Bionic leaf model and preparation method and application thereof

A technology of leaves and models, which is applied in the field of microfluidic chip production, can solve problems such as environmental damage, affecting chip production, and affecting experiment progress, and achieves good shape retention and long-term storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

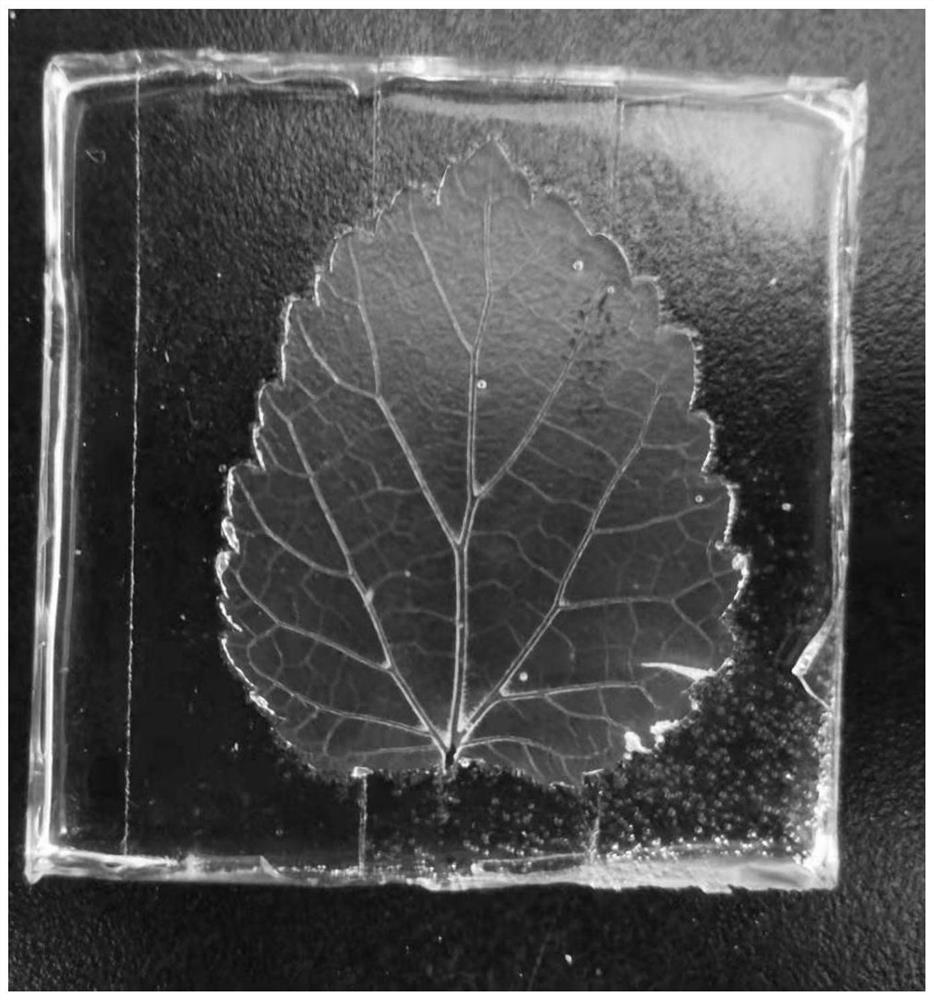

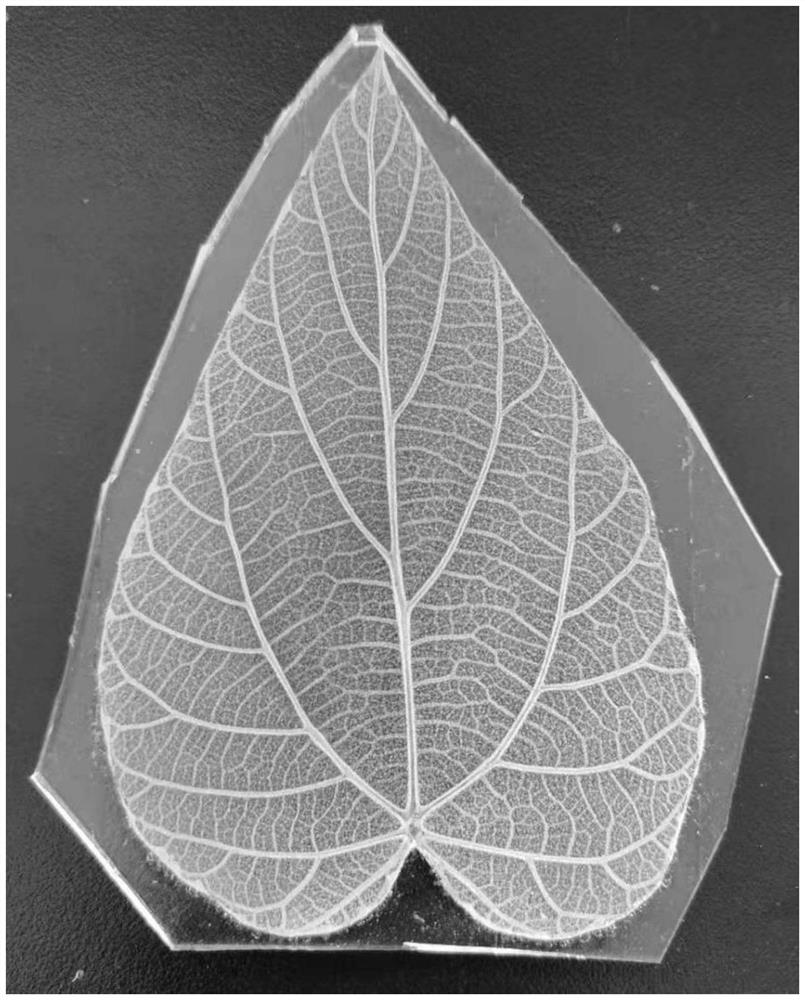

Image

Examples

Embodiment 1

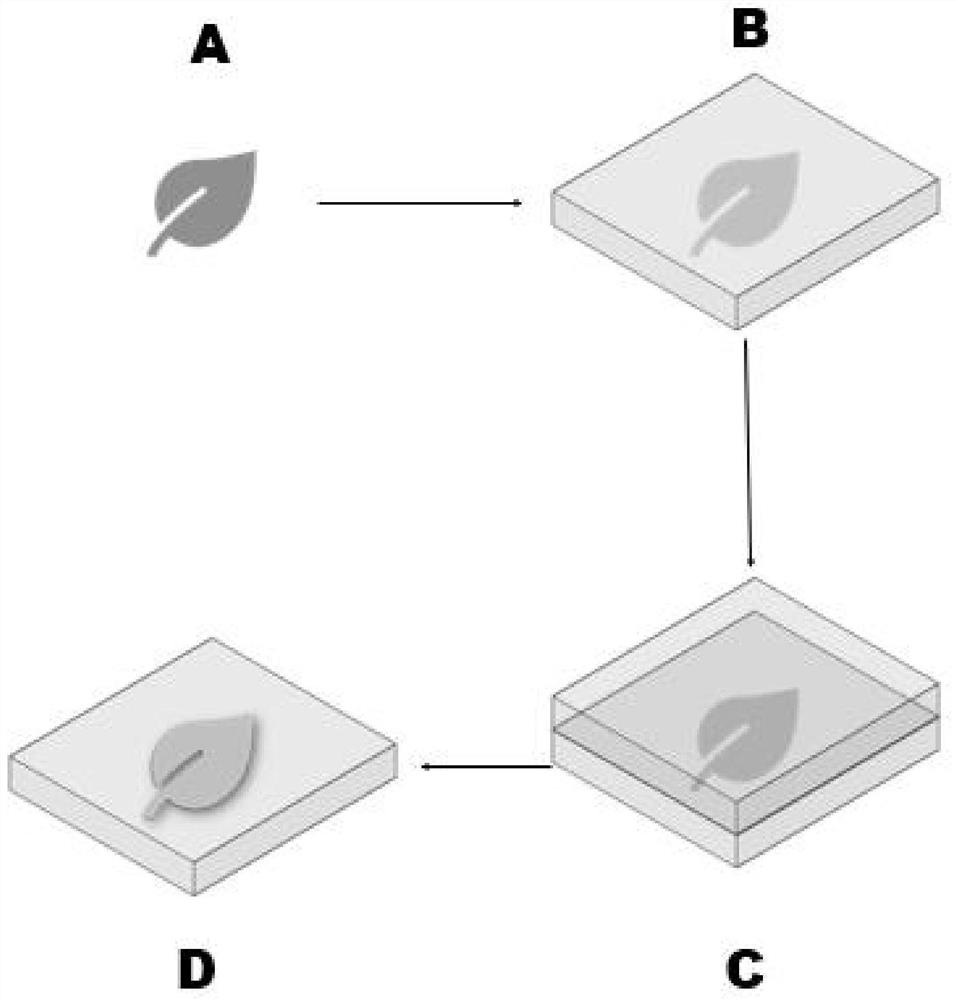

[0051] A method for preparing a bionic leaf model capable of making a microfluidic chip without seasonal restrictions, comprising the following steps:

[0052] S1, fresh leaves processing

[0053] Boil the picked fresh leaves in 75% ethanol solution for disinfection, take them out after a period of time, and dry them with filter paper;

[0054] S2, PDMS polymer configuration

[0055] The PDMS polymer is mixed according to the mass ratio of glue A: glue B = 10:1. The models of glue A and glue B are Momentive RTV615.

[0056] S3. Preparation of negative mold of bionic leaf model

[0057] Use the back of the leaf as the positive mold, stick the double-sided adhesive on the glass plate, stick the front of the leaf on the double-sided tape, cover the surface of the positive mold with a layer of PDMS polymer, and completely remove the air bubbles in a vacuum drying oven for 20 minutes. Make sure that the mixed solution is polymerized in a closed environment to form a hydrogel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com