Dual-system absolute value encoder device and use method thereof

An absolute encoder and dual-system technology, applied in the encoder field, can solve the problems of inability to judge in time, wrong solution, low cost, etc., and achieve the effect of being beneficial to mass production and installation, improving position accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

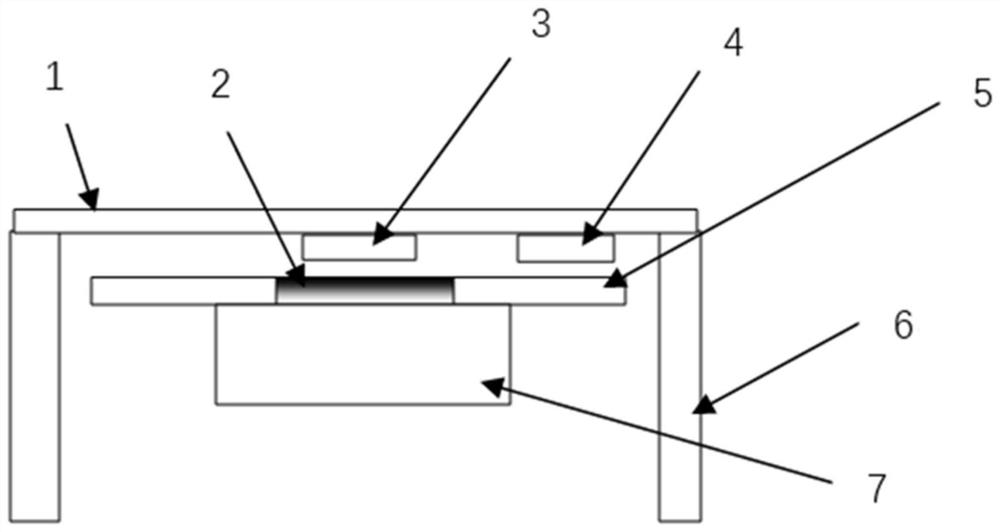

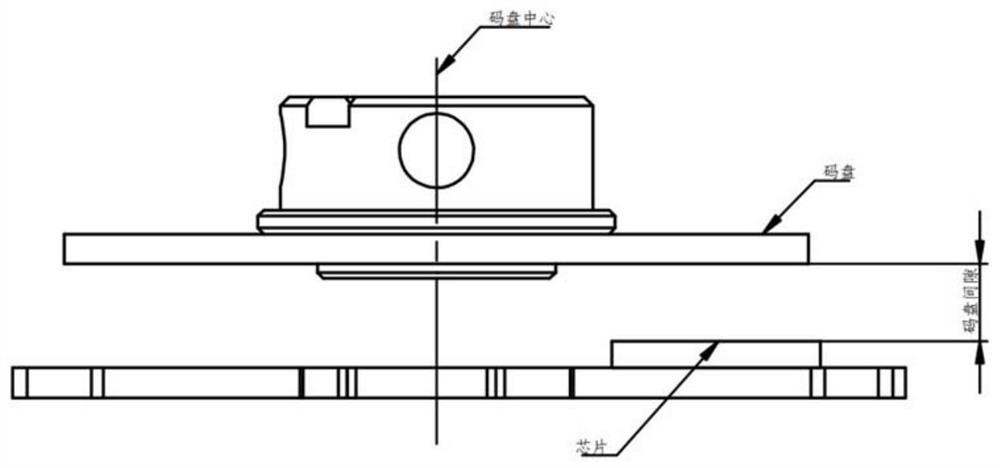

[0037] Such as figure 1 As shown, a dual-system absolute encoder device includes a PCB board 1, a magnet 2, a magnetic induction chip 3, a reflective induction chip 4, an incremental reflective code disc 5, an encoder bracket 6 and a code disc support 7; The PCB board 1 is placed on the encoder bracket 6 with the component side facing down; the magnet 2 is embedded in the center of the incremental reflective code disc 5; the magnetic induction chip 3 is located on the PCB board 1 and connected to the magnet 2 Coaxial installation; the incremental reflective code wheel 5 is placed on the code wheel holder 7; the reflective sensor chip 4 is located on the PCB board 1, wherein the reflective sensor chip 4 and the outer ring of the incremental reflective code wheel 5 relatively.

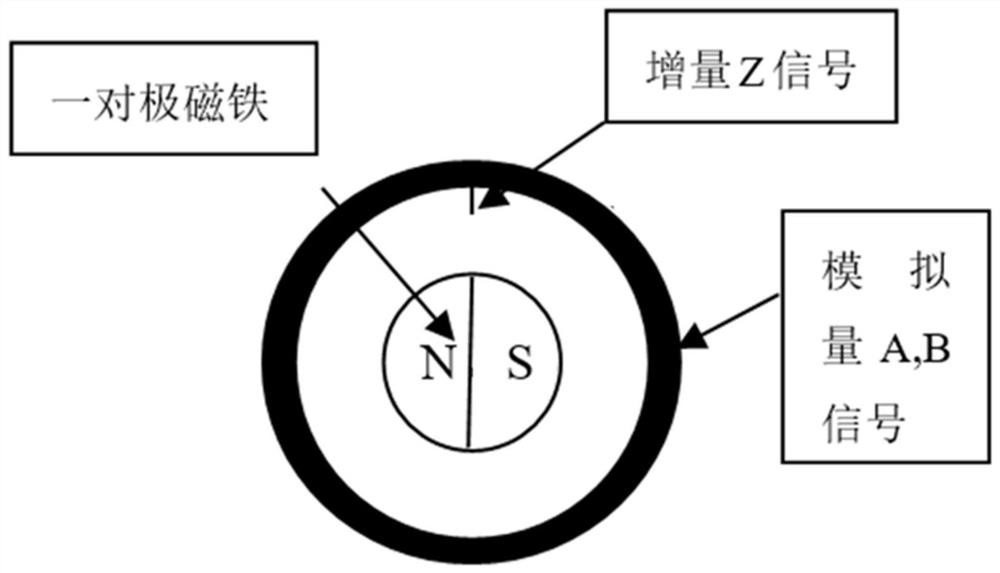

[0038] The dual-system absolute encoder device of the present invention includes a magnetic single-turn absolute encoder and an incremental reflective encoder, and the two encoders are mutually switched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com