Hot melting equipment for forming self-lubricating bearing metal part

A technology of self-lubricating bearings and metal parts, applied in metal processing equipment, machine tools suitable for grinding the edge of workpieces, welding equipment, etc., can solve problems such as hot melt parts burn workers, affect product quality, and cause danger in the splicing process. Achieve the effect of avoiding wasting a lot of time, improving convenience and saving loading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

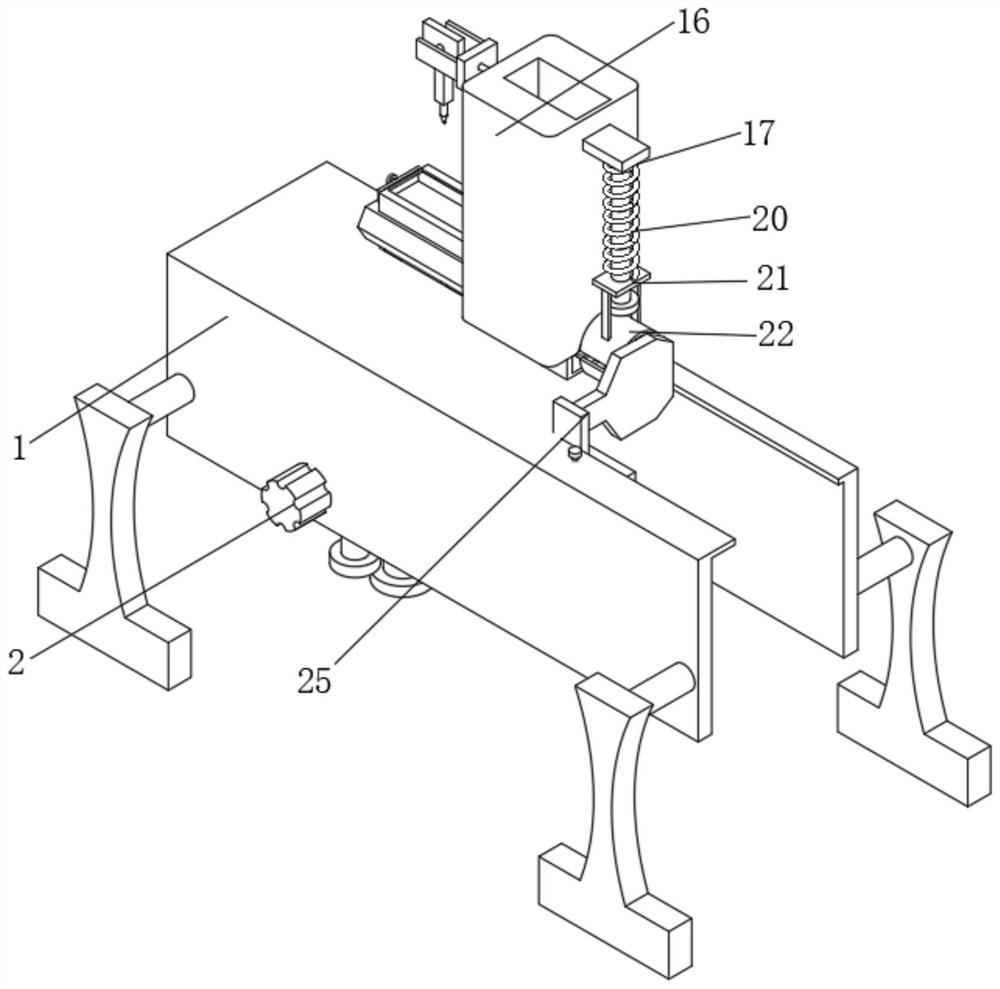

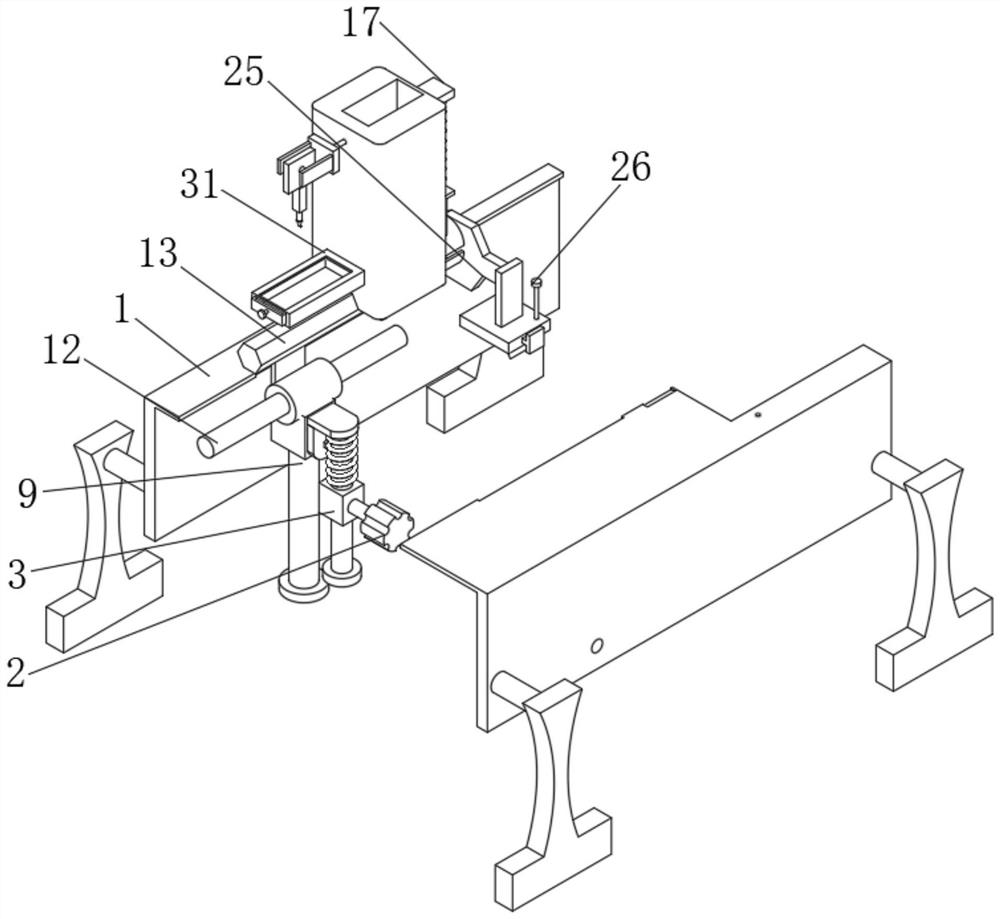

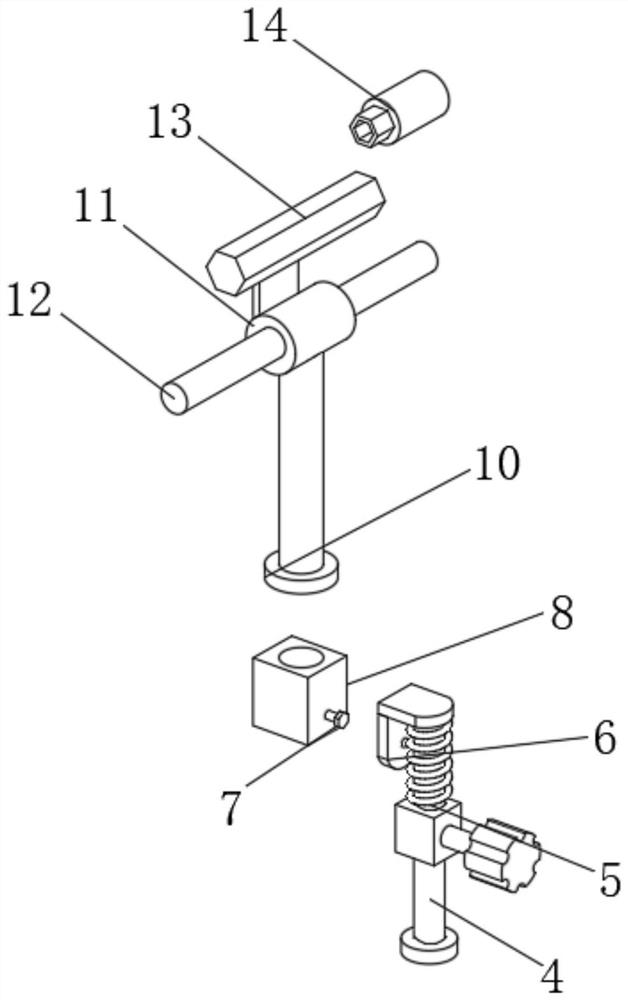

[0024] see figure 1 , figure 2 with image 3 , the present invention provides a technical solution: a hot-melt equipment for forming self-lubricating bearing metal parts, including a carrier 1, a servo motor 2 is fixedly installed on the left side of the front of the carrier 1, and the output shaft of the servo motor 2 is The first driving block 3 is fixedly sleeved, and the middle part of the first driving block 3 is provided with a driving groove. Block 6, a return spring 5 is arranged between the first drive block 3 and the fixed block 6. When the first drive block 3 drives the drive arm 4, the first drive block 3 will squeeze the return spring 5, so that Retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com