Fragment material deironing device for aluminum product recovery processing

A technology for recycling and processing aluminum products, which is applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems that the quality of iron removal needs to be improved, and achieve the effects of novel structure, improved purity, and improved quality of iron removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

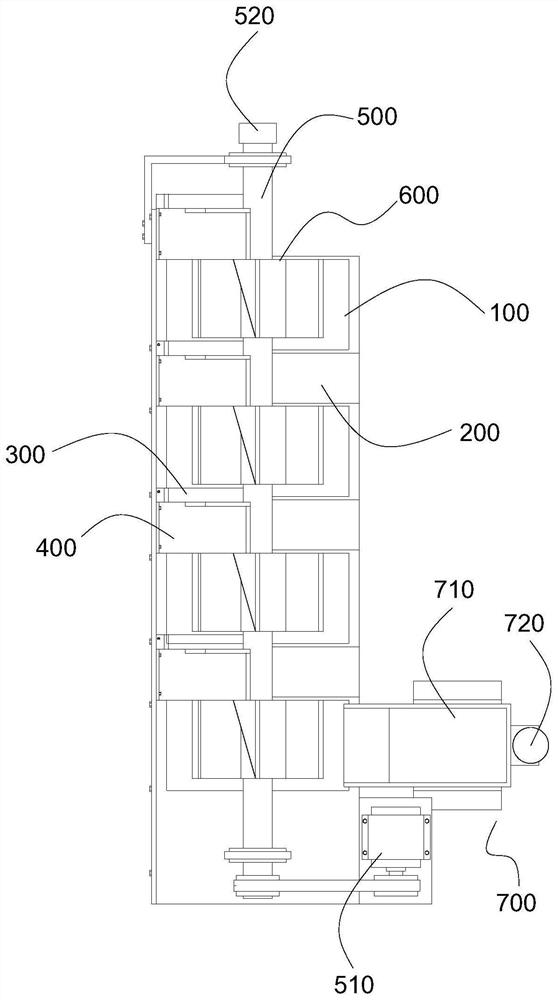

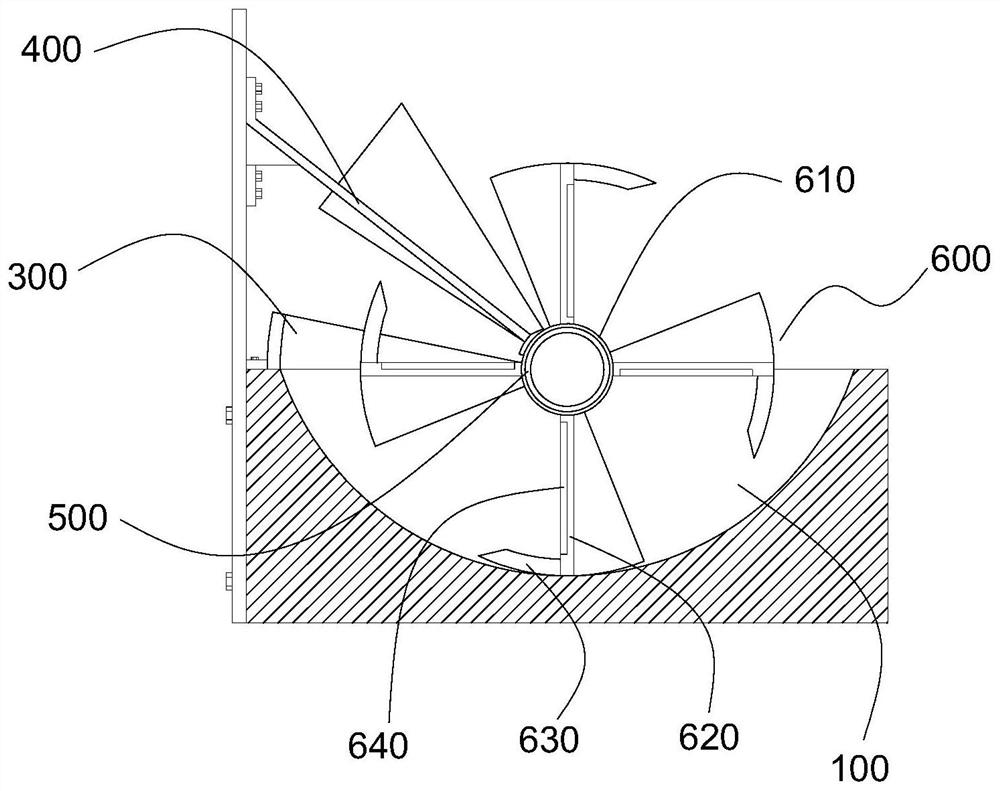

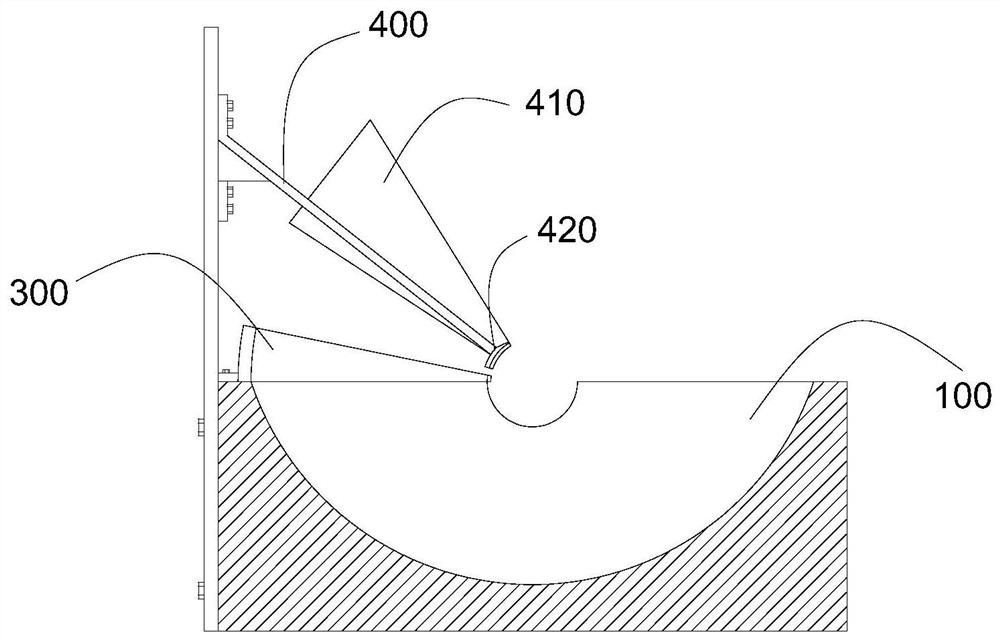

[0022] Such as Figure 1 to Figure 3 As shown, a specific embodiment of the present invention discloses a scrap material iron removal device for recycling aluminum products, including a plurality of troughs 100 arranged at intervals, and a discharge trough is left between two adjacent troughs 100 200, wherein the material trough is used to accept broken pieces, and the discharge chute is used to accept the separated iron fragments; the top of the discharge chute 200 is provided with a first material guide plate 300 and a second material guide plate 400, The second material guide plate 400 is located above the first material guide plate 300, the first material guide plate 300 and the second material guide plate 400 are inclined downward in the same direction, and the width of the first material guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com