Generator rotor claw pole angle control device

A generator rotor and angle control technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as high requirements for the shape of claw poles, difficult automatic flow operation, and complex tooling structure, etc., to achieve Convenient and efficient movement, convenient tooling replacement and adjustment, and improved dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

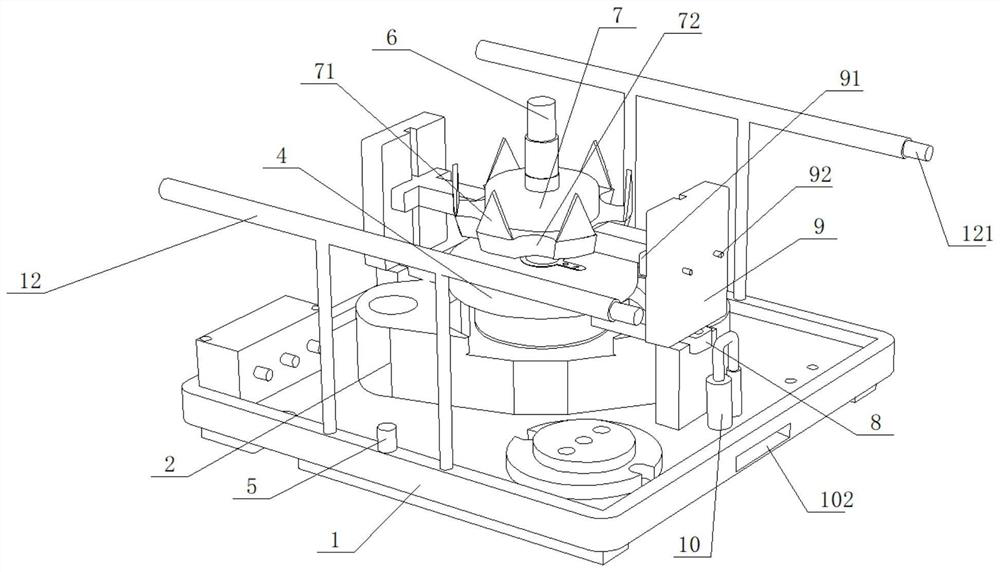

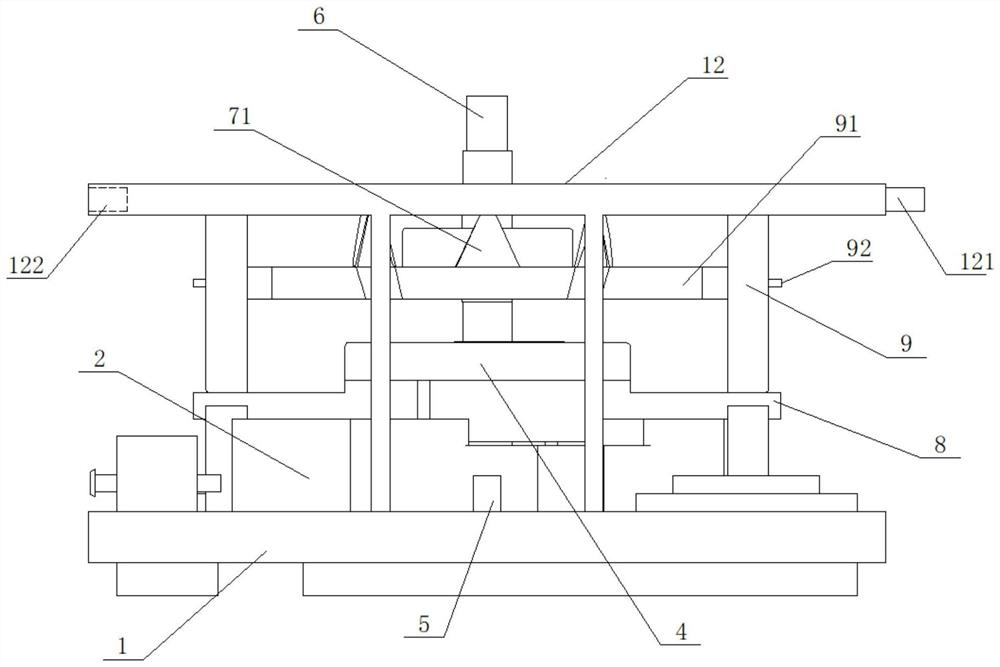

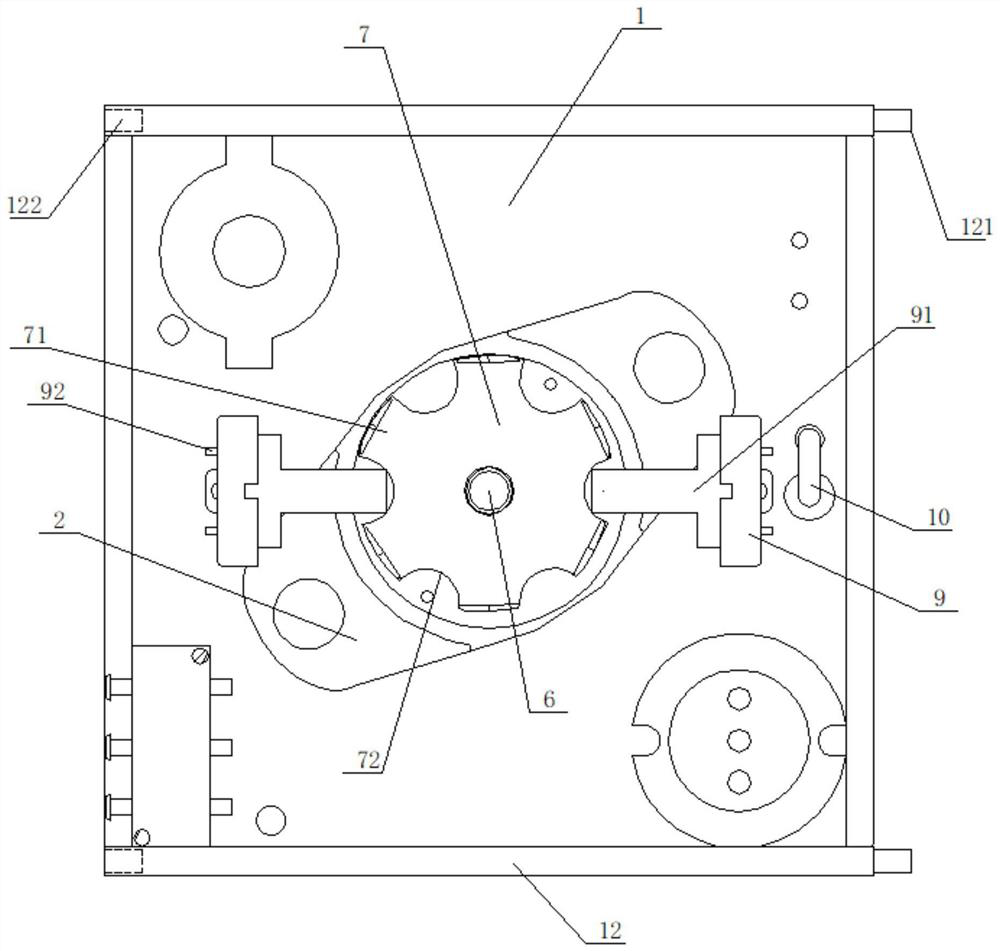

[0038] as attached figure 1 to attach Figure 4 As shown, the present invention provides a generator rotor claw pole angle control device, which includes an assembly line tray 1 and a base 2. It is characterized in that a socket 101 is installed on the left side of the assembly line tray 1, and a socket 101 is installed on the right side of the assembly line tray 1. Socket 102, the upper part of the assembly line tray 1 is provided with a base 2.

[0039] as attached Image 6 to attach Figure 8 As shown, in the above embodiment, specifically, a fixed drive motor 5 is installed on the upper side of the assembly line tray 1, and a drive shaft 51 is provided at the bottom of the fixed drive motor 5, and helical gears are installed at the bottom of the drive shaft 51. One 52 , the side of the first helical gear 52 is meshed with the second helical gear 53 , and the second helical gear 53 is fixedly mounted on the first driven shaft 54 .

[0040] as attached figure 1 to att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com