Front panel of transformer coil casting die and fabrication method thereof

A transformer coil and casting mold technology, which is applied in the field of transformers, can solve the problems of high cost, increased transformer manufacturing cost, and difficult panel processing, etc., achieve high flatness, improve fatigue performance, and eliminate stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below:

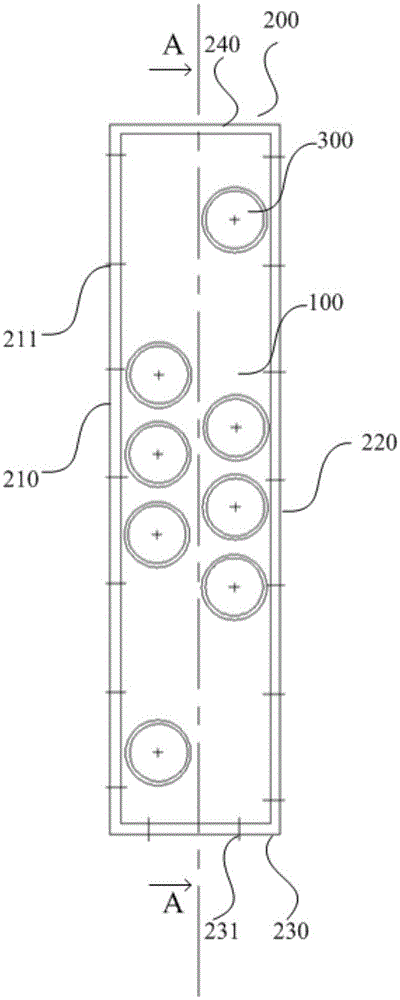

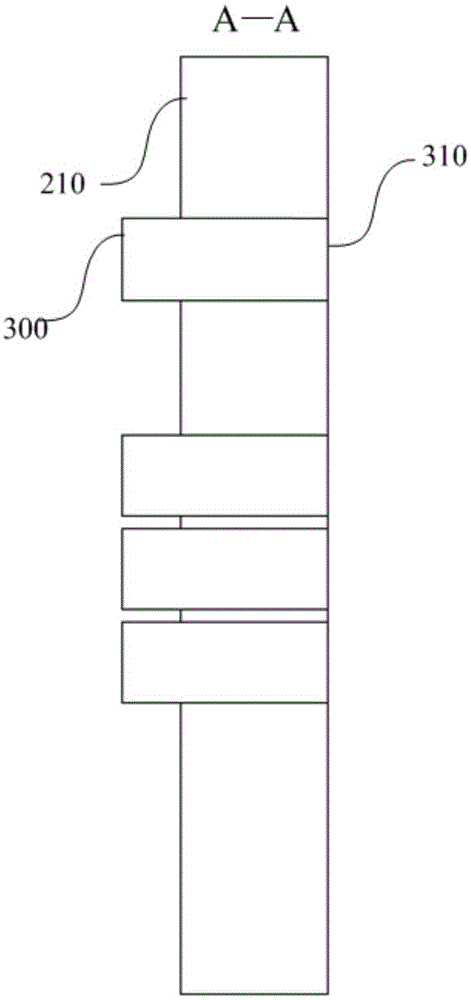

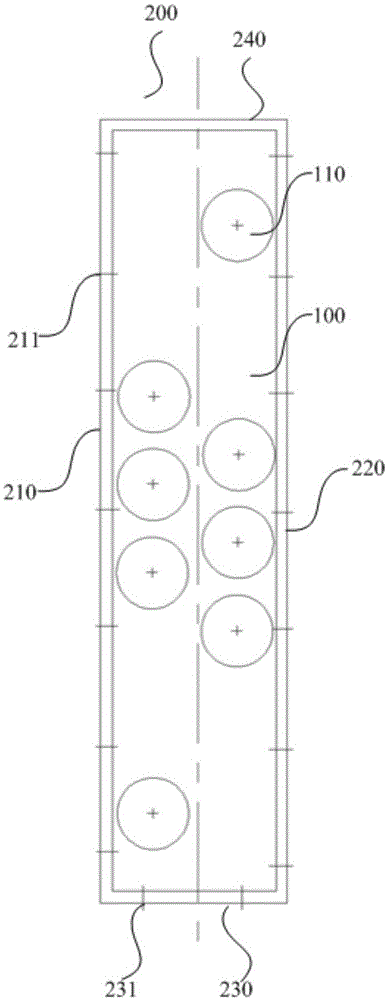

[0033] like Figure 1-3 As shown, the front panel of a transformer coil casting mold includes a bottom plate 100, a plurality of side plates 200 arranged around the bottom plate 100, and a terminal post casting mold 300. Two adjacent side plates 200 are connected, and the bottom plate 100 is provided with coils. The mounting hole 110 communicating with the inner cavity of the casting mold, the terminal casting mold 300 is fixed in the installation hole 110 , and the wiring post casting mold 300 is provided with a pouring port 310 communicating with the inner cavity of the coil casting mold. During casting, the epoxy resin enters from the coil casting mold and flows to the terminal casting mold 300 through the pouring port 310, so that the terminal column is cast and formed. Fixing holes are provided on the side plate 200 for cooperating with screws or bolts to connect and fix with the external struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com