An electrostatic discharge protection semiconductor structure and a method of manufacture

A discharge protection and semiconductor technology, applied in the field of electrostatic discharge protection semiconductor structure, can solve the problems of filament damage, limited usefulness, etc., and achieve the effect of robust electrostatic discharge protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

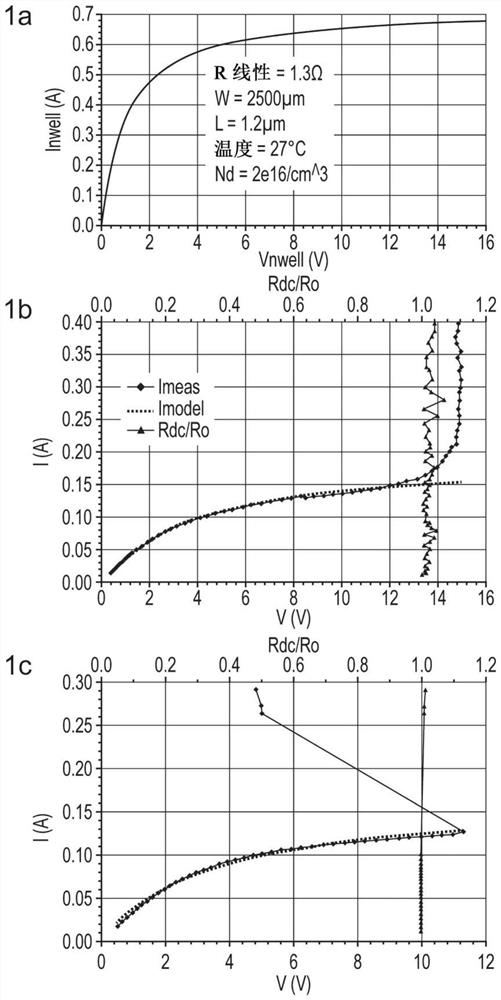

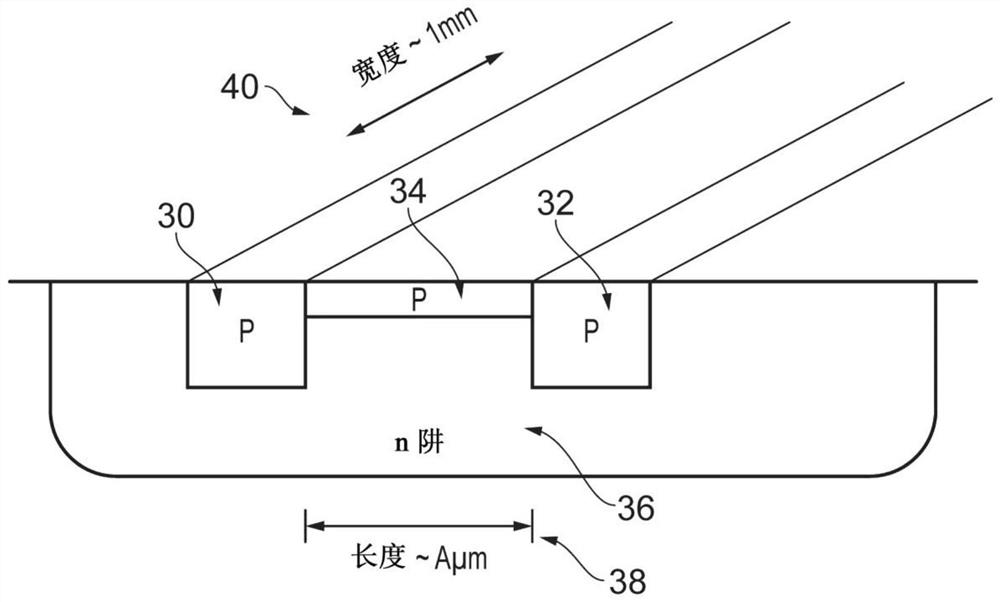

[0046]Embodiments of the present invention relate to velocity-based saturation non-linear resistors having low resistance values for signal transmission current levels and high resistance for ESD current levels. Nonlinear resistors are realized by thin, highly doped diffusions embedded in thicker, similarly highly doped wells with different doping.

[0047] The diffusion resistors according to the invention have no spring back. The resistor will be robust to high current densities since no filamentation will occur. This is achieved with resistors formed from short, thin, highly doped layers embedded in wells with comparable doping levels but with different polarities.

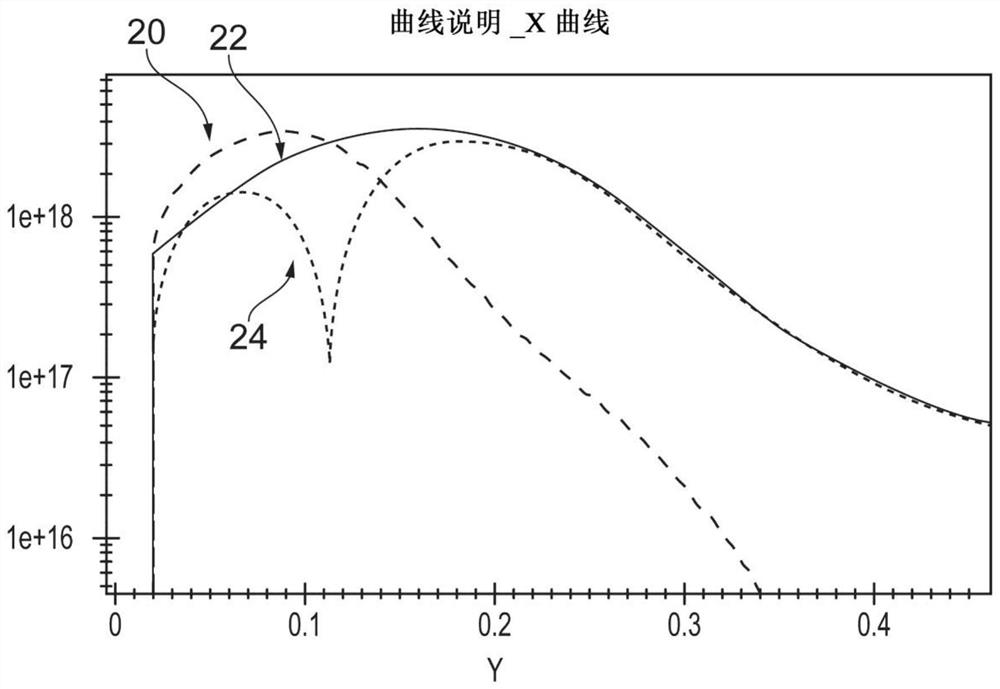

[0048] According to an embodiment of the invention, a suitable implant is used to form a very thin diffusion layer in the range of 0.1 μm with 18 Relatively high doping levels in the range. The corresponding resistive layer is sandwiched between the oxide-covered silicon surface and a similarly highly dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com