Sand foundation dewatering and drainage method

A foundation and sandy soil technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of difficult construction, inapplicability, and difficulty in guaranteeing construction quality, and achieve the effects of ensuring construction quality, long applicable distance, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

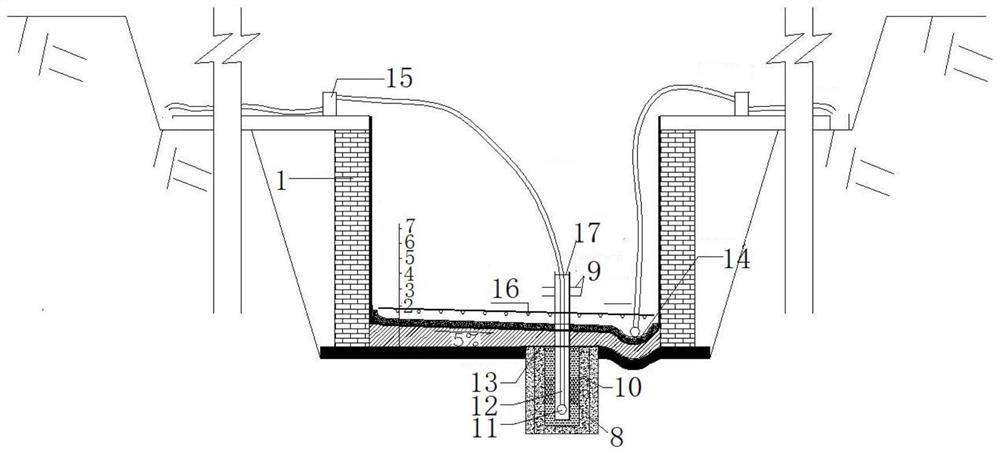

[0043] Substate base residering method, the steps are as follows:

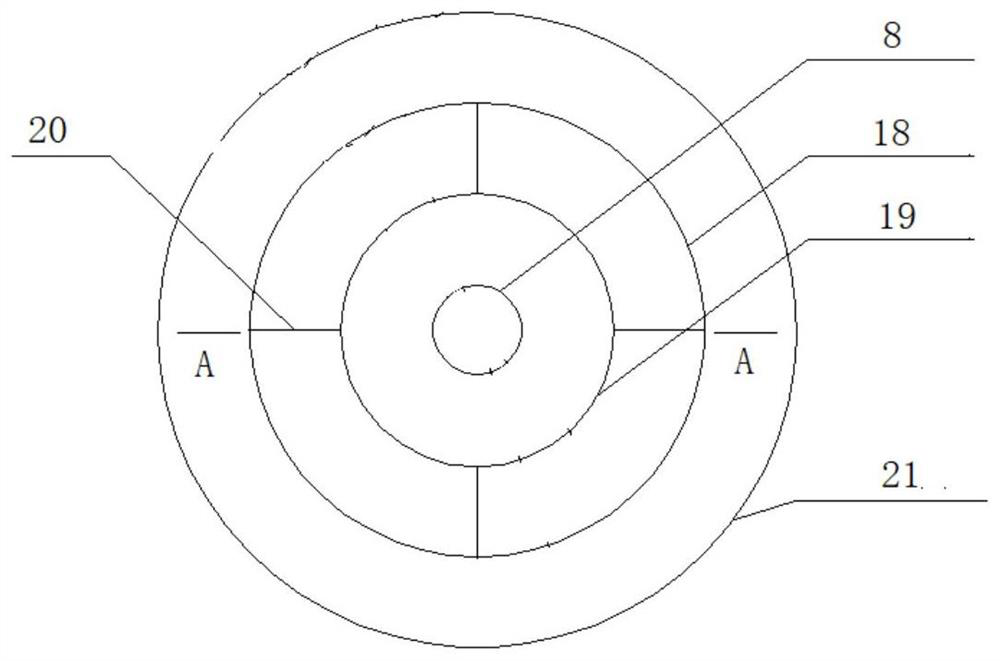

[0044] (1) In the pool bottom of the pit, the bottom of the bottom of the cushion 3 is laid with the second earth wicker 2, and the side wall of the pit is laid. Cave 21 (600mm diameter, depth 800mm);

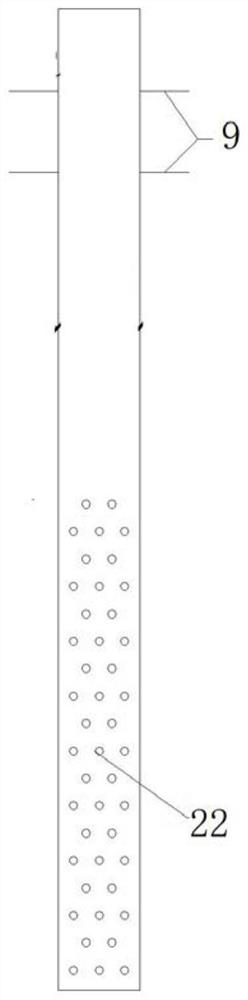

[0045] (2) After the bottom refiner is arranged in the bottom of the pit, arrange it in the pit hole. image 3 and 4 The survey-side refiner layer fabric tool, the peripheral refiner layer fabric manufactured includes a coaxial tooling outer tube 18 and a tool inner tube 19, the inner tube 19 is disposed within the tooling outer tube 18 and the inner tube 19 and the tooling The outer tube 18 is connected by a plurality of positioning reinforcing reinforcing rings perpendicular to the symmetry axis of the tooling outer tube, and the pothole 21 is a gap between the tooling outer tube 18, and the outer tube is perpendicular to the bottom wall of the pit.

[0046] (3) In the housing in the tooling, a vertical arrangemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com