A kind of preparation method of furniture cleaning and sterilization glazing aerosol

A phosgene and furniture technology, which is applied in the direction of paint containing biocide, liquid treatment, transportation and packaging, etc., can solve the problems of the glazing effect of the glazing aerosol is not long-lasting and the canning accuracy is inaccurate. Inaccurate installation accuracy, uniform material body, and the effect of improving stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

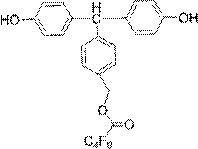

[0046] Fluorinated branched compounds are made by the following steps:

[0047] B1. Dissolve 0.1mol of p-hydroxymethylbenzaldehyde and 0.22mol of phenol in glacial acetic acid, cool to 0°C, add dropwise a mixture of 10mL of concentrated sulfuric acid with a mass fraction of 98% and 30mL of glacial acetic acid while stirring, drop After the addition, the reaction was continued at 0°C for 72 hours, then poured into frozen ice water, stirred for 1 hour, filtered, washed with water until the filtrate was neutral, and dried in vacuo to constant weight to obtain 4-hydroxymethyl-4',4'- Dihydroxytriphenylmethane;

[0048] B2. Add 0.12mol of 4-hydroxymethyl-4',4'-dihydroxytriphenylmethane, 100mL of glacial acetic acid, and 4mL of p-toluenesulfonic acid into a three-necked flask with a condensing reflux tube and a stirring magnet, and stir evenly. Use an oil bath to heat the temperature of the reaction system to 61°C. Under stirring, add 0.1 mol of perfluorovaleric acid dropwise with a...

Embodiment 2

[0050] Modified polyurethane resins are made through the following steps:

[0051] S1. Mix 2 mol of isophorone diisocyanate, 1 mol of polyester diol with a relative molecular weight of 1000 and 10 g of dibutyltin dilaurate evenly, and react in a water bath at 78° C. for 2 hours to obtain isocyanate group-terminated polyurethane;

[0052] S2. Under the protection of nitrogen, mix 0.1mol of isocyanate-terminated polyurethane, 2.3g of dibutyltin dilaurate and 70mL of glacial acetic acid, and slowly add 0.21mol of the mixture prepared in Example 1 at 93°C with a constant pressure dropping funnel. The glacial acetic acid solution of the fluorine-containing branched compound was 50mL, and the dropping rate was 2 drops / second. After the dropwise addition, the reaction was continued for 3h, flocculated with 100mL deionized water / methanol, and dried in a vacuum oven at 100°C for 24h to obtain Modified polyurethane.

Embodiment 3

[0054] Modified polyurethane resins are made through the following steps:

[0055] S1. Mix 2 mol of toluene diisocyanate, 1 mol of polyester diol with a relative molecular weight of 1200 and 18 g of dibutyltin dilaurate evenly, and react in a water bath at 78° C. for 2 hours to obtain isocyanate group-terminated polyurethane;

[0056] S2. Under the protection of nitrogen, mix 0.1 mol of isocyanate-terminated polyurethane, 1.8 g of dibutyltin dilaurate and 70 mL of glacial acetic acid, and slowly add 0.22 mol of the mixture prepared in Example 1 at 93°C with a constant pressure dropping funnel. The glacial acetic acid solution of the fluorine-containing branched compound was 50mL, and the dropping rate was 2 drops / second. After the dropwise addition, the reaction was continued for 3h, flocculated with 100mL deionized water / methanol, and dried in a vacuum oven at 100°C for 24h to obtain Modified polyurethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com