PVC coiled material printing machine

A printing machine and roll material technology, applied in the field of PVC roll material printing machines, can solve the problems of insufficient dust removal and strong odor, and achieve the effect of improving the dust removal effect and increasing the sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

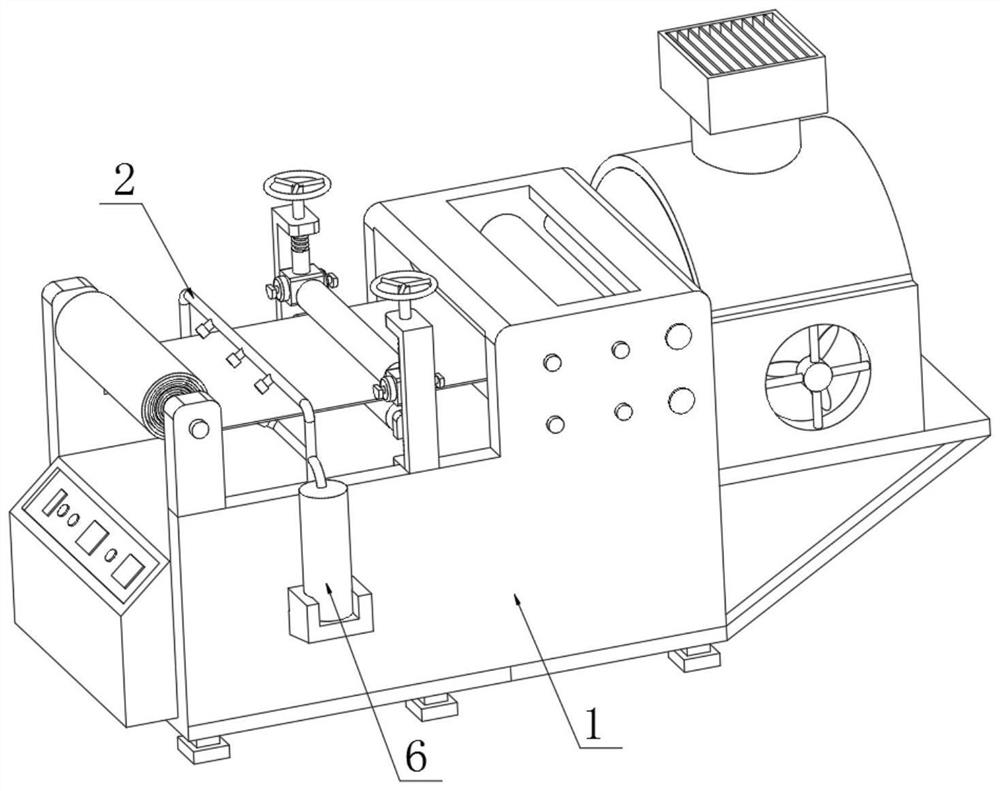

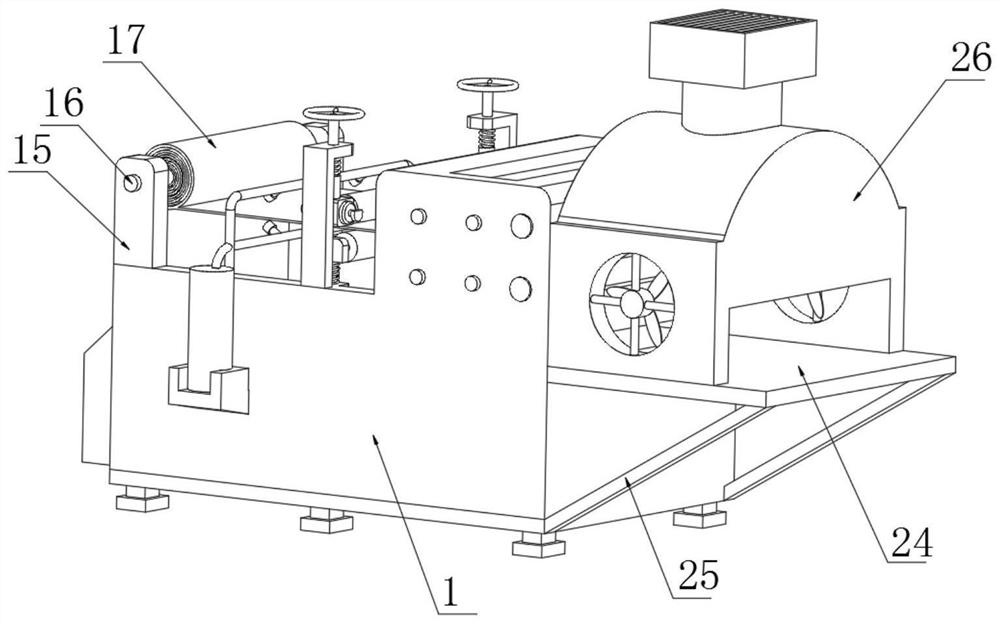

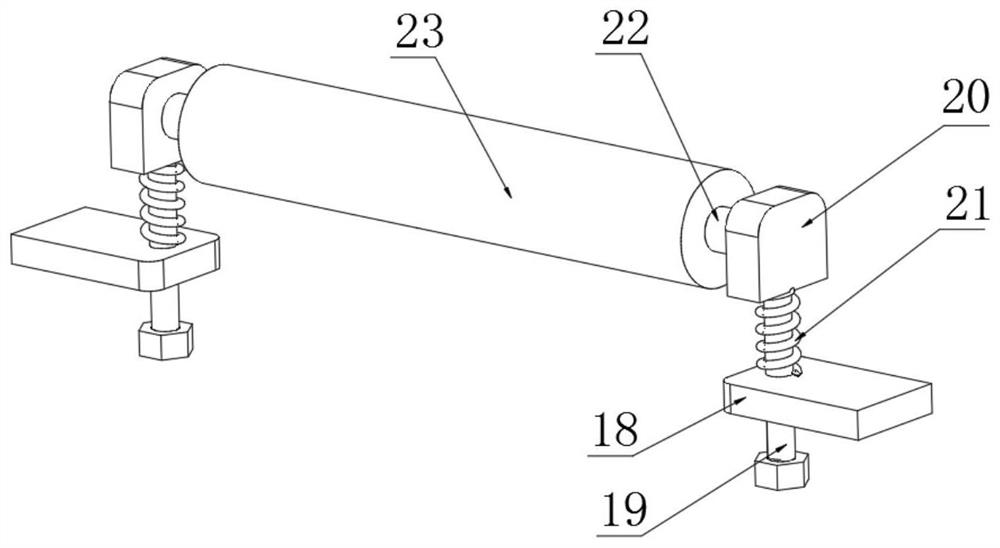

[0030] see Figure 1-8 , the present invention provides the following technical solutions: a PVC roll printing machine, including a body 1, the front of the body 1 is fixedly connected with a first conduit 2, one side of the outer surface of the first conduit 2 is plugged with a first nozzle 3, the second One side of the outer surface of a conduit 2 is inserted with a second conduit 4, and one side of the outer surface of the second conduit 4 is inserted with a second nozzle 5. The front of the body 1 is fixedly connected with an air pump 6, and the air pump 6 is connected to the first conduit 2. Phase conduction, one side of the upper surface of the body 1 is fixedly connected with a vertical plate 7, the upper surface of the vertical plate 7 is threaded with a threaded rod 8, the bottom end of the threaded rod 8 is sleeved with a sleeve 9, and the outer surface of the threaded rod 8 A first spring 10 is sleeved, one end of the first spring 10 is fixedly connected to the slee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap