Compression roller adjusting mechanism of calender

A technology of adjusting mechanism and calender, which is applied in the directions of dough sheeter/roller/rolling pin, dough forming machinery or equipment, and baking, etc. The quality and taste of slices, the inability to achieve online control and other problems, to achieve the effect of enriching varieties, reducing production and processing procedures, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

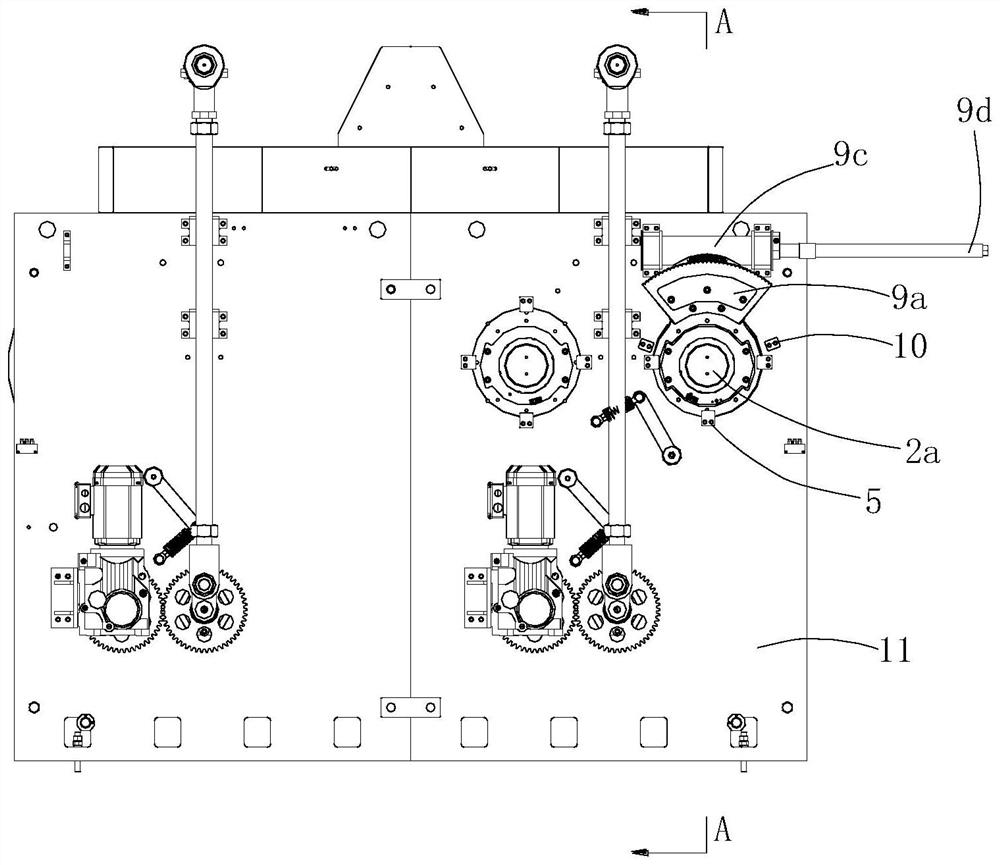

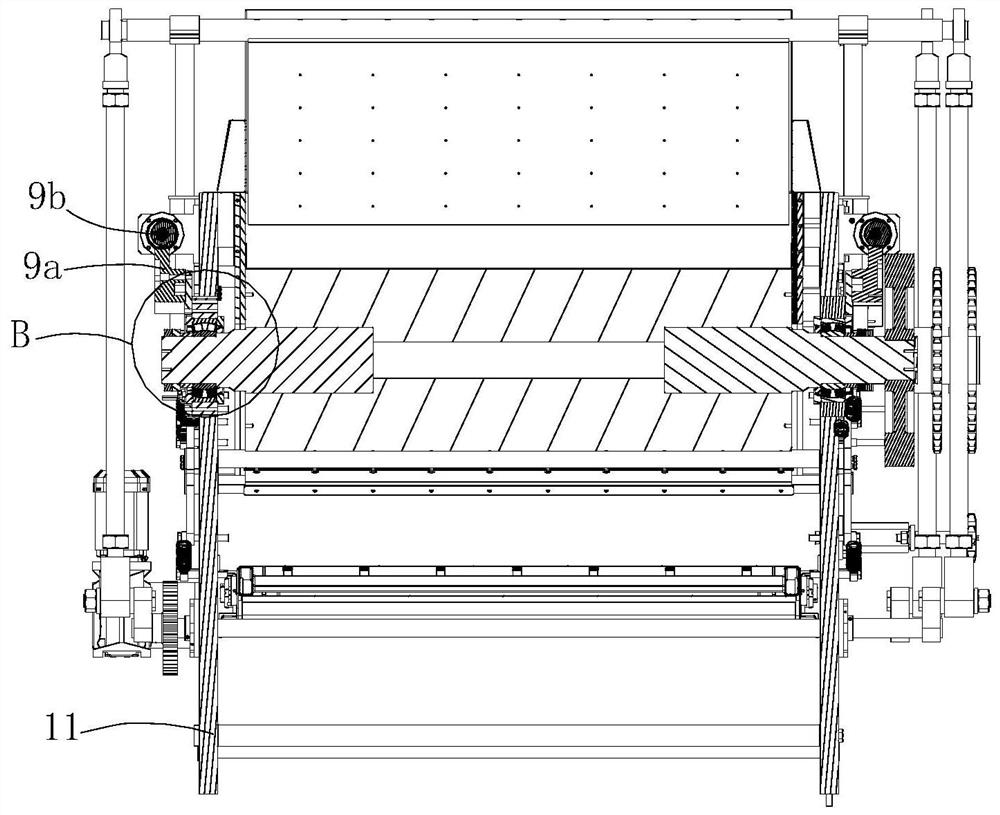

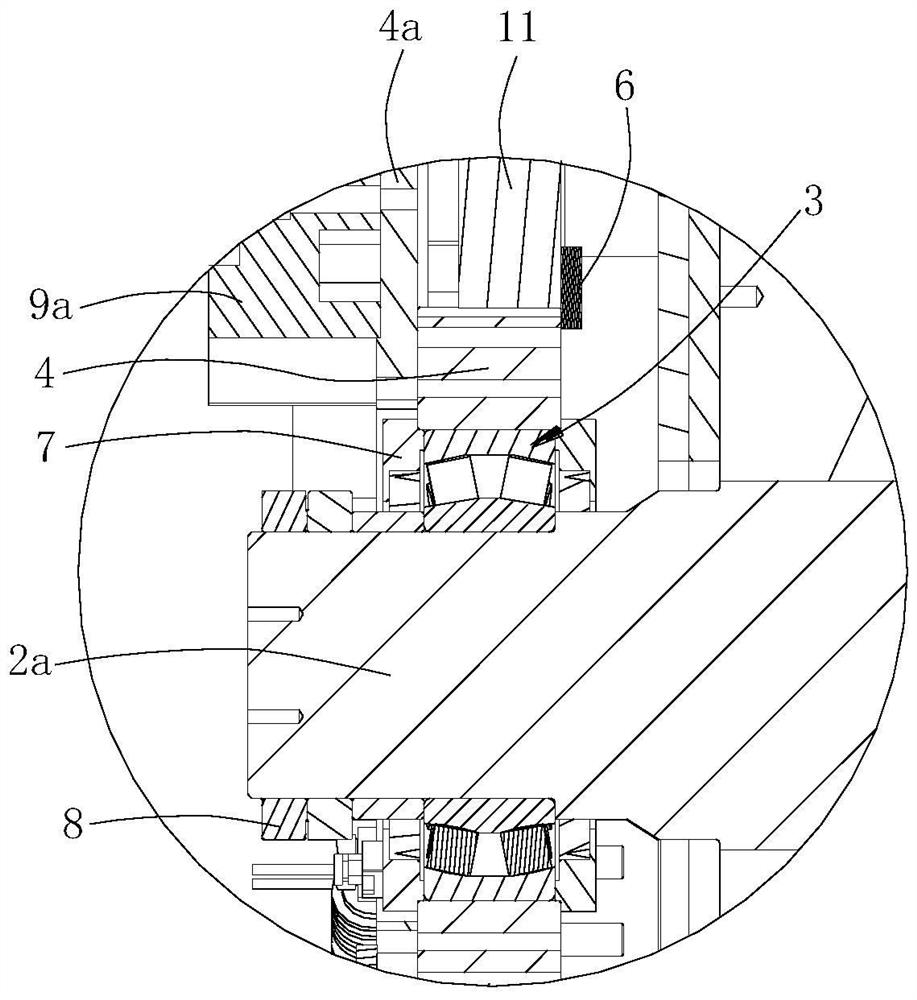

[0021] Such as Figures 1 to 4 shown

[0022] The pressure roller adjustment mechanism includes a driving pressure roller 1, a driven pressure roller 2, two eccentric sleeves 4 and two sets of worm gear assemblies.

[0023] The main parts of the driving roller 1 and the driven roller 2 are located inside the calender, and the two ends of the driving roller 1 and the driven roller 2 are respectively provided with supporting semi-shafts, and the driving roller 1 is supported on the calender through the supporting semi-shafts. On the frame 11, the active pressing roller 1 and the driven pressing roller 2 are arranged in parallel, and there is a calendering passage for the flour raw materials to pass between the driving pressing roller 1 and the driven pressing roller 2, and the driving pressing roller 1 and the driven pressing roller The rollers 2 are connected through a gear transmission mechanism.

[0024] The supporting semi-shafts 2a on both sides of the dynamic pressure ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com