Metal powder separation device and using method thereof

A metal powder and separation device technology, which is applied in the field of metal powder separation devices and metal powder separation devices, can solve the problems of not removing metal powder metal powder well, unfavorable work efficiency, and long time, so as to facilitate popularization , simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

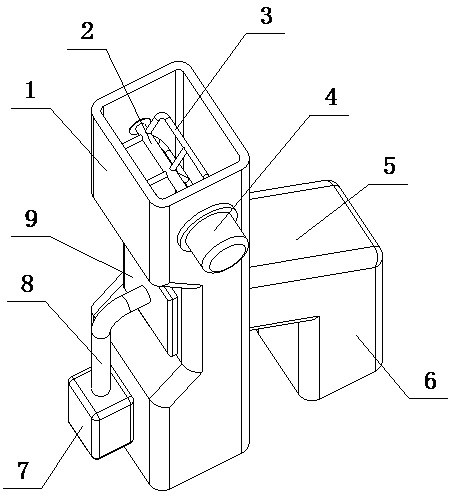

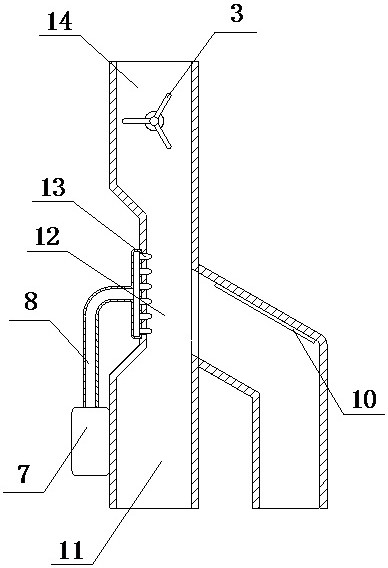

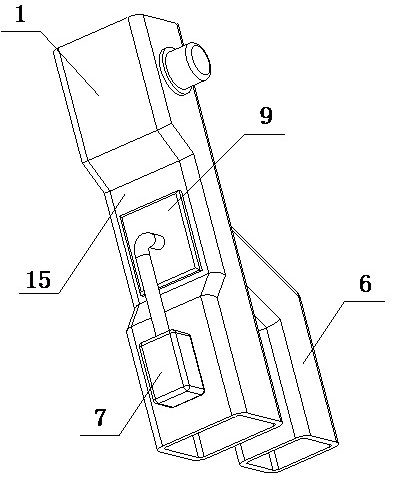

[0046] A metal powder separation device of the present invention is realized in the following way: a metal powder separation device of the present invention includes a feeding cylinder (1), a separation assembly placed on one side of the feeding cylinder (1) and a separation assembly placed on the feeding cylinder the discharge assembly on the other side of the body (1),

[0047] It is characterized in that the separation component separates the metal powder in the delivery cylinder (1), and the separated metal powder is discharged through the discharge component.

[0048] The feeding cylinder (1) is a long cylindrical structure with openings at both ends,

[0049]The feeding cylinder (1) is divided into three parts, the part near one end of the feeding cylinder (1) is the feeding chamber (14), and the middle part of the feeding cylinder (1) is the separation chamber (12) , the part near the other end of the feeding cylinder (1) is the discharge chamber (11), the feed chamber...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that an extension plate (16) is disposed at the entrance of the separation chamber (12), one end of the extension plate (16) is connected to the inner wall of one side of the separation chamber (12), and the other end is inclined Extending downward for a certain distance, the angle between the extension plate (16) and the inner wall of one side of the separation chamber (12) is an acute angle; when in use, it can guide the metal powder so that the metal powder is close to the separation output pipe (5 ), so that the airflow blows the metal powder into the separation output pipe (5);

Embodiment 3

[0064] The difference between this embodiment and Embodiment 2 is that there are multiple groups of leakage holes (17) equidistant on the extension plate (16); when in use, the metal powder falling into the separation chamber (12) can be horizontally Layering in the direction facilitates the separation of metal powder by air flow;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com