Preparation process of enzymolysis beef tallow

A preparation process and enzymatic hydrolysis technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of low enzymatic hydrolysis efficiency and rapid loss of nutritive components of butter, so as to improve the enzymatic hydrolysis effect, reduce the enzymatic hydrolysis time, The effect of strengthening the effect of refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

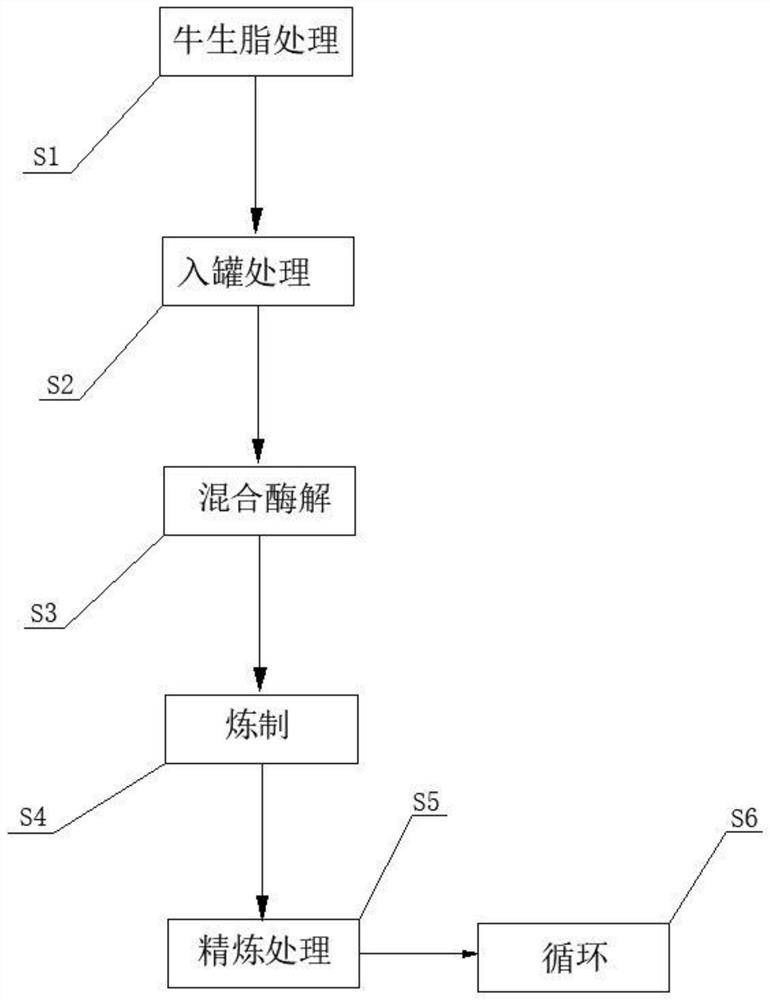

[0024] S1. Niu Sheng fat treatment, the bullying fats divided from the animal cattle body were grounded to obtain a small piece of fatty fat; S2. Into the tank treatment, pour the grease and liquid that have been grounded into the enzymatic solution In a tank, there is 0.5 copies of the stranded fat and liquid parts: 6 serviles, while the temperature of the tank is 45 ° C; S3. Mixed enzymatic hydrolysis, in the temperature stable fat, add content of 0.6%. Compoundase, continuous enzymatic solution to obtain primary enzymatic hydrolysis, S4. Refine, the primary enzymatic hydrazine fat solution is added to the smelting kettle to obtain a processed oil; S5. Refining treatment After the intermediate enzymatic hydrolysis is refined, an enzymatic hydrolyte is obtained by an enzymatic agglutination; S6. Circulating the S2-S5 step, the direct processing finished process ends.

[0025] Among them, the step S1 is specifically: the bulk fat is cut into a small piece, a bulk size of 1 mm × 1 ...

Embodiment 2

[0027] S1. Niu Sheng fat treatment, the bullying fats divided from the animal cattle body were grounded to obtain a small piece of fatty fat; S2. Into the tank treatment, pour the grease and liquid that have been grounded into the enzymatic solution In a tank, there is 1 part ratio of stranded fat and liquid parts: 7 serviles, and the temperature of the tank is 50 ° C; S3. Mixed enzymatic hydrolysis, in the temperature stable fat, add content of 0.8% The compound enzyme, continuous enzymatic hydrolysis, resulting in primary enzymatic hydrolysis, s4. Refine, the primary enzymatic hydrazine fat solution is added to the smelting kettle to obtain a process refining, to obtain a intermediate enzymatic hydrazine fat liquid; S5. Refining treatment After the intermediate enzymatic hydrolysis is refined, an enzymatic hydrolyte is obtained by an enzymatic agglutination; S6. Circulating the S2-S5 step, the direct processing finished process ends.

[0028] Among them, the step S1 is specifica...

Embodiment 3

[0030] S1. Niu Sheng fat treatment, the bullying fats divided from the animal cattle body were grounded to obtain a small piece of fatty fat; S2. Into the tank treatment, pour the grease and liquid that have been grounded into the enzymatic solution In a tank, there is 1 part ratio of stranded fat and liquid parts: 8 serviles, and the temperature of the tank is 50 degrees Celsius; S3. Mixed enzymatic hydrolysis, in the temperature stable fat, add content of 1.0% Compoundase, continuous enzymatic solution to obtain primary enzymatic hydrolysis, S4. Refine, the primary enzymatic hydrazine fat solution is added to the smelting kettle to obtain a processed oil; S5. Refining treatment After the intermediate enzymatic hydrolysis is refined, an enzymatic hydrolyte is obtained by an enzymatic agglutination; S6. Circulating the S2-S5 step, the direct processing finished process ends.

[0031] Wherein, the step S1 is specifically: the bulldone is cut into a small piece, a bulk size of 1 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com