Tunnel maintenance robot

A technology of robots and tunnels, applied in tunnels, tunnel linings, instruments, etc., can solve the problems of low machine intelligence, inability to repair tunnel diseases, unfavorable health, etc., and achieve the effect of improving intelligence and learning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

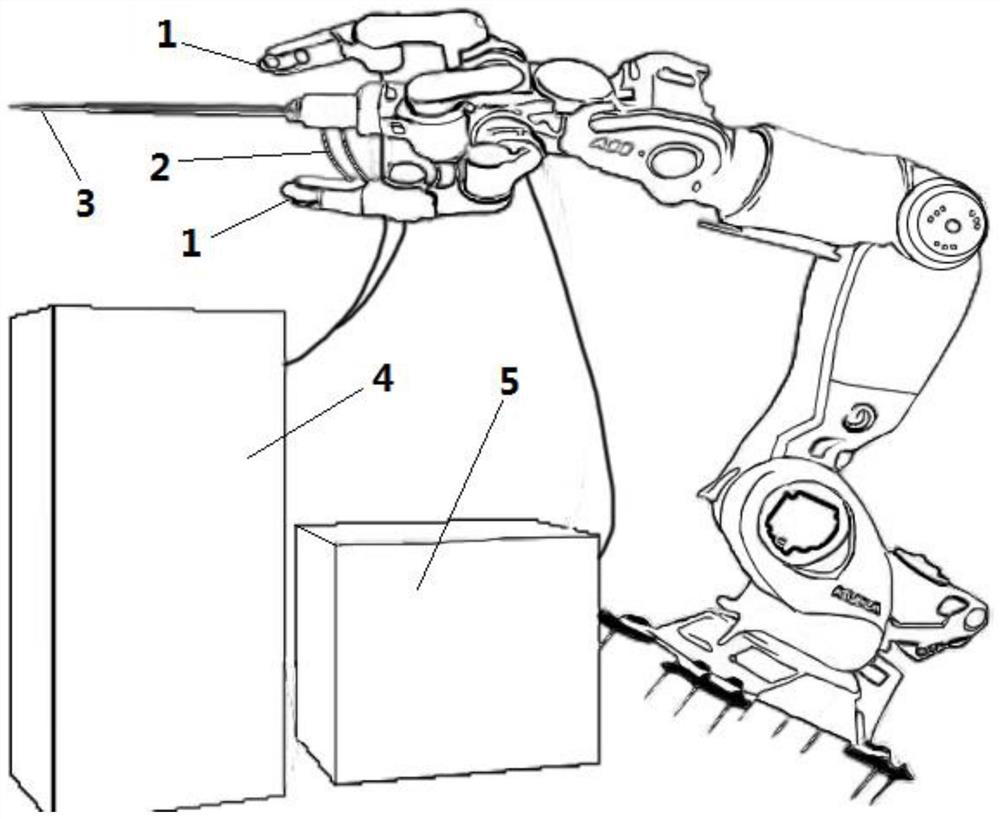

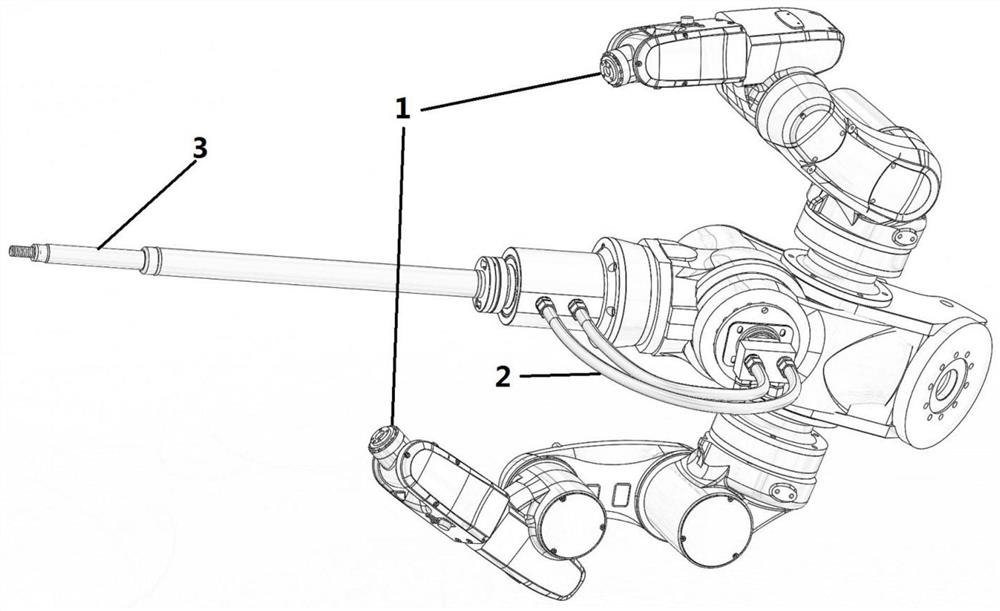

[0050] Such as figure 2 As shown, the tunnel maintenance robot described in the present invention includes a depth camera 1 , a transport conduit 2 , and an injection nozzle 3 . Its main structure is a 6-DOF mechanical arm that can translate in 3 directions and rotate around 3 axes. The depth camera 1 adopts three-dimensional imaging using binocular stereo vision three-dimensional imaging technology. A depth camera 1 is installed on the left and right sides of the front end of the mechanical arm, so as to realize the real-time collection of tunnel surface disease information by 3D machine vision during the tunnel maintenance process, and transmit the disease information on the basis of qualitative analysis of the tunnel lining disease The two-stage progressive network maintenance model is further analyzed to determine the maintenance location and maintenance angle. The front end of the mechanical arm is equipped with an injection nozzle 3, the injection nozzle 3 is connecte...

Embodiment 2

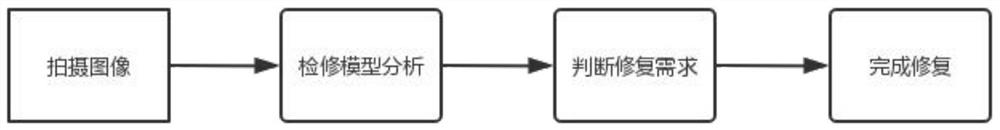

[0052] This embodiment is an example of the operation steps of the tunnel maintenance robot, which mainly includes four stages of capturing images, analyzing the maintenance model, judging the repair requirement and completing the repair.

[0053] (1) Capture images: The image capture of the tunnel maintenance robot can be done on the robotic arm. Please refer to Figure 3, there are two depth cameras 1 on the left and right sides of the robotic arm, and these two depth cameras 1 complete the task of capturing images;

[0054] (2) Overhaul model analysis: the depth image taken by the depth camera 1 is sent to the processing center 4 for processing. The processing center 4 uses a two-stage progressive network framework to analyze the depth image. see Figure 4 , the general maintenance process based on the two-stage progressive network architecture mainly includes two stages, which are to determine the repair position and determine the repair angle. In the stage of determinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com