Fiber grating type intelligent diagnosis method and system for variable-pitch flange and blade of wind turbine generator

A fiber grating and wind turbine technology, applied in wind turbines, monitoring of wind turbines, engines, etc., can solve problems such as the inability to identify pitch flanges and unclear fault diagnosis mechanisms, and achieve improved engineering application value, reliable functions, and diagnostics Mechanistically clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 An Intelligent Diagnosis Method for Pitch Flange Bolts and Blades of Wind Turbine Units

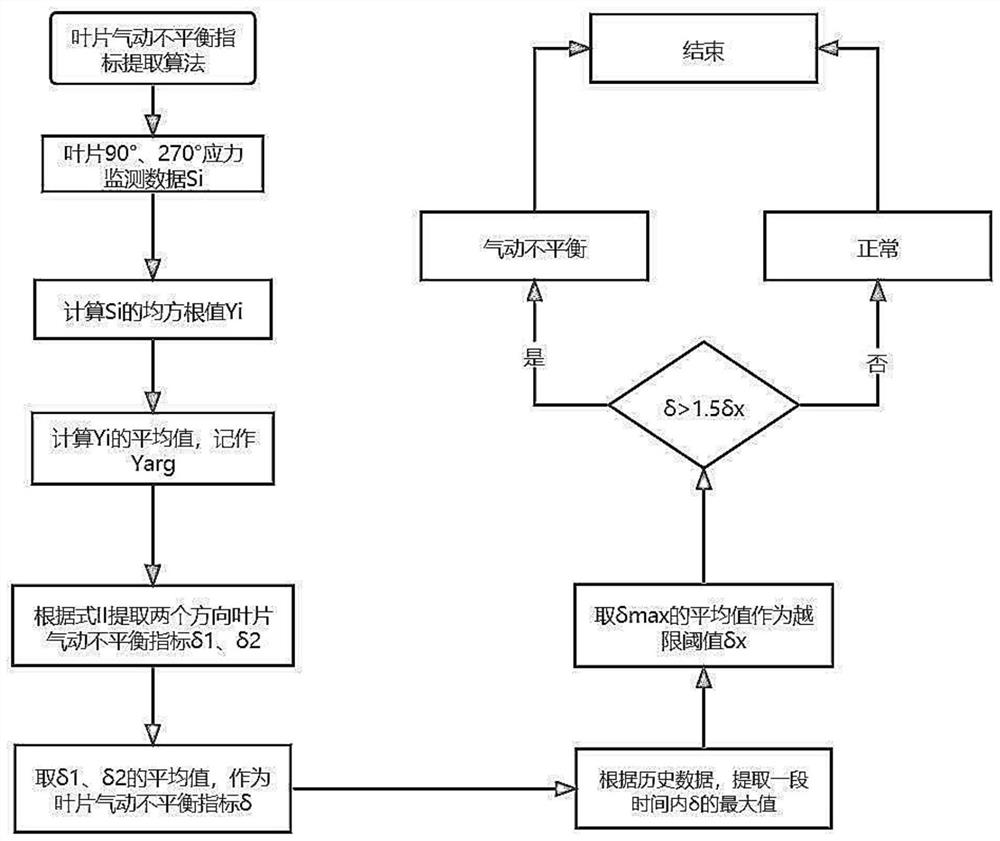

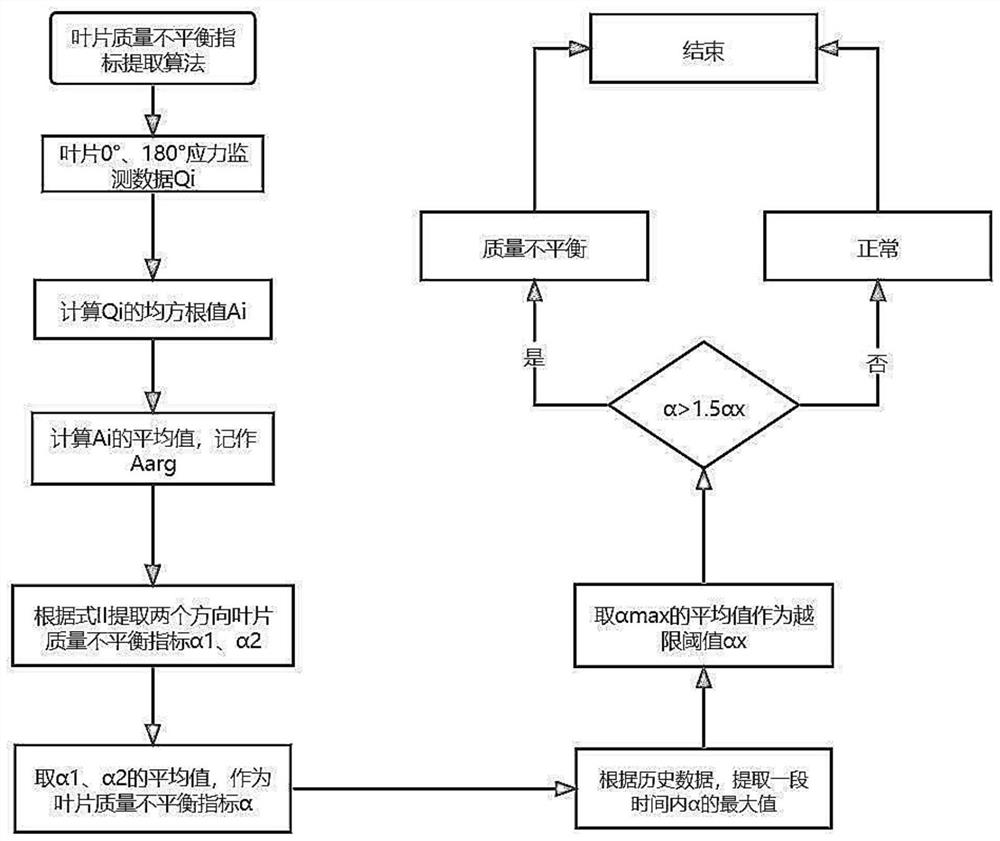

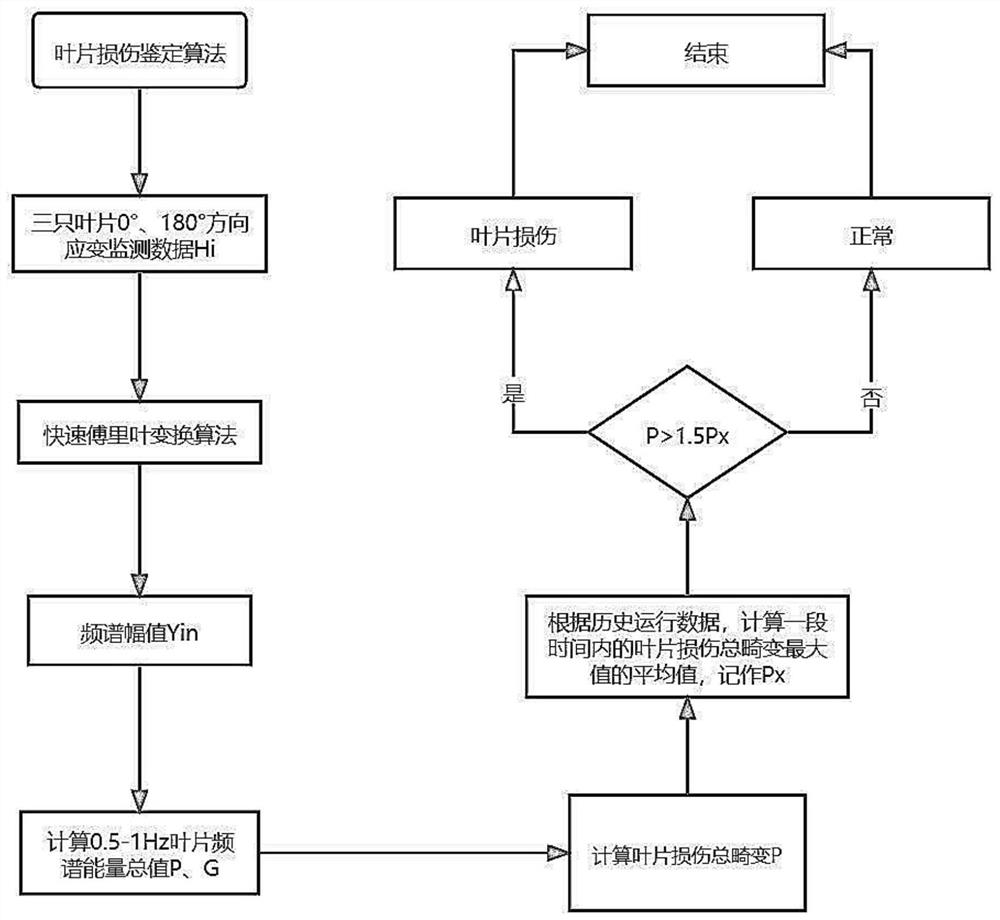

[0031] Such as Figure 1-4 As shown, a fiber grating type wind turbine pitch flange, blade intelligent diagnosis method, including blade fault diagnosis algorithm and its figure 1 The algorithm for extracting the aerodynamic unbalance index of the blade shown, figure 2 The blade mass imbalance index extraction algorithm shown and image 3 The blade damage identification algorithm shown can identify blade aerodynamic unbalance, mass unbalance, blade damage and other faults in real time; it includes such as Figure 4 The state monitoring algorithm of the pitch flange bolts and its secondary over-limit threshold are shown, and the faults such as bolt looseness and fracture can be judged in real time.

[0032] Such as figure 1 The wind turbine blade aerodynamic unbalance index extraction algorithm calculates the fiber grating strain sensing data in the 90° and 270° di...

Embodiment 2

[0085] Embodiment 2 An Intelligent Diagnosis System for Pitch Flanges and Blades of Wind Turbines

[0086] This embodiment provides an intelligent diagnosis system for wind turbine pitch flanges and blades according to Embodiment 1, such as image 3 As shown, the system includes the following modules:

[0087] Blade fault diagnosis module: According to the blade fault diagnosis algorithm and its subordinate blade aerodynamic imbalance index extraction algorithm, blade mass imbalance index extraction algorithm, and blade damage identification algorithm, a blade fault diagnosis module is constructed, which receives blade fiber grating strain monitoring in real time Data, analyze and diagnose the current fault status of the blades of the unit, and complete the judgment of blade faults.

[0088] Pitch flange bolt state monitoring module: According to the pitch flange bolt filling monitoring algorithm and its secondary threshold value, the pitch flange bolt state monitoring module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com