Aluminum alloy wall for building decoration

An aluminum alloy and wall technology, which is applied to buildings, building components, building structures, etc., can solve the problems of affecting the use effect of the wall, easily deforming, time-consuming and labor-intensive, etc., so as to achieve convenient and quick installation, improve the use effect, reduce the The effect of deformation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

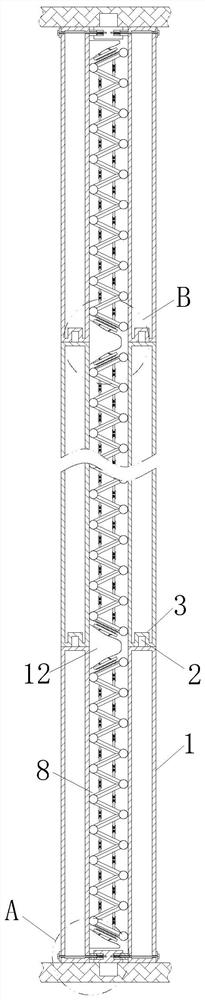

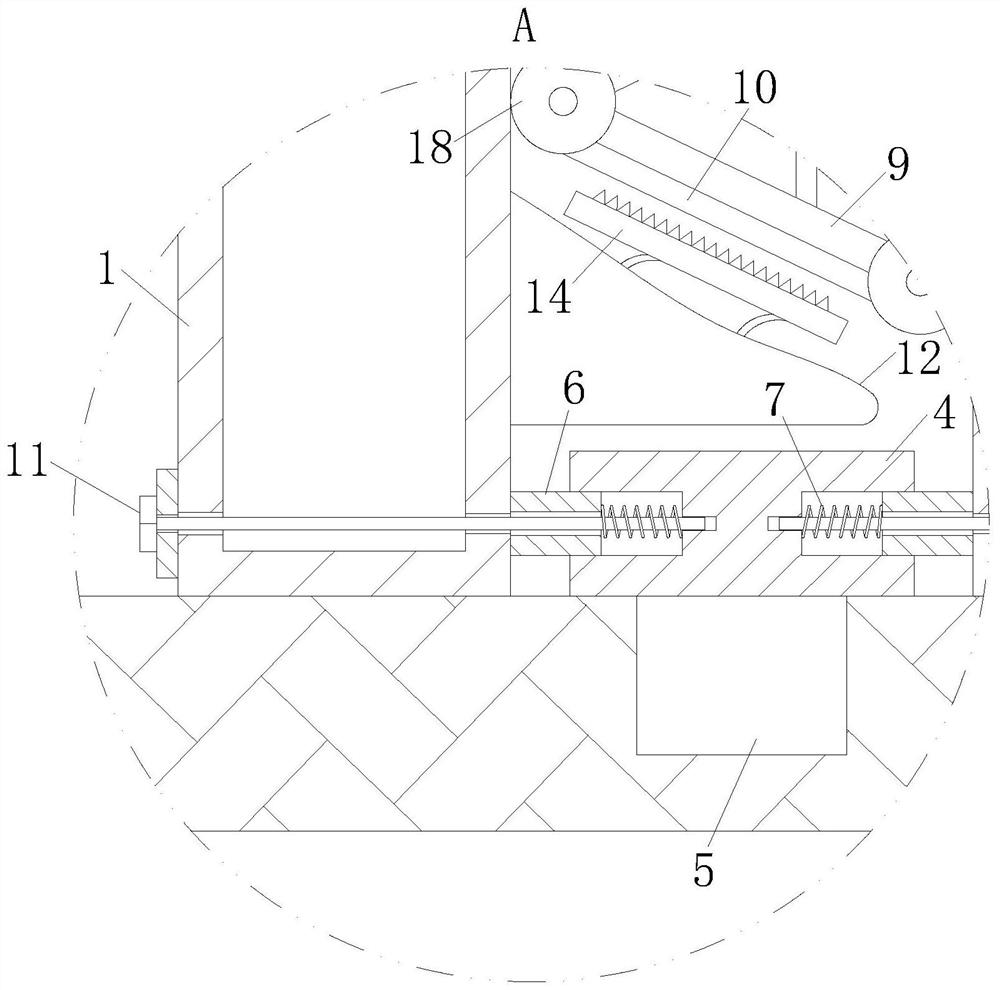

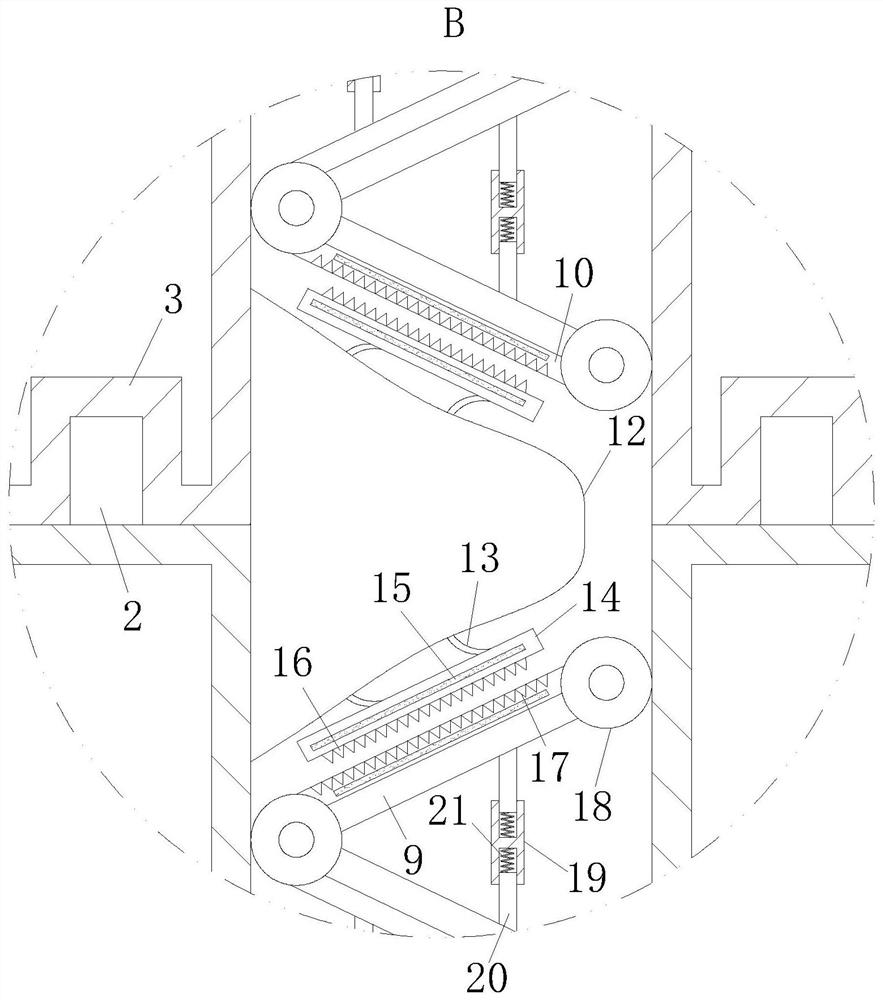

[0028] see Figure 1-Figure 2As shown, the aluminum alloy wall for building decoration described in the embodiment of the present invention includes several wall blocks 1 for splicing the wall; the wall blocks 1 are symmetrically arranged in pairs, and the two symmetrical wall blocks 1 There is a gap between them, the upper and lower ends of the wall block 1 are respectively provided with a clamping block 2 and a clamping cavity 3, and the gaps between the two adjacent wall blocks 1 corresponding to the upper and lower ends of the wall are respectively provided with Fixed block 4, the ends of the two fixed blocks 4 that are far away from each other are respectively connected with embedded blocks 5, and the two ends of the fixed block 4 are respectively slidably connected with sliders 6, and the other ends of the sliders 6 are respectively connected to the corresponding The inner wall of the wall block 1 is fixedly connected, the No. 1 spring 7 is arranged between the sliding b...

Embodiment 2

[0037] Such as Figure 4 As shown in Comparative Example 1, another embodiment of the present invention is: a water-absorbing block 22 is connected to the inner wall of the wall board corresponding to the top side of the sliding column 18, and the water-absorbing block 22 is adsorbed inside Lubricating oil; when the sliding column 18 slides on the inner wall of the wall block 1, the sliding column 18 can extrude the pre-preserved lubricating oil in the water-absorbing block 22, and now the lubricating oil can be stored between the sliding column 18 and the wall block 1, and lubricate the movement path of the subsequent sliding column 18, thereby further reducing the frictional resistance between the sliding column 18 and the wall block 1.

[0038] The inside of the water-absorbing block 22 is provided with a pressure bag 23, and the inner wall of the wall block 1 corresponding to the top of the water-absorbing block 22 is connected with a recovery cavity 24, and the inner bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com