High-pressure system cabin with good heat dissipation effect

A technology of high-voltage system and heat dissipation effect, which is applied in the cooling/ventilation of substation/switchgear, electrical components, substation/distribution device casing, etc. Problems such as obstruction of air flow in the cabin can improve the air flow in the cabin, avoid corrosion, and improve the effect of heat dissipation and ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

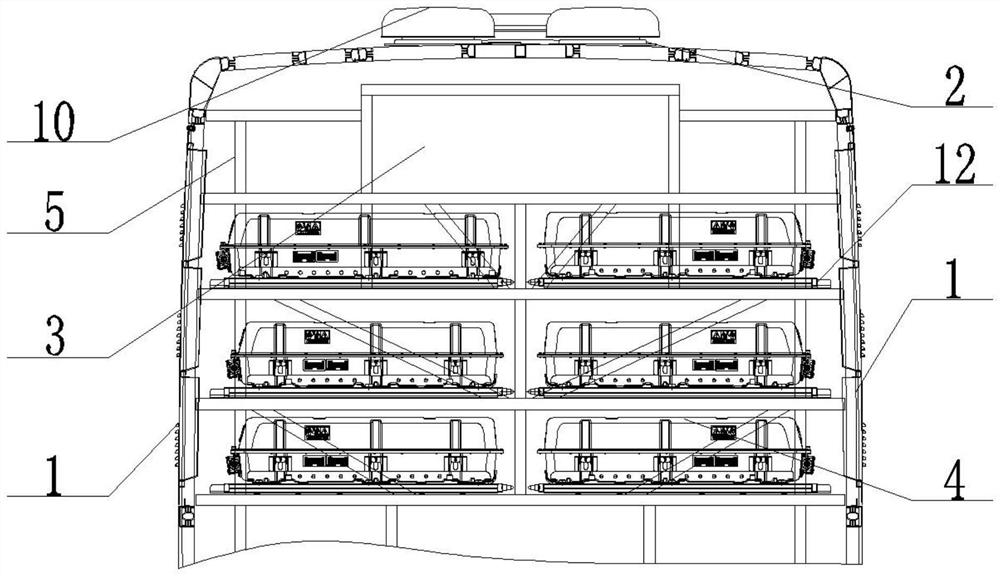

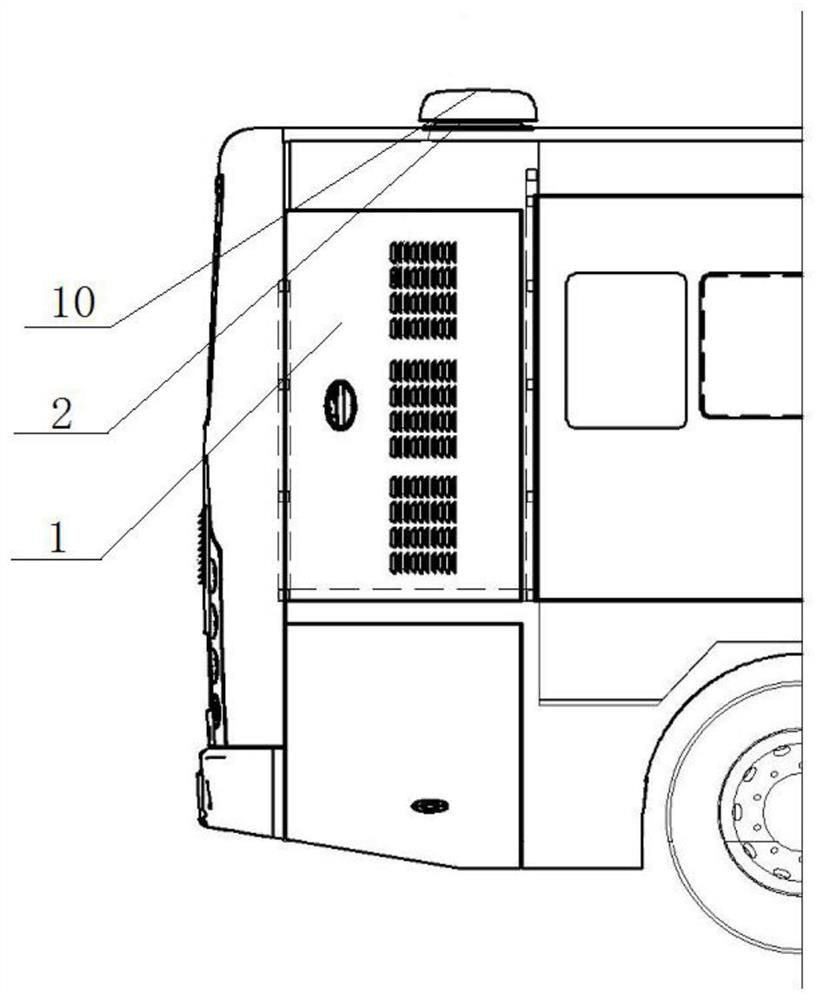

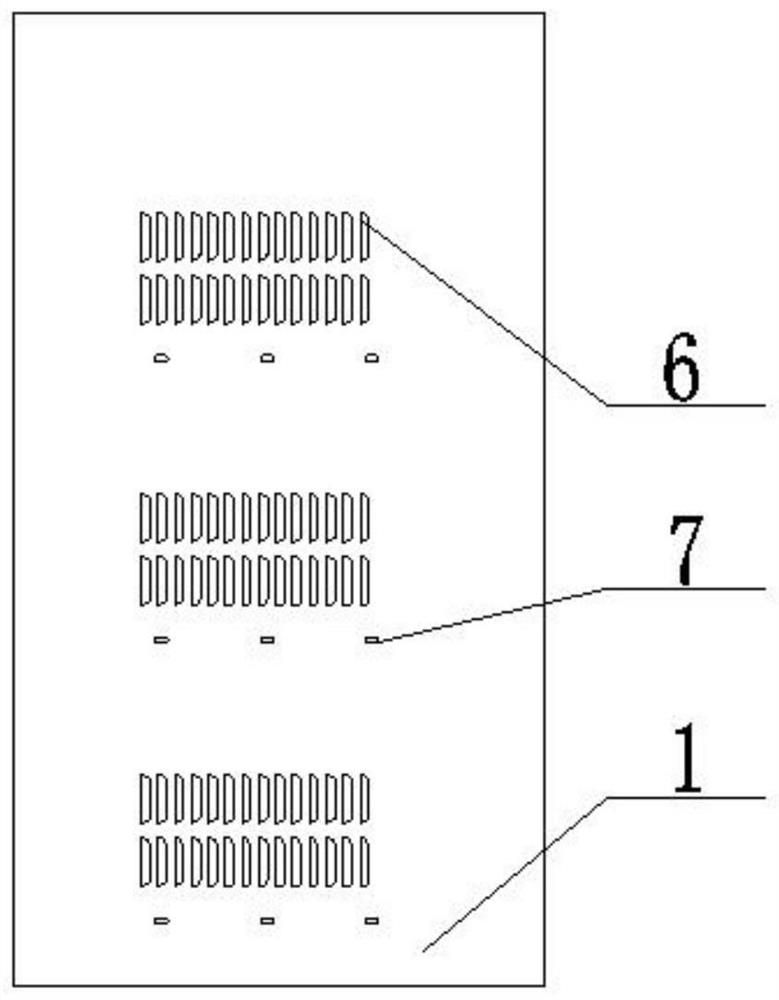

[0025] Embodiment of the present invention: a high-voltage system cabin with good heat dissipation effect, as attached Figure 1-8 As shown, the high-voltage system cabin body 3 is included, and the interior of the high-voltage system cabin body 3 is provided with an electrical component fixing bracket 5, and the electrical component fixing bracket 5 is fixed with a high-voltage electrical component 4 (such as a power battery). A ventilating fan 2 connected to the outside is provided on the top, and a ventilation and waterproof hatch 1 is movably connected to the left and right sides of the high-voltage system cabin body 3, and a plurality of groups of air-induction styles are evenly spaced on the outer wall of the ventilation and waterproof hatch 1. Grille 6, the air intake grille 6 protrudes outwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com