Sodium sulfide drying system

A drying system and sodium sulfide technology, applied in the direction of sulfur compounds, dry solid materials, dry gas arrangement, etc., can solve problems such as crystallization adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

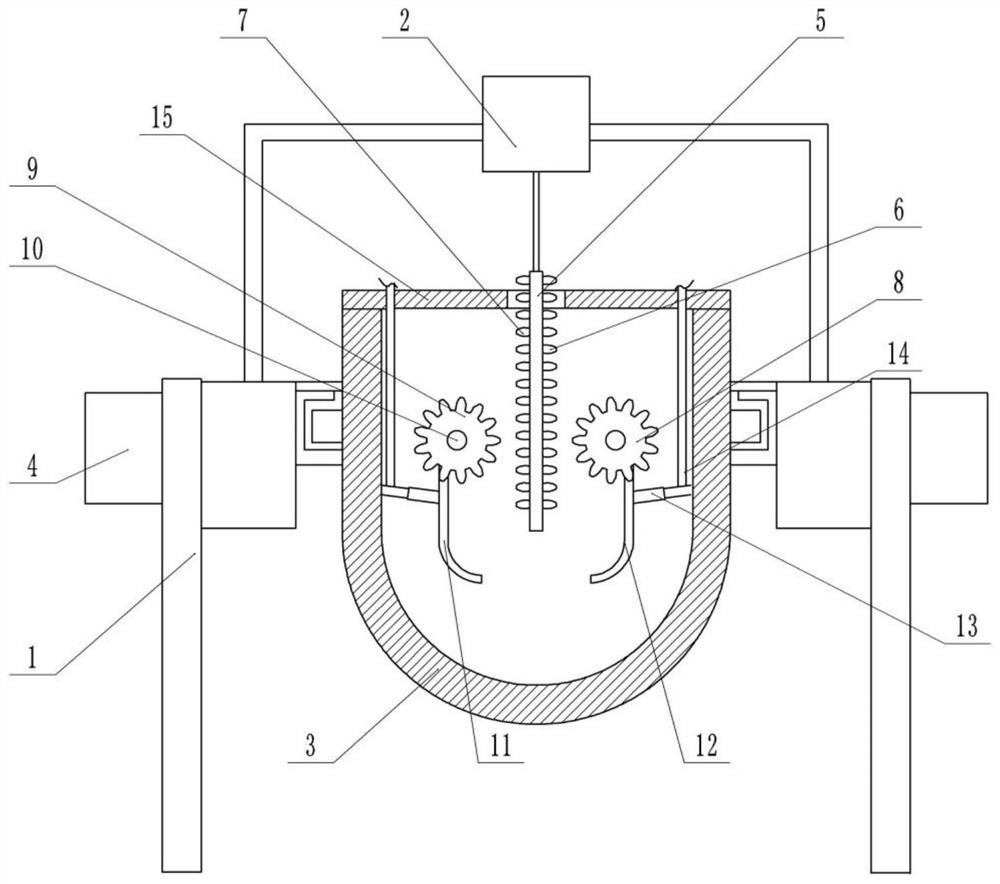

[0020] as attached figure 1 As shown, a sodium sulfide drying system includes: a frame 1 and a drying pot 3, handles are provided on both sides of the drying pot 3, the handles are convenient for fixing the drying pot 3 on the frame 1, and it is also convenient to move the drying pot 3. The drying pot 3 is fixedly installed on the frame 1 by bolts and handles. The drying pot 3 is provided with an exhaust pipe, and the exhaust pipe is wound on the surface of the drying pot 3 . The water vapor is evaporated by drying, and then discharged through the exhaust pipe to heat the outer surface of the drying pot 3, and the waste heat is used to accelerate the drying efficiency of sodium sulfide, reduce energy waste, and save energy.

[0021] It also includes: a moving rod 5, a first gear 8, a second gear 9, a telescopic tube 13 and a cylinder 2 that drives the moving rod 5 to move vertically; the cylinder 2 is fixedly installed on the frame 1 through a bracket. The moving rod 5 is fi...

Embodiment 2

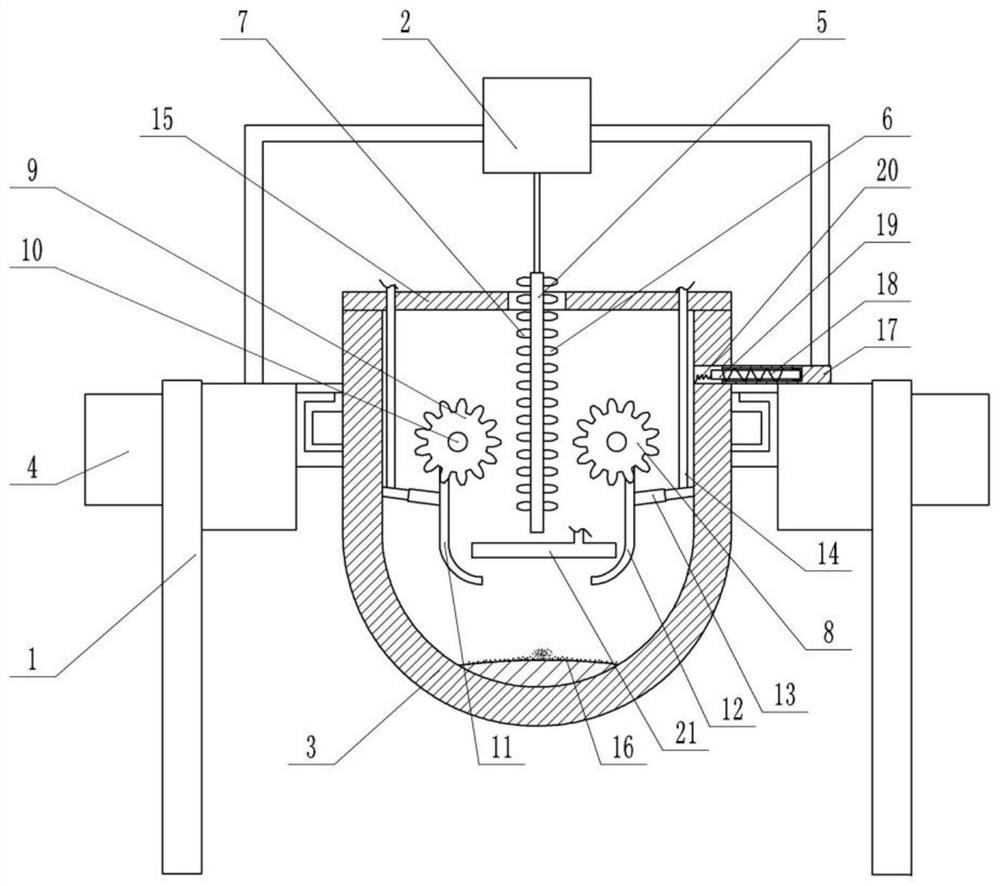

[0030] As shown in Embodiment 2, the difference between this embodiment and Embodiment 1 lies in the hot blast device. The hot blast device 4 includes a waste gas pipe, and the waste gas pipe is used to transport the waste gas produced by the sodium sulfide roasting system. An electric valve is provided, and the electric valve is used to control the exhaust of the waste gas pipe, and the switch of the electric valve is electrically connected with the controller. The drying pot 3 is provided with a briquetting block 21 and a hydraulic cylinder for moving the briquetting block 21 , and the briquetting block 21 is used to break the massive sodium sulfide at the bottom of the drying pot 3 . The hydraulic cylinder control switch is electrically connected with the controller. The bottom of the inner wall of the drying pot 3 is provided with an upward arc 16 , and the direction of the hot air generated by the first heating pipe 12 and the second heating pipe 11 is opposite to the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com