Yellowing-resistant UV-LED curable coating material composition

A UV-LED and composition technology, applied in polyester coatings, polyether coatings, epoxy resin coatings, etc., can solve the problems of single wavelength of curing light source, application limitation, and low surface strength of paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

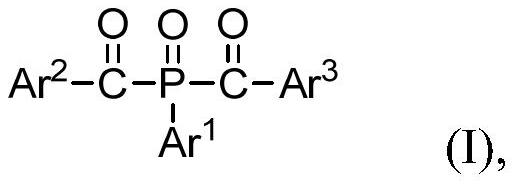

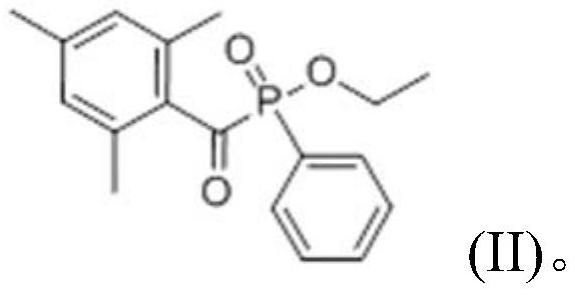

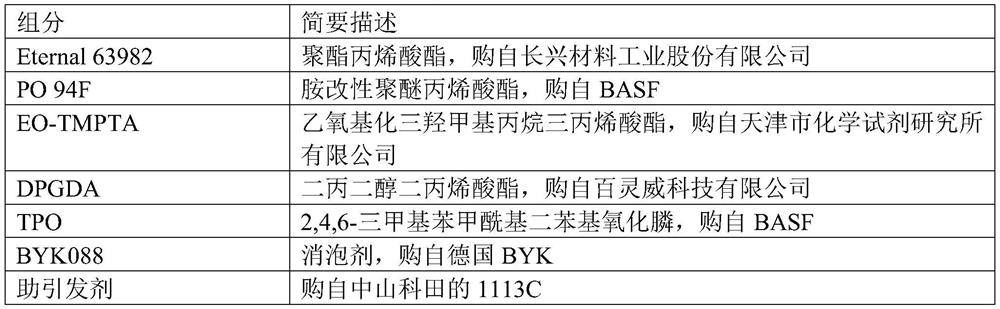

Method used

Image

Examples

Embodiment

[0105] Test Methods

[0106] Attachment

[0107] Adhesion test performed to evaluate the coated substrate for coating adhesion. Adhesion tests were conducted according to the test method ASTMD 3359- B. Adhesion is generally rated on a scale 0-5B where 5B indicates optimal adhesion.

[0108] Gloss

[0109] The test used to measure the gloss of the cured coating. According to ASTM D523 using a small Kongguang Ze Sheen Instrument 60 ° gloss was evaluated.

[0110] Characterization of yellow resistance

[0111] BYK white test card in paper coating, blade coating may be UV-LED-curable coating composition, coating amount of 10-12g / m 2 ; At 395nm LED-UV light curing, curing energy 1000-1500mJ / cm 2 ; After curing is complete, and is calculated using the color difference meter test (the following formula) with the original color value of a white area coated paper jam.

[0112] △ E = [(△ L *) 2 + (△ a *) 2 + (△ b *) 2 ] 1 / 2

[0113]Among them, ΔL = l sample -L standard (difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com