Method for finely adjusting fixing frame of pre-buried large overweight bolt sleeve group

The technology of bolt sleeve and fixing frame is applied in the field of fine-tuning of pre-embedded large-scale overweight bolt-sleeve group fixing frame, which can solve the problems of destroying the stress system of steel bars, time-consuming fine-tuning method, hidden safety hazards, etc., so as to achieve convenient production and save labor costs. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

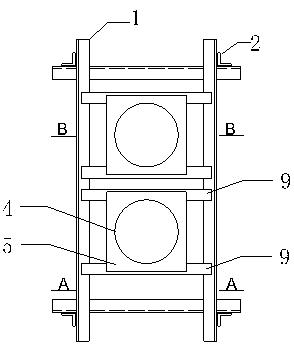

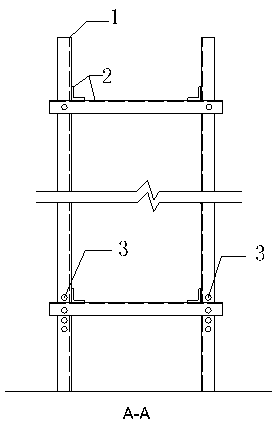

[0027] see now figure 2 with figure 2 , figure 2 for figure 1 The sectional view of A-A in, image 3 for figure 1 Sectional view of B-B in middle.

[0028] The fine-tuning method of the pre-embedded large overweight bolt sleeve group fixing frame of the present invention, the bolt sleeve group fixing frame includes a fixed bracket and a movable fixed frame, the fixing bracket is a box-shaped double-barrel structure, and four vertical poles are provided, and the vertical poles are channel steel 1. The channel steel is provided with a number of bolt holes 3 from bottom to top, so that the screw rod or fixing steel bar can penetrate through the holes when fixing later. The fine-tuning method of the pre-embedded large super-heavy bolt sleeve group fixing frame of the present invention comprises the following steps:

[0029] see now image 3 with Figure 4 , image 3 for figure 1 The sectional view of A-A in, Figure 4 for figure 1 Sectional view of B-B in middle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com