Unmanned aerial vehicle full life cycle warehouse management system and method

A warehouse management system and full life cycle technology, applied in the field of UAV full life cycle warehouse management system, can solve problems such as unbalanced battery usage, affecting inspection efficiency, equipment management confusion, etc., to reduce workload and improve storage. Take the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

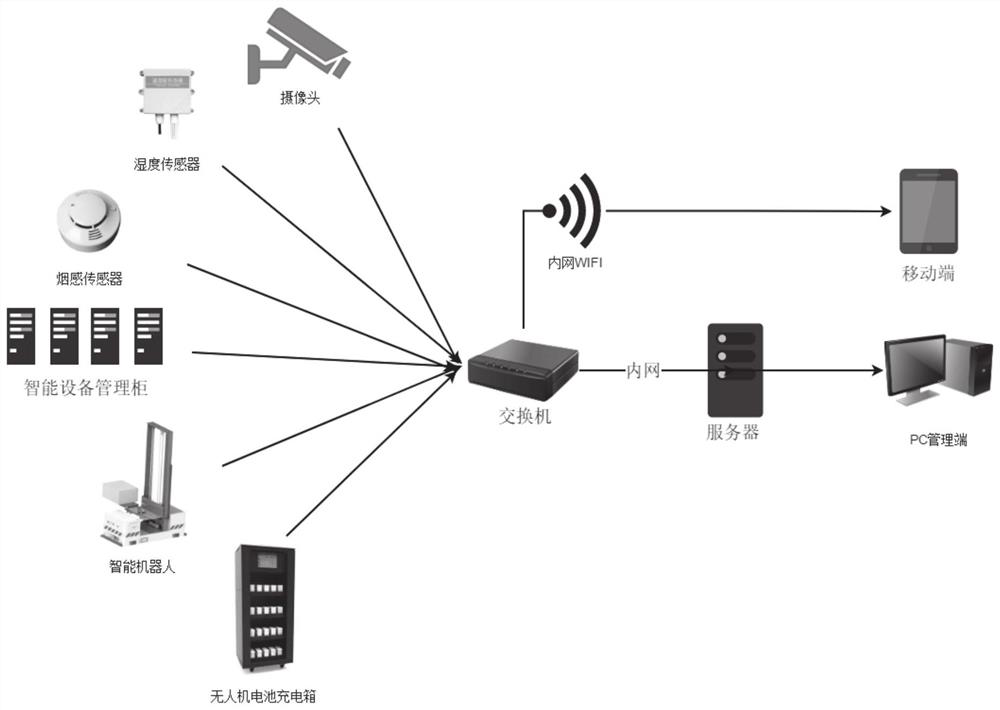

[0056] The purpose of this embodiment is to provide a warehouse management system for the whole life cycle of drones.

[0057] A warehouse management system for the whole life cycle of drones, including:

[0058] UAV storage module, which is used to automatically access the UAV body by using a storage robot;

[0059] The battery charging module includes an explosion-proof cabinet, a fingerprint identification unit and a safety protection unit, which are used for modular charging of the drone battery, and based on an intelligent push algorithm to push the battery with the best performance;

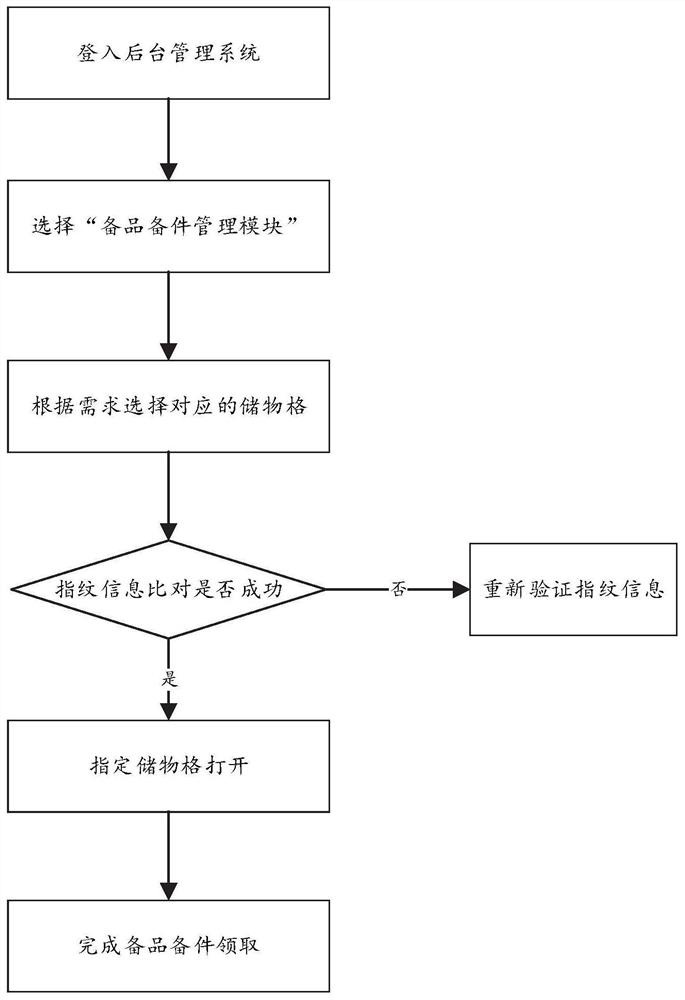

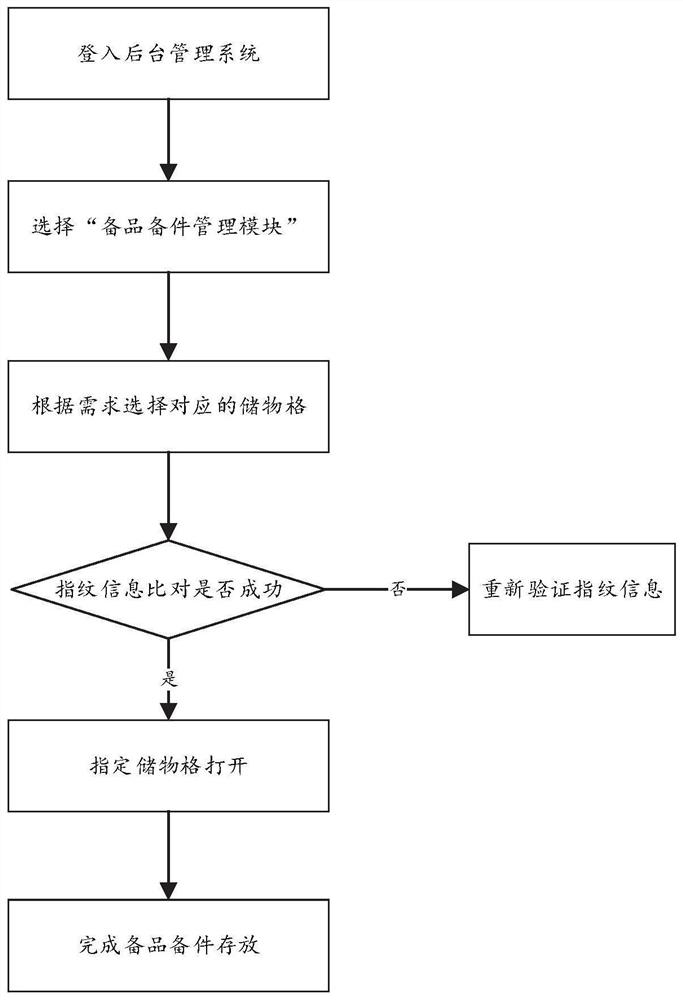

[0060] Spare parts management module, which is used to classify and store the relevant spare parts of the drone;

[0061] Background management module, which is used to issue control commands to the UAV storage module, battery charging module and spare parts management module, and analyze and process the data information from each module;

[0062] Among them, the drone body, battery and s...

Embodiment 2

[0099] The purpose of this embodiment is to provide a storage management method for the full life cycle of UAVs, which utilizes the above-mentioned storage management system for the full life cycle of UAVs. The method includes:

[0100] Bind the drone body, battery and spare parts with the operation and maintenance team;

[0101] Based on the UAV storage module, the battery charging module and the spare parts management module, the access and charging of the components of the UAV are realized;

[0102] During the access process of each part of the drone, the secondary verification of the corresponding personnel is required in advance;

[0103] Based on the background management module, the command issuance and data processing of each module are realized, and the warehouse management of the whole life cycle of the drone is realized.

[0104] In further embodiments, there is also provided:

[0105] The storage management system and method for the full life cycle of UAVs provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com