Ice sculpture forming mold and method for manufacturing ice sculpture

A technology for forming molds and ice sculptures, applied in the field of ice sculpture forming molds and making ice sculptures, can solve the problems of unfriendly ice sculpture artists, higher requirements for production skills, unreasonable mold structure, etc., and achieves low requirements for ice sculpture experience, simple production methods, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in detail below in conjunction with specific examples.

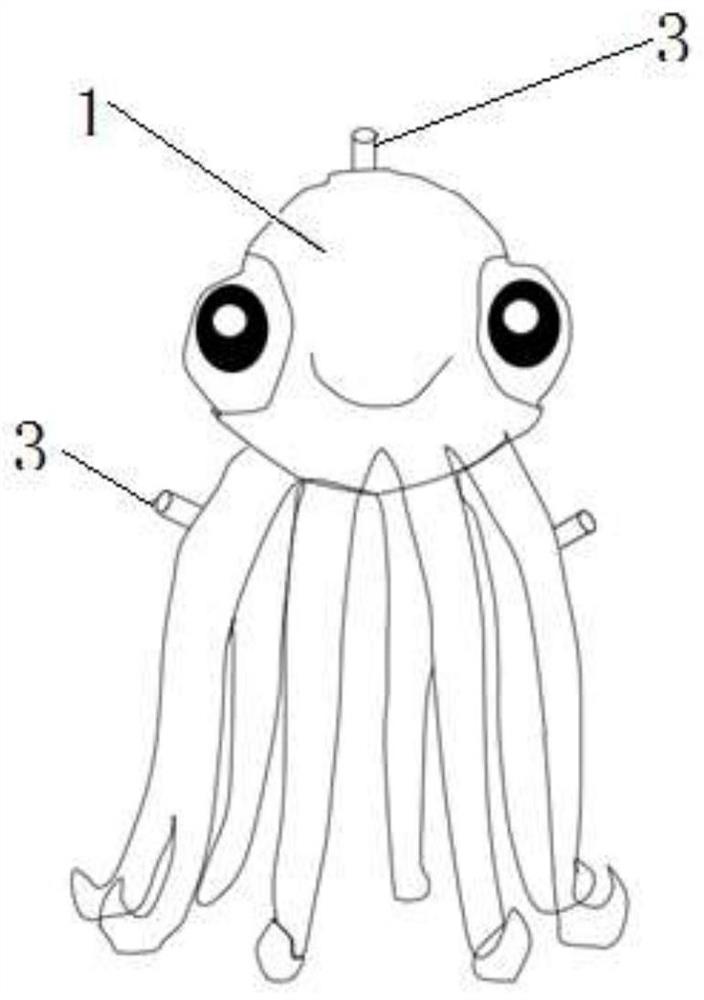

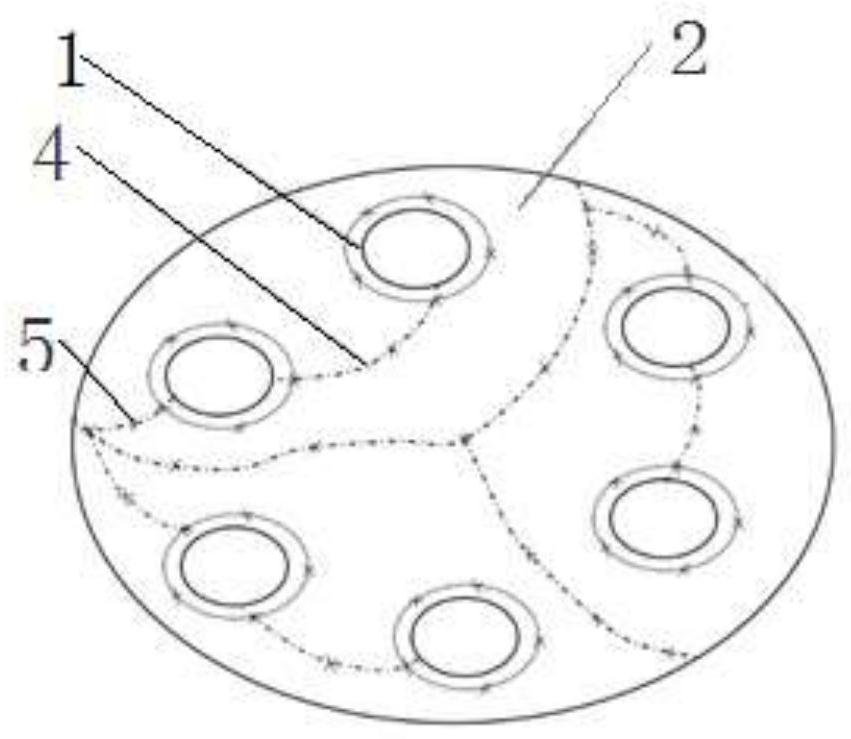

[0024] Such as Figure 1 ~ Figure 2 As shown, the present invention provides an ice sculpture molding mold, including a removable seal 1 with a hollow inner cavity and a detachable shape constraint 2 with a certain strength. The seal 1 has a channel 3 communicating with the inside and outside . Among them, the sealing element 1 is used for injecting the liquid to be solidified, and the shape constraint element 2 is used for shaping.

[0025] Wherein, the sealing member 1 is a deformable, liquid-impermeable membrane, which is a low-cost disposable product, preferably a film made of capsule-shaped plastic material, which is convenient for shaping the shape of the ice sculpture. After the ice sculpture is formed, Can be easily removed, such as cutting, tearing.

[0026] Further, at least one channel 3 is provided on the sealing member 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com