Method for repairing abandoned mine by using titanium gypsum as impermeable lining

A technology of titanium gypsum and anti-seepage layer, which is applied in the field of repairing abandoned mines using titanium gypsum as an anti-seepage lining, can solve the problems of non-conformity with solid waste recycling, high landfill disposal costs, and limited disposal destinations, and achieve the goal of promoting The effect of improving the development and social green concept, improving the quality of the ecological environment, and saving disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The above-mentioned content of the present invention will be described in further detail below by the form of the embodiment, but this should not be interpreted as the scope of the above-mentioned theme of the present invention being limited to the following embodiments, all technologies realized based on the above-mentioned content of the present invention belong to scope of the invention.

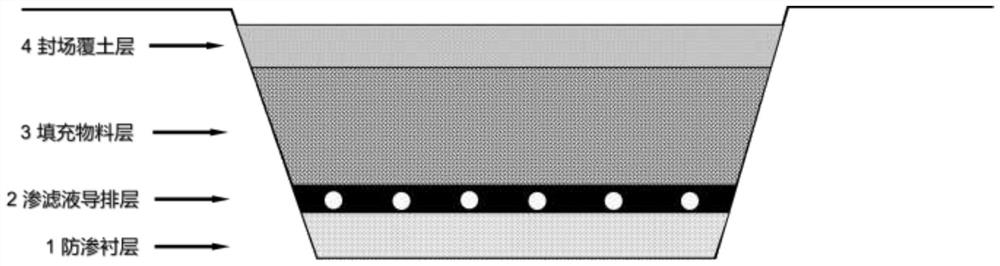

[0027] Such as figure 1 As shown, according to a method for repairing an abandoned mine using titanium gypsum as an anti-seepage lining according to an embodiment of the present invention, the anti-seepage lining 1, the leachate drainage layer 2, and the filling material layer 3 are sequentially arranged from bottom to top. 4. Closing soil layer 4. The titanium gypsum in the anti-seepage lining 1 comes from a titanium dioxide production enterprise in Anhui, which is representative of the industry. Titanium gypsum is made of titanium concentrate (main component TiO2≥46%) through "...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com