Rubbing and air-blowing integrated automatic feeding sunflower thresher

An automatic feeding and integrated technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of unsatisfactory, high labor intensity, low efficiency, etc., and achieve the effect of reliable grasping, efficient transportation, and accurate process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

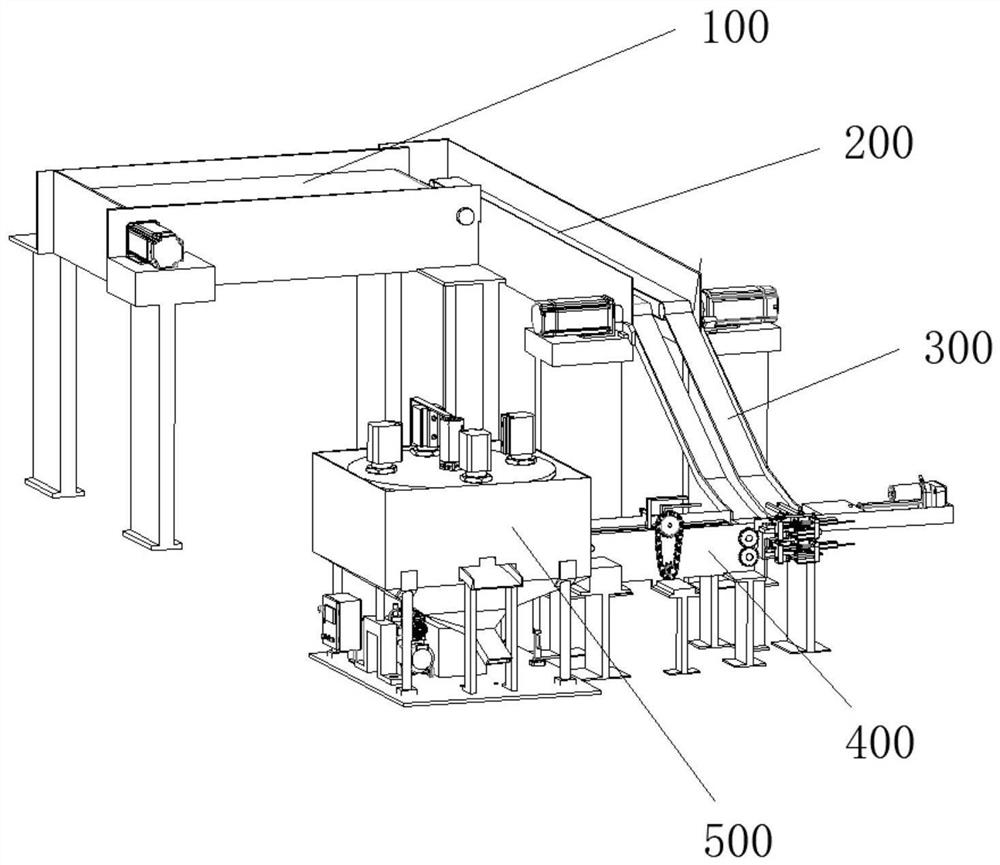

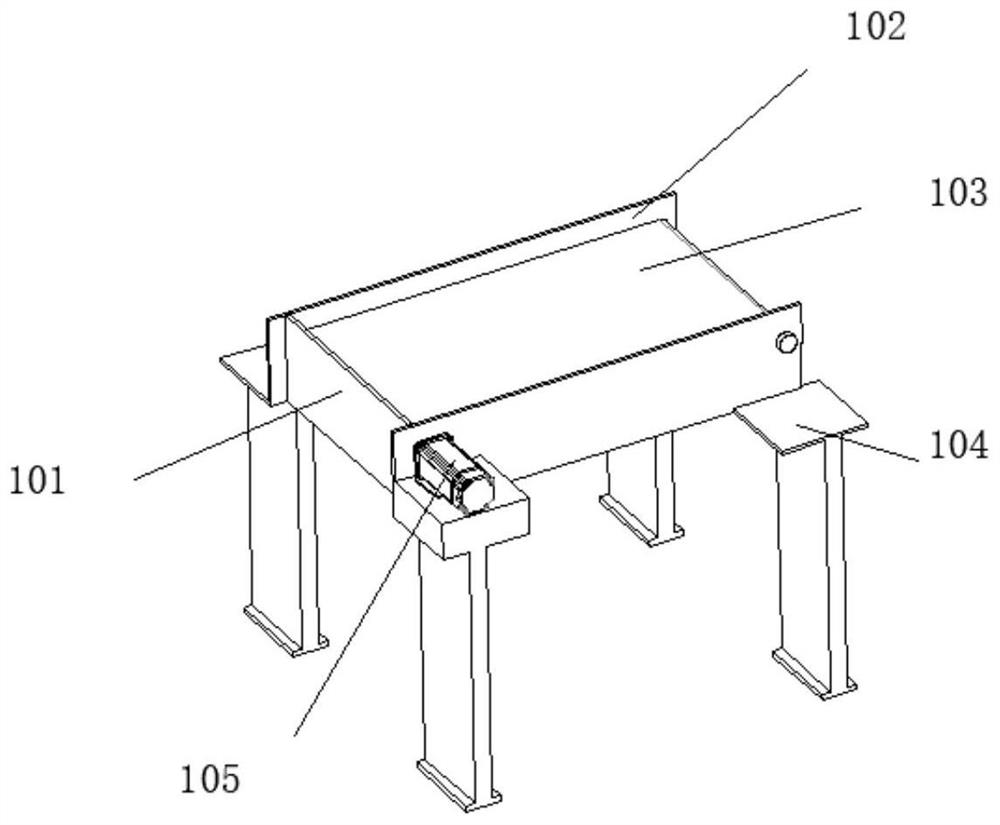

[0034] refer to figure 1 , a kneading air blowing integrated automatic feeding sunflower threshing machine, comprising a material preliminary conveying mechanism 100, a position adjustment differential belt mechanism 200, a material sorting slide rail platform 300, a material turning conveyor belt mechanism 400 and a threshing bin 500.

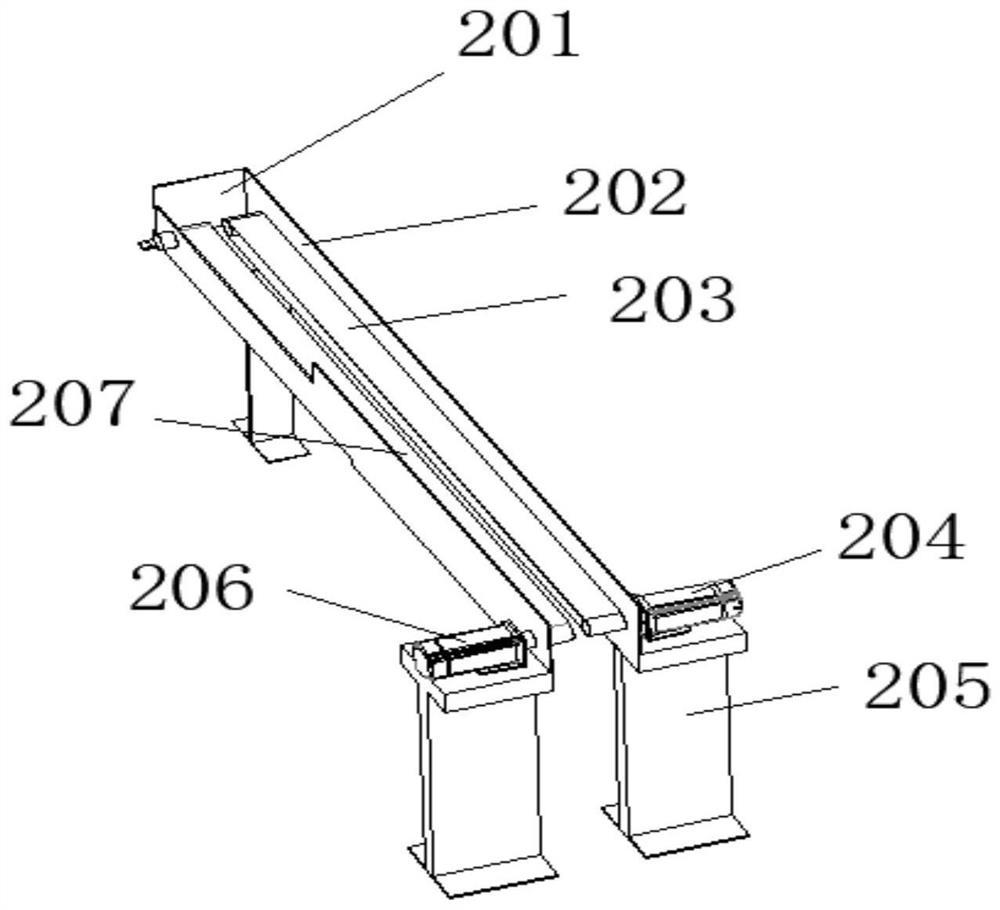

[0035] refer to image 3 , the posture adjustment differential belt mechanism 200 includes a synchronous belt transmission mechanism 1 203 and a synchronous belt transmission mechanism 2 207; the input ends of the synchronous belt transmission mechanism 1 203 and the synchronous belt transmission mechanism 2 207 are located at the output end of the material primary conveying mechanism 100 place; synchronous belt transmission mechanism one 203 and synchronous belt transmission mechanism two 207 have different rotating speeds, and turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com