Bent cap structure adopting a double-main-beam prefabricating and assembling method and construction method thereof

A technology of prefabricated assembly and double main girders, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of mold expansion and deformation of prefabricated shell concrete, complex on-site construction, easy cracking, etc., to achieve fast construction speed and small construction workload , good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Concrete structure and construction method of the present invention are provided in detail by following embodiment and accompanying drawing thereof.

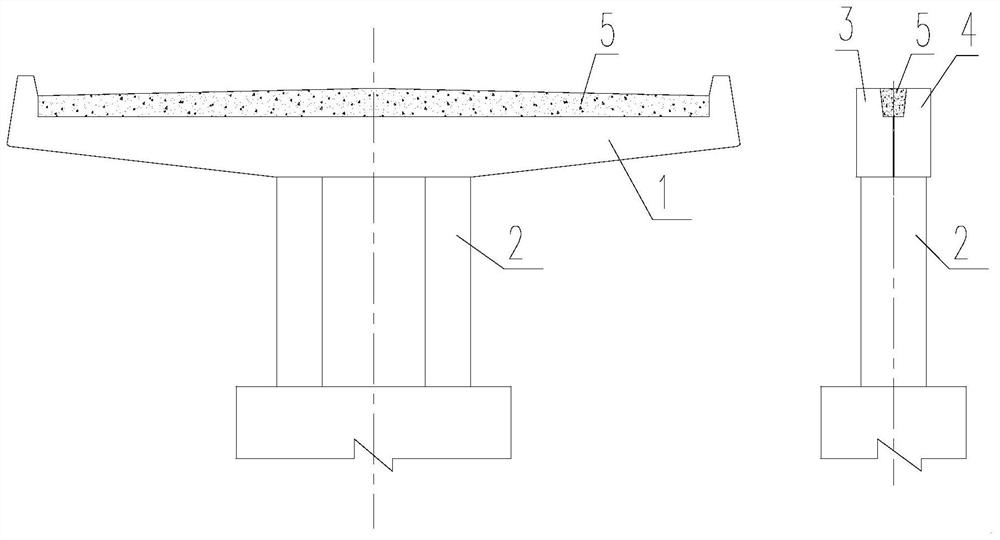

[0040] This embodiment adopts the cover beam structure of double main beam prefabrication and assembly method, as shown in the attached figure 1 ~4, combined with the accompanying drawings, the description is as follows:

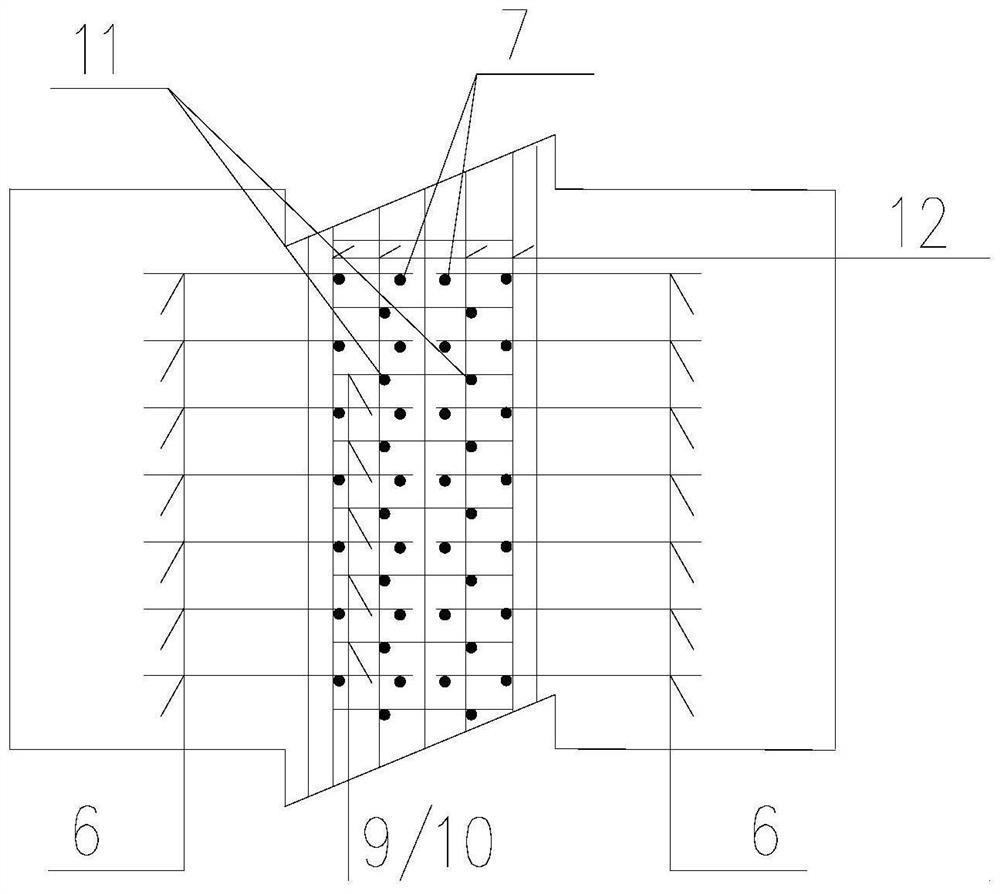

[0041] Such as figure 1 As shown, the cover beam 1 is installed on the top of the pier column 2. The cross section of the cover beam 1 is composed of the left precast section 3, the right precast section 4 and the middle trapezoidal post-cast section 5. The left precast section 3 and the right precast section Section 4 reserves a notch on the upper part, and forms a trapezoidal post-cast section connection structure after assembly.

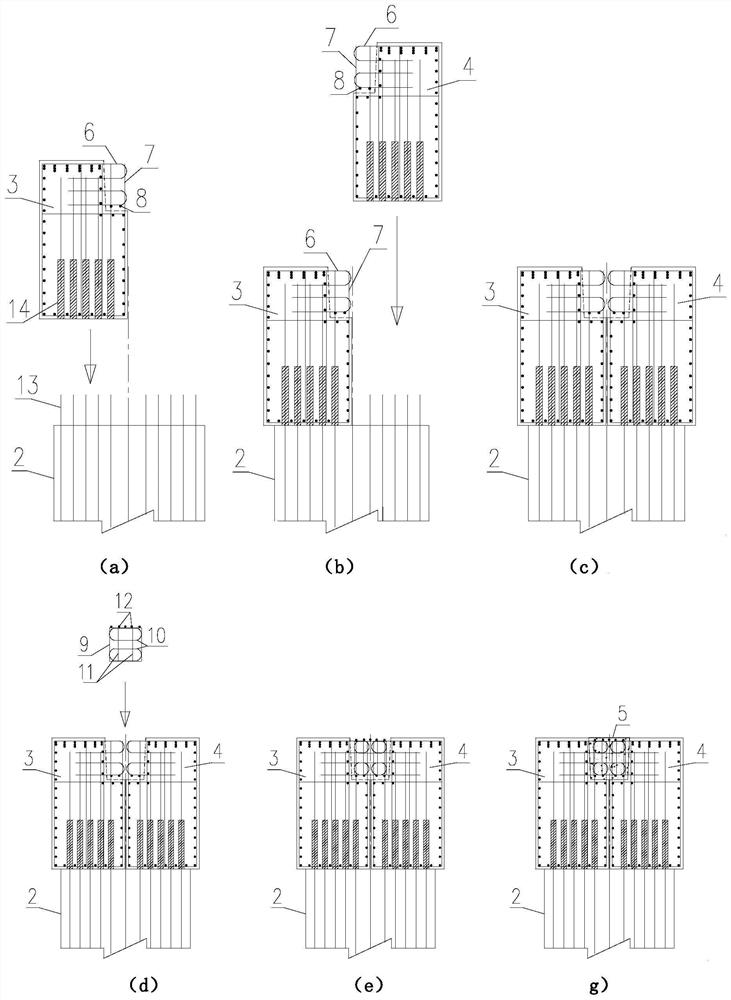

[0042] In this embodiment, the construction steps of the cover beam structure using the double main beam prefabricated assembly method are as follows:

[0043] 1. Prefab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com