Heading machine and unilateral gripper shoe device thereof

A technology of roadheader and shoe plate, applied in mining equipment, earth-moving mining, tunnels, etc., can solve the problem of auxiliary support shoes occupying installation space and other problems, and achieve the effect of small occupied space and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

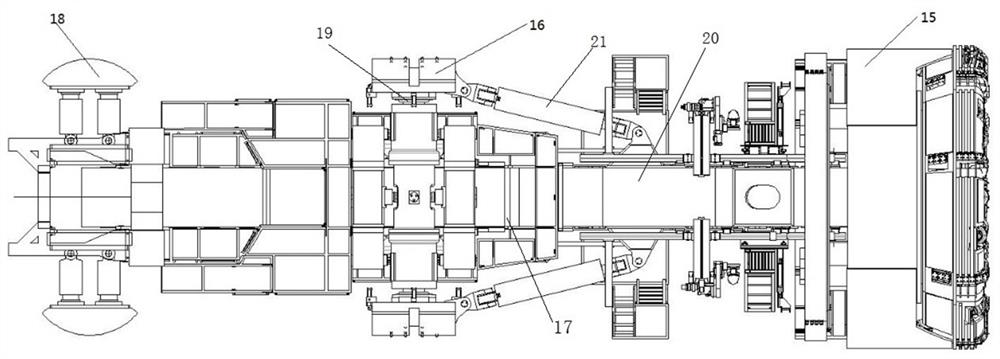

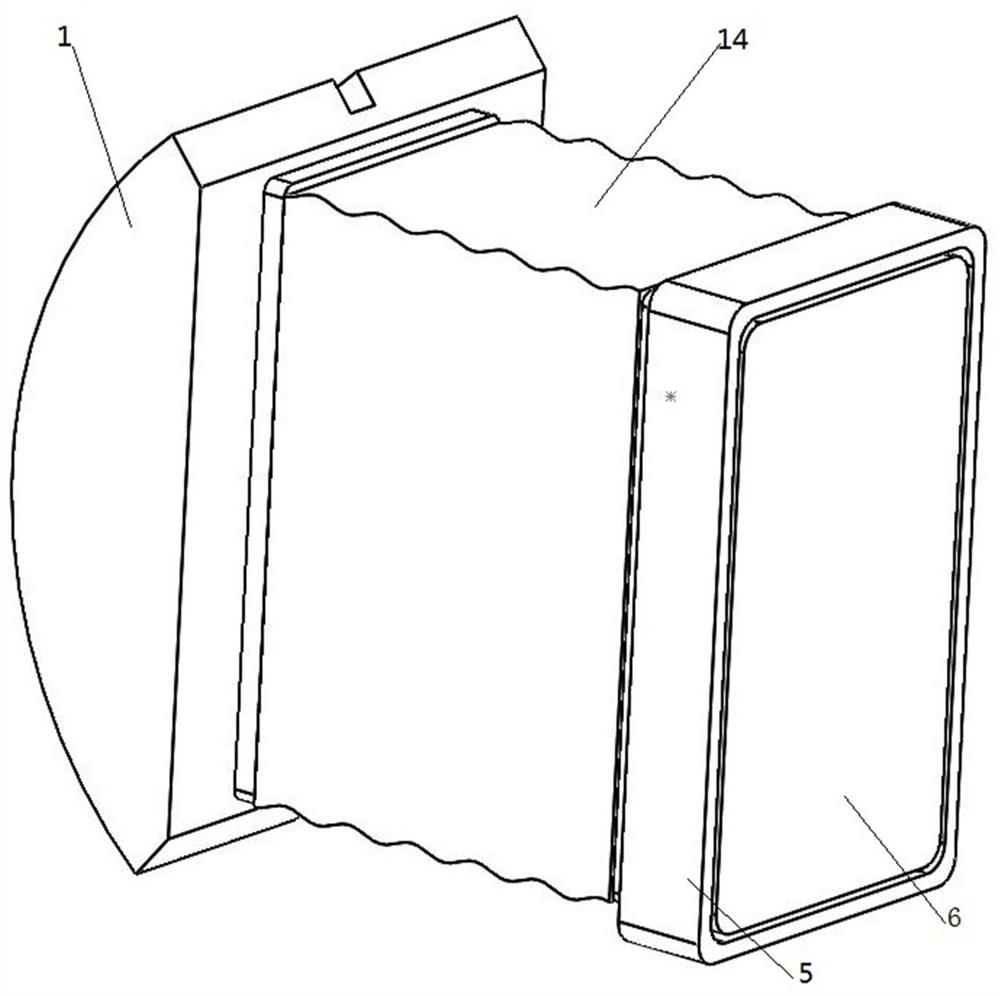

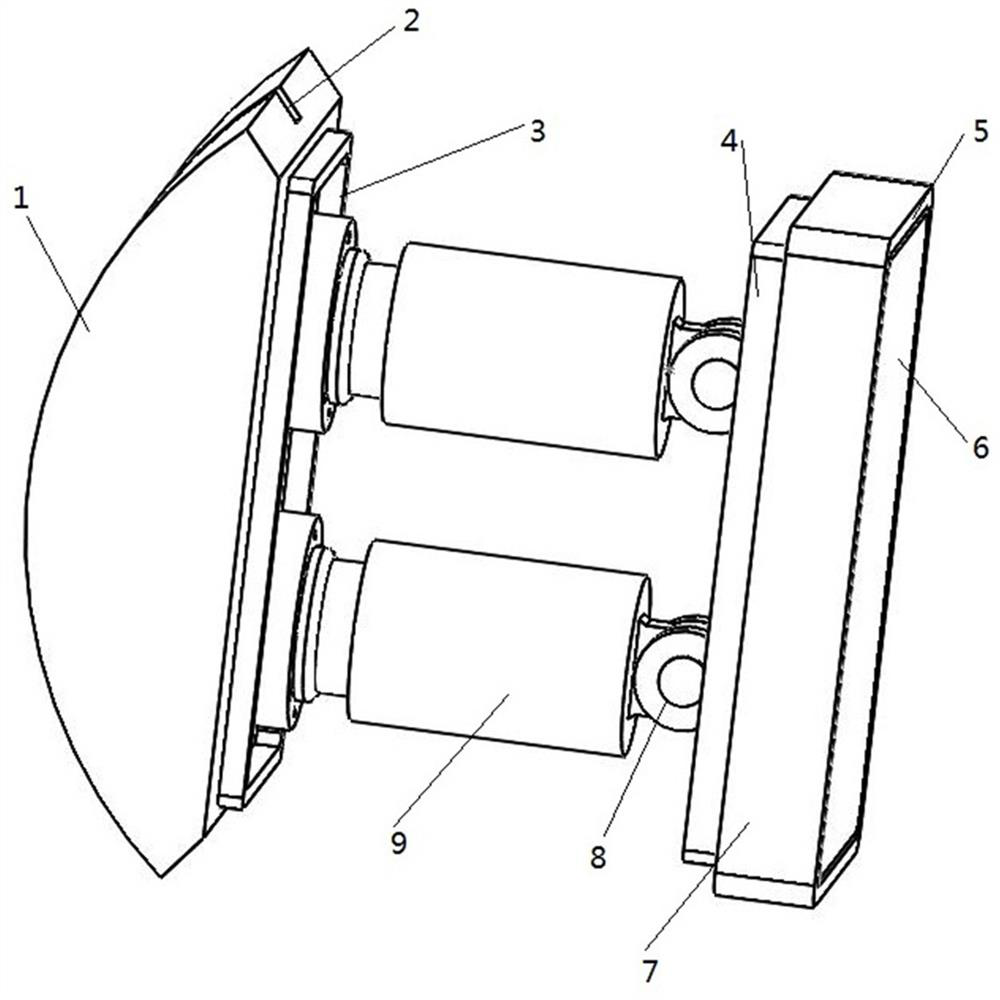

[0074] The roadheader provided in this embodiment is a hard rock roadheader. The difference between it and the hard rock roadheader in the prior art is that it is additionally equipped with a mobile spreader shoe unit, which includes two single-side braces. Shoe device, two unilateral support shoe devices can be symmetrically installed on both sides of the main body of the roadheader, which can form a temporary support and provide support and reaction force. When the main support shoe on the hard rock roadheader is sufficient to provide support and reaction force, the mobile support shoe unit can be directly removed to save corresponding space.

[0075] Such as Figure 1 to Figure 4 As shown, the hard rock roadheader in this embodiment specifically includes a roadheader main body 17, and the roadheader body 17 includes a main beam 20, a front shield body 15 is arranged at the front end of the main beam 20, a cutter head is arranged on the front shield body 15, and a 20 is pro...

specific Embodiment 2

[0096] The main difference between it and Embodiment 1 is that in Embodiment 1, the telescopic driving structure adopts superconducting electromagnets to drive the shoe to extend outward. In this embodiment, the telescoping drive structure can directly use a hydraulic cylinder, and the hydraulic cylinder can be used on the existing roadheader corresponding to the main spreader cylinder, and it is necessary to pay attention to the corresponding configuration of the hydraulic oil circuit. When a hydraulic cylinder is used, the hydraulic cylinder can be directly used to drive the telescopic movement of the shoe plate.

specific Embodiment 3

[0098] The main difference between it and Embodiment 1 is that in Embodiment 1, the detachable connection structure on the connection base is a fixed electromagnet, which is energized and fixed on the main beam by adsorption. In this embodiment, the detachable connection structure on the connection seat is a connection plate, and the connection plate is provided with a bolt connection structure for detachable connection with the main beam. Due to the large number of installation bolts, this bolt installation method relatively low efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com