includes installing the bottom form to the beam-making pedestal, cleaning the sundries on the bottom form panel, checking the flatness and curvature of the bottom form, and evenly applying a release agent on the bottom form panel.

[0074] The second step is to assemble the inner mold and bind the steel bars, and hoist the inner mold with the steel bars bound to the beam-making pedestal.

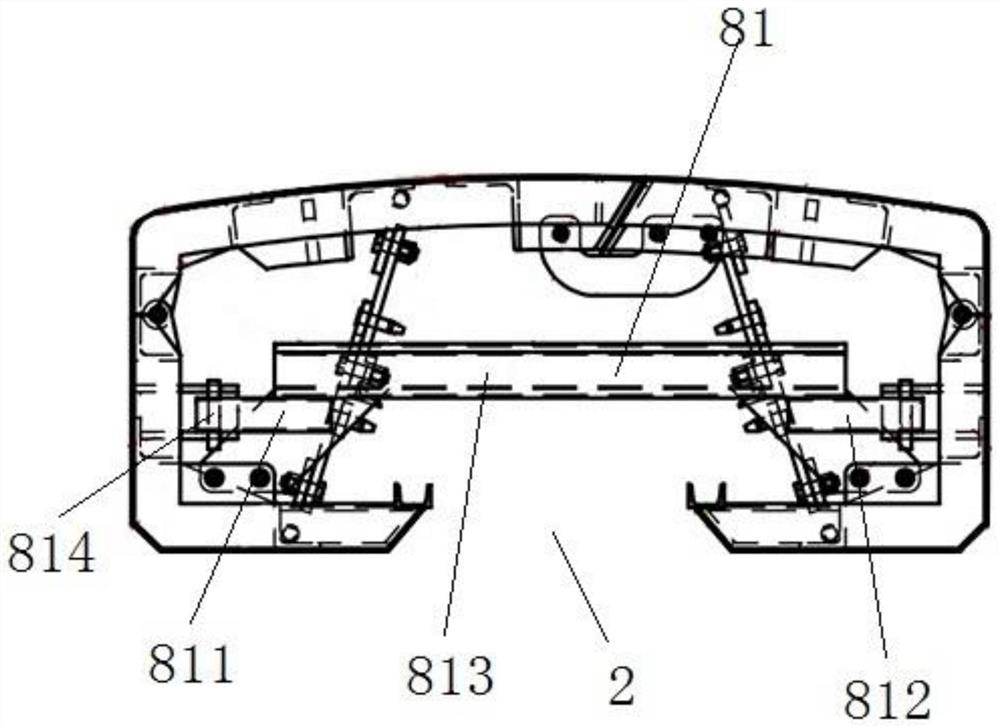

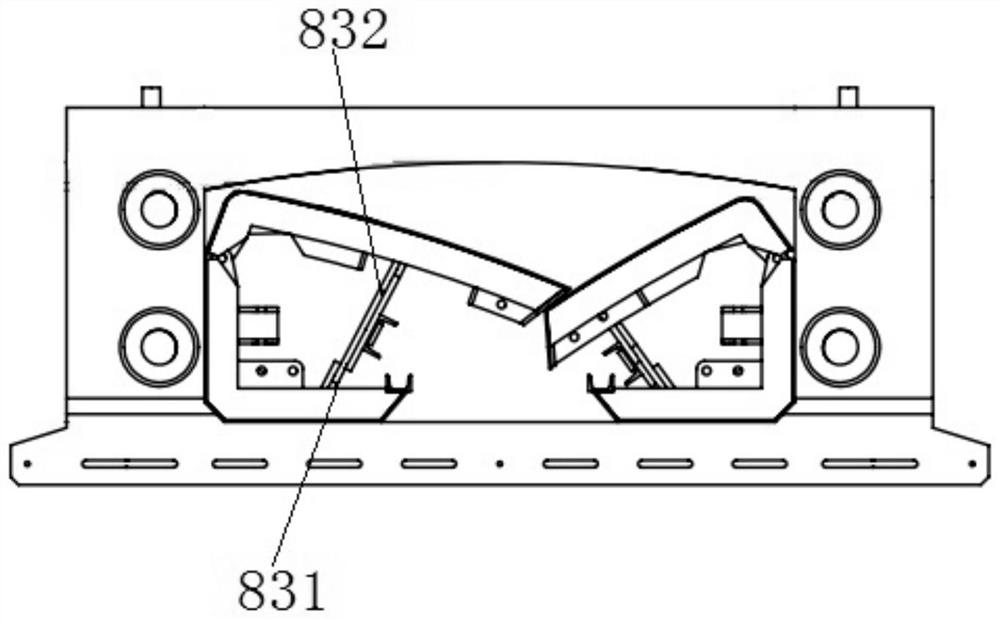

[0075] Wherein, assembling the inner mold and binding the steel bars includes firstly adjusting the length of the vertical supporting device 83, propping up the third template 5 and the fourth template 6; installing the first supporting device 81 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com