Fly ash washing process for multistage reverse pulping

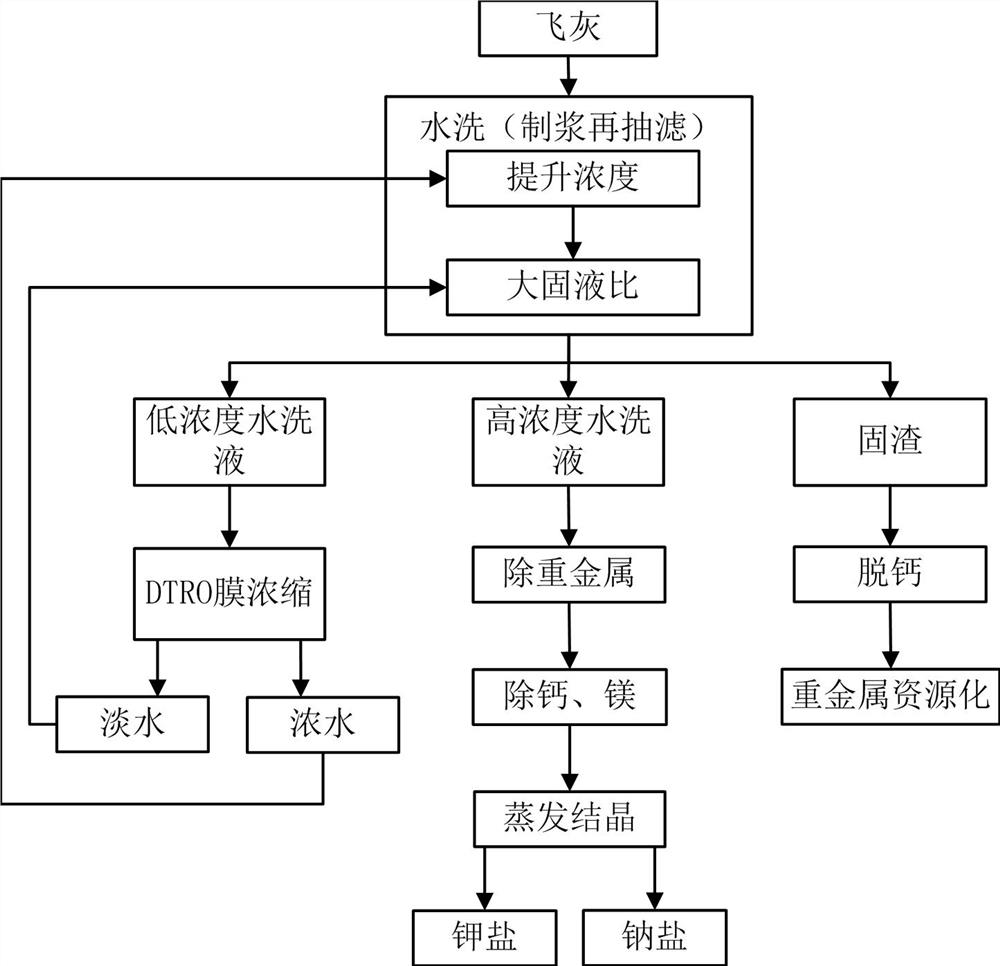

A technology for pulping and fly ash, which is applied in the field of fly ash water washing process of multi-stage reverse pulping, can solve the problem that the soluble salt of washing liquid cannot be effectively used, and achieve the effects of low cost, saving water consumption and improving washing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

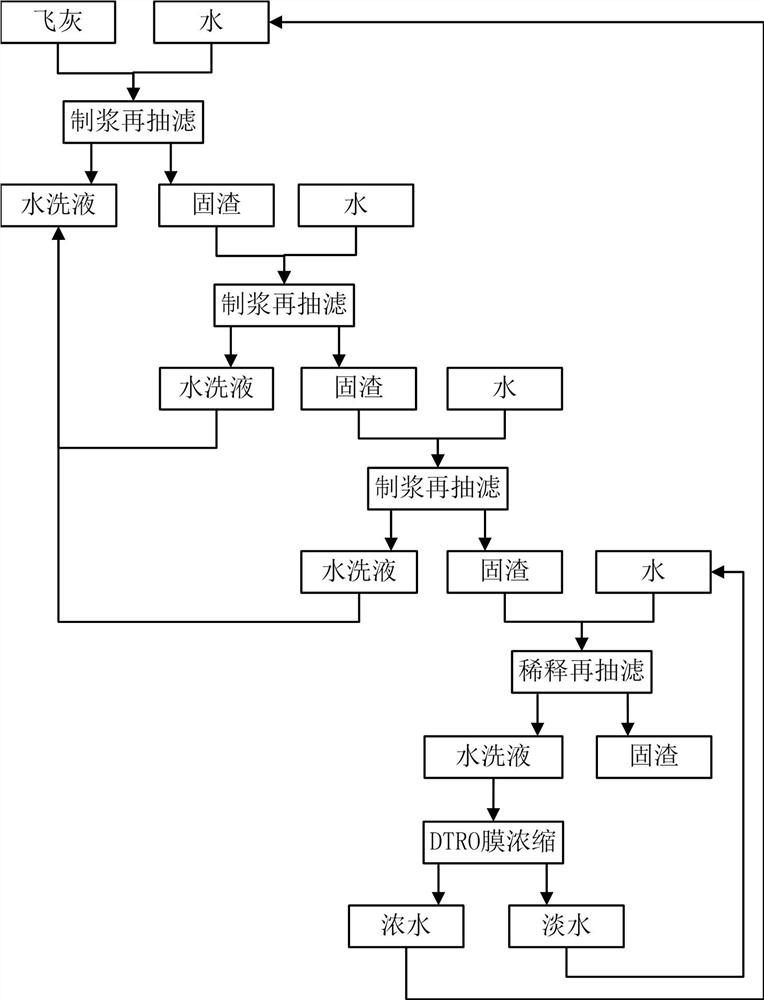

[0027] Example 1, such as figure 2 As shown, it includes the following steps:

[0028] Step 1. Mix and stir the fly ash and water according to the solid-to-liquid ratio of 1:3 to make slurry;

[0029] Step 2, using a suction filter to suction filter the pulping product in step 1 to achieve solid-liquid separation to obtain washing liquid and solid residue;

[0030] Step 3, mixing and stirring the solid slag obtained in the previous step 2 and water according to a solid-to-liquid ratio of 1:3;

[0031] Step 4, using a suction filter to filter the pulping product in step 3 to achieve solid-liquid separation, to obtain washing liquid and solid residue, and mixing the washing liquid with the washing liquid obtained in step 2;

[0032] Step 5, mixing and stirring the solid slag obtained in the previous step 4 and water according to the solid-to-liquid ratio of 1:3;

[0033] Step 6, use a suction filter to filter the pulping product in step 5 to achieve solid-liquid separation, ...

Embodiment 2

[0036] Example 2, such as figure 2 As shown, it includes the following steps:

[0037]Step 1. Mix and stir the fly ash and water according to the solid-to-liquid ratio of 1:4 to make slurry;

[0038] Step 2, using a suction filter to suction filter the pulping product in step 1 to achieve solid-liquid separation to obtain washing liquid and solid residue;

[0039] Step 3, mixing and stirring the solid slag obtained in the previous step 2 and water according to the solid-to-liquid ratio of 1:4;

[0040] Step 4, using a suction filter to filter the pulping product in step 3 to achieve solid-liquid separation, to obtain washing liquid and solid residue, and mixing the washing liquid with the washing liquid obtained in step 2;

[0041] Step 5, mixing and stirring the solid slag obtained in the previous step 4 and water according to the solid-to-liquid ratio of 1:4;

[0042] Step 6, use a suction filter to filter the pulping product in step 5 to achieve solid-liquid separation,...

Embodiment 3

[0045] Embodiment 3, it comprises the steps:

[0046] Step 1. Mix and stir the fly ash and water according to the solid-to-liquid ratio of 1:5 to make slurry;

[0047] Step 2, using a suction filter to suction filter the pulping product in step 1 to achieve solid-liquid separation to obtain washing liquid and solid residue;

[0048] Step 3, mixing and stirring the solid slag obtained in the previous step 2 and water according to the solid-to-liquid ratio of 1:5;

[0049] Step 4, using a suction filter to filter the pulping product in step 3 to achieve solid-liquid separation, to obtain washing liquid and solid residue, and mixing the washing liquid with the washing liquid obtained in step 2;

[0050] Step 5, mixing and stirring the solid slag obtained in the previous step 4 and water according to the solid-to-liquid ratio of 1:5;

[0051] Step 6, use a suction filter to filter the pulping product in step 5 to achieve solid-liquid separation, obtain washing liquid and solid r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com