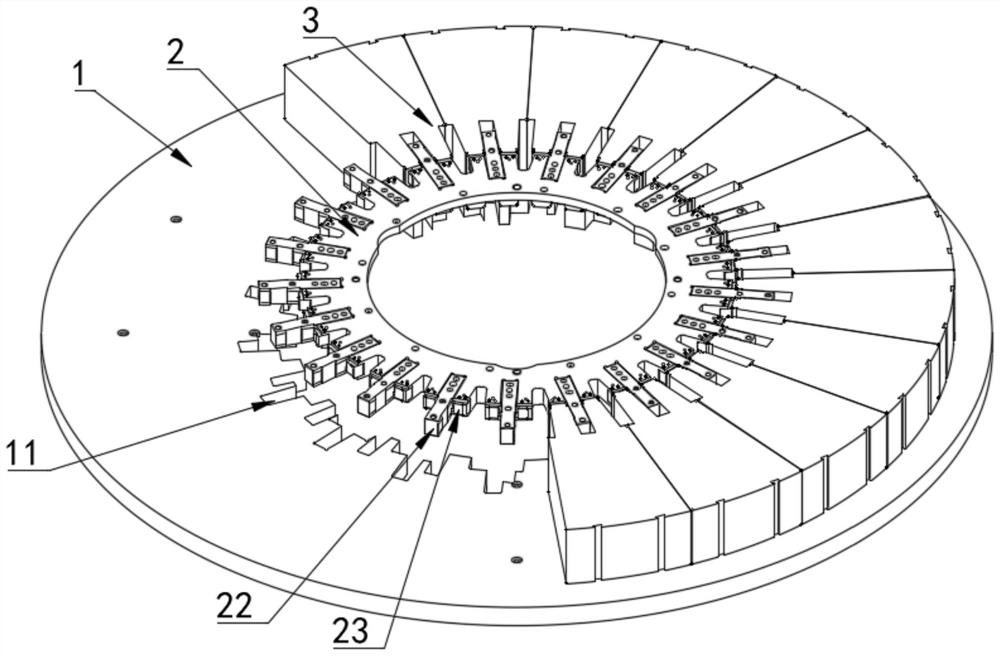

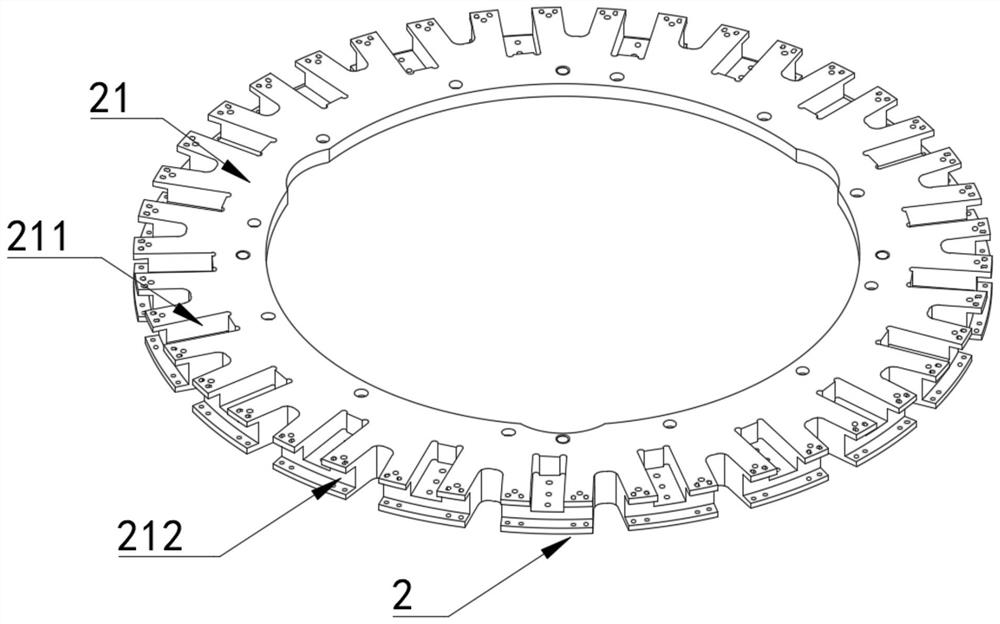

Rotary lamination device and lamination method suitable for fan-shaped lamination motor

A lamination device and fan-shaped punching technology, which are applied in the manufacture of stator/rotor bodies, etc., can solve the problems of reduced stability of the lifting platform, high labor intensity, and difficulty in improving the quality of laminations, so as to improve the quality of laminations and assembly , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

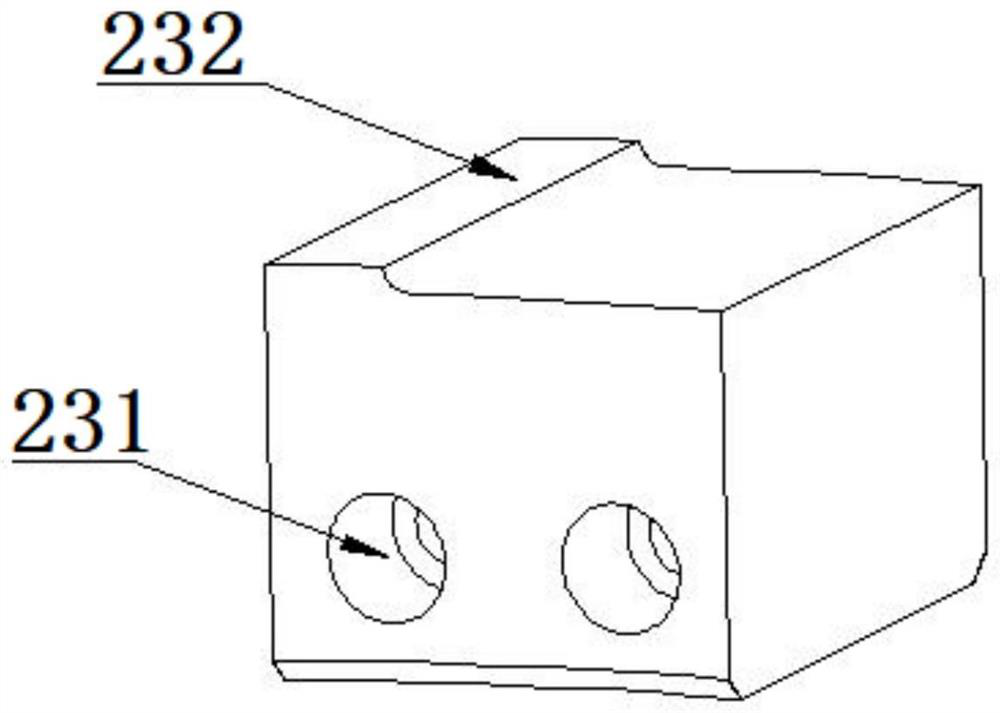

Embodiment Construction

[0042] In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and "fixation" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection , or integrated; it can be directly connected or indirectly connected through an intermediary, it can be the internal communication of two elements or the interaction relationship between two elements. The "first", "second" and similar words mentioned in this application do not indicate any order, quantity or importance, but are only used to distinguish different components. Likewise, words like "a" or "one" do not denote a limitation in number, but indicate that there is at least one. In the implementation of this application, "and / or" describes the association relationship of associated objects, indicating that there may be three types of relationships, for example, A and / or B, which may mean: A exists alone, A and B e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap