Graphite electrode automatic detection and packaging device

An automatic detection, graphite electrode technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of inconvenient measurement and transportation, potential safety hazards, cumbersome measurement steps, etc., to improve the degree of automation and operation efficiency, improve adaptability Sex, reduce the effect of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

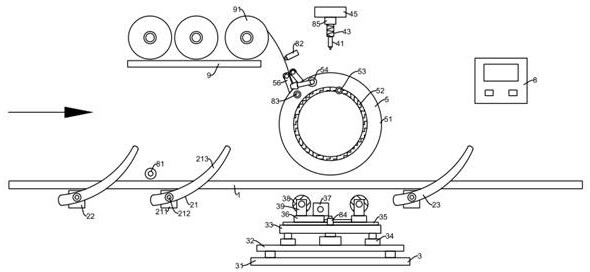

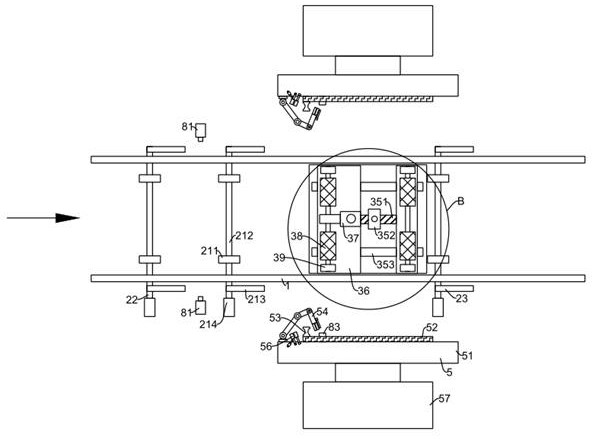

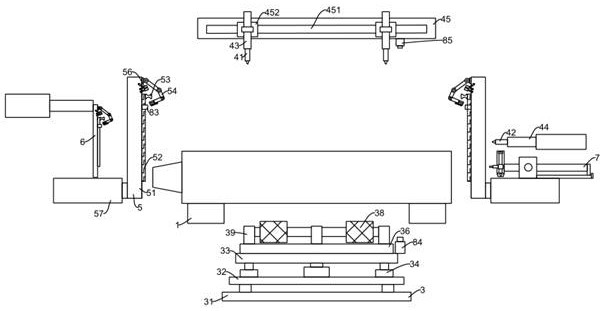

[0034] like Figure 1-Figure 9As shown, the graphite electrode automatic detection packaging device includes a feeding guide rail 1, a bottom support mechanism 3, a PLC controller 8, a first laser range finder 81, a second laser range finder 82 and a third laser range finder 83; In the material conveying direction, the feeding guide rail 1 is set, the bottom supporting mechanism 3 is set under the feeding guiding rail 1, and the first stopper 21 is set at the feeding end of the bottom supporting mechanism 3; the bottom supporting mechanism 3 includes a weighing platform 31, a second Two loading plates 32, the third loading plate 33, the second lifter 34, the third driving motor 37, idlers 38 and the second fixed rod 39; the second loading plate 32 is set above the weighing platform 31, and the second loading A second lifting member 34 is arranged on the plate 32, and the second lifting member 34 is arranged in the vertical direction. A third bearing plate 33 is arranged above ...

Embodiment 2

[0039] like Figure 1-Figure 9 As shown, for the above embodiments, this embodiment optimizes the structure of the guide rail.

[0040] In the present graphite electrode automatic detection packaging device, the feeding guide rail 1 is arranged obliquely downward along the material conveying direction. The inclined downward feeding guide rail 1 facilitates the forward movement of the electrode rod body through the effect of its own gravity, and there is no need to provide a conveying power mechanism, which saves costs.

Embodiment 3

[0042] like Figure 1-Figure 9 As shown, for the above embodiments, this embodiment optimizes the limiting structure.

[0043] In the graphite electrode automatic detection packaging device, a first limiter 21 and a third limiter 23 are respectively set at the feed end and the discharge end of the bottom support mechanism 3, and the first limiter 21 and the third limiter The bit parts 23 are respectively electrically connected to the output control terminals of the PLC controller 8 . During the initial work, the first limiter 21 is in a raised state. When the electrode rod body moves to the first limiter 21, the first limiter 21 limits the electrode rod and suspends the movement; when the bottom supporting mechanism 3 is in the In the "no-load" state, the third limiter 23 is in a raised state, the first limiter 21 slowly descends, the electrode rod slowly rolls to the third limiter 23, and then the first limiter 21 is lifted again, The bottom supporting mechanism 3 then lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com