Shaker for pesticide residue detection that can adapt to different types of reagent bottles

A technology adapted to different reagent bottles, applied in the field of pesticide residue detection equipment, can solve problems such as large losses and pollution, loose Schott bottles, bottle ruptures, etc., to prevent collision, easy to use, and ensure the effect of shock effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

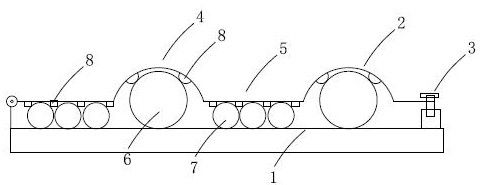

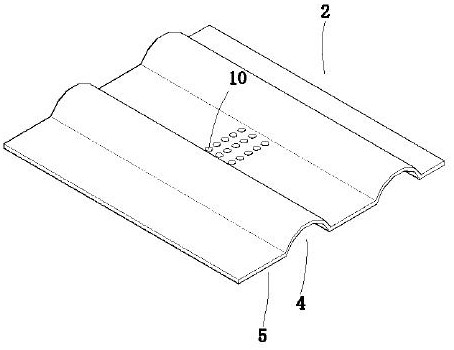

[0029] like Figure 1-2 As shown in the figure, a shaker for pesticide residue detection that can adapt to different types of reagent bottles includes a vibration base and a bearing basket arranged on the vibration base. The bearing basket includes a bearing platform 1 and a cover plate 2, and the cover plate is a wavy curved plate , one side of the cover plate and the bearing platform are hinged, and the other side is connected with the bearing platform through the locking device 3 which can be opened and closed; The second accommodating part 5 at the trough position of the curved plate; in this embodiment, the lower side of the second accommodating part is a plane;

[0030] When the cover plate is closed, the distance between the top of the first accommodating part and the bearing platform is adapted to the outer diameter of the bottle body of the Schott bottle, and the distance between the top of the second accommodating part and the bearing platform is adapted to the outer...

Embodiment 2

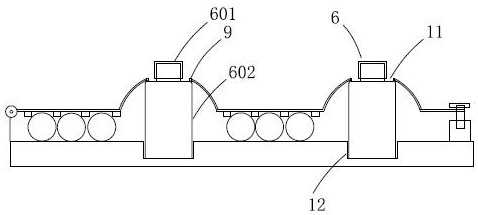

[0039] like Figure 3-4 As shown, it is similar to Embodiment 1, except that the top surface of the first accommodating part is machined with a plurality of first through holes 11 along the length direction, the first through holes are provided with annular spacers 9, the first The diameter of the through hole is larger than the outer diameter of the lid 601 of the SCHOTT bottle and smaller than the outer diameter of the bottle body of the SCHOTT bottle, so that the first through hole can be clamped on the upper part of the SCHOTT bottle to fix the SCHOTT bottle in a standing position.

[0040]The upper surface of the bearing platform is provided with limit grooves 12 with the same number as the first through holes, and each limit groove corresponds to a first through hole; the mouth of the limit groove is adapted to the diameter of the Schott bottle, and The limiting groove is disposed directly below the corresponding first through hole; the depth of the limiting groove is eq...

Embodiment 3

[0043] like Figure 5 As shown, it is similar to Embodiment 2, except that the diameter of the bottom of the limiting groove is larger than the diameter of the mouth, and the bottom of the limiting groove is a convex surface 13 .

[0044] A striker 14 is arranged in the limit groove, and the diameter of the striker is less than 1 / 2 of the difference between the diameter of the bottom of the limit groove and the diameter of the mouth.

[0045] The convex surface enables the bumper to automatically stop at the bottom edge of the limit groove when the shaker is in a static working state, which will not affect the insertion of the Schott bottle.

[0046] When the shaker is working, the impact beads are shaken and hit the Schott bottle, which makes the Schott bottle generate additional vibration, which helps the sample sticking to the bottom of the inside of the Schott bottle to escape from the bottle wall, and can also strengthen the shaking effect of the shaker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com