Ceramic polyolefin heat-shrinkable material and heat-shrinkable tube prepared therefrom

A technology for ceramizing polyolefin and polyolefin heat, which is applied in the field of polyolefin heat shrinkable materials, can solve the problems of unsuitability for heat shrinkable tubes, cannot expand normally, and different preparation principles, and achieves excellent ceramization performance, good expandability, The effect of reducing the amount of addition

Pending Publication Date: 2022-01-25

NANJING XIYUE IRRADIATION TECH CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although ceramic polyolefin cable materials and ceramic polyolefin heat-shrinkable materials are used in many situations, their preparation principles are different. Ceramic polyolefin heat-shrinkable materials become heat-shrinkable tubes after being extruded, radiated and cross-linked, and then heated and expanded. , the usual ceramic polyolefin cable material is not suitable for the preparation of heat-shrinkable tubes due to the large amount of fillers, high hardness and inability to expand normally.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

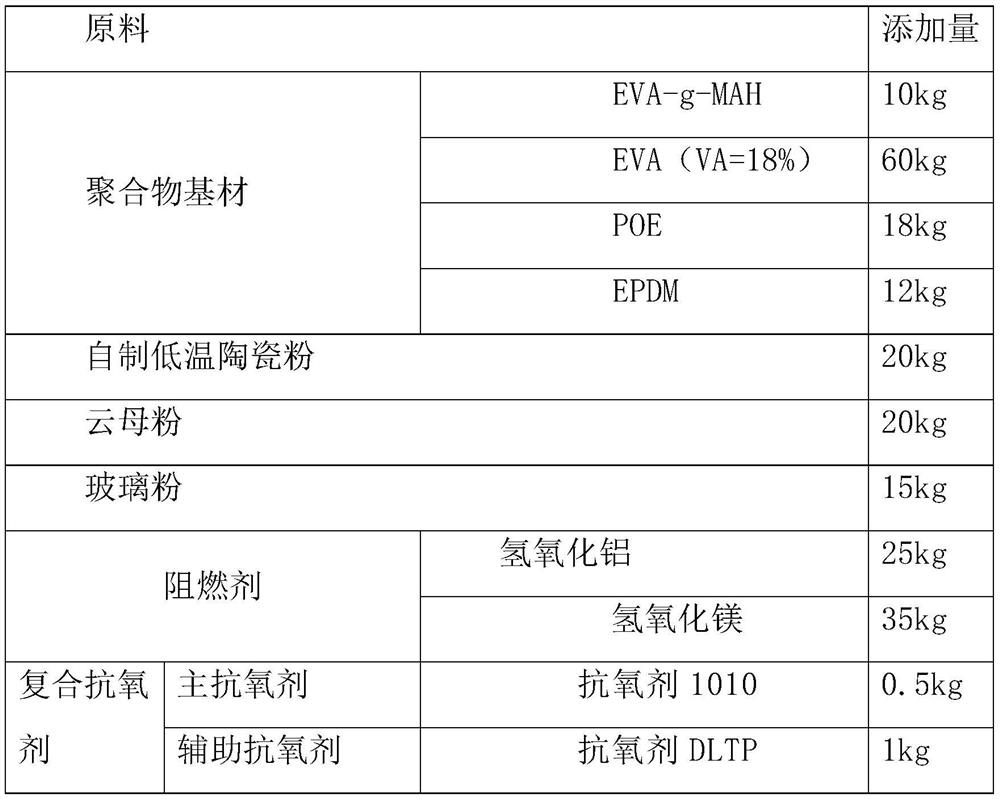

Embodiment 1

[0026]

[0027]

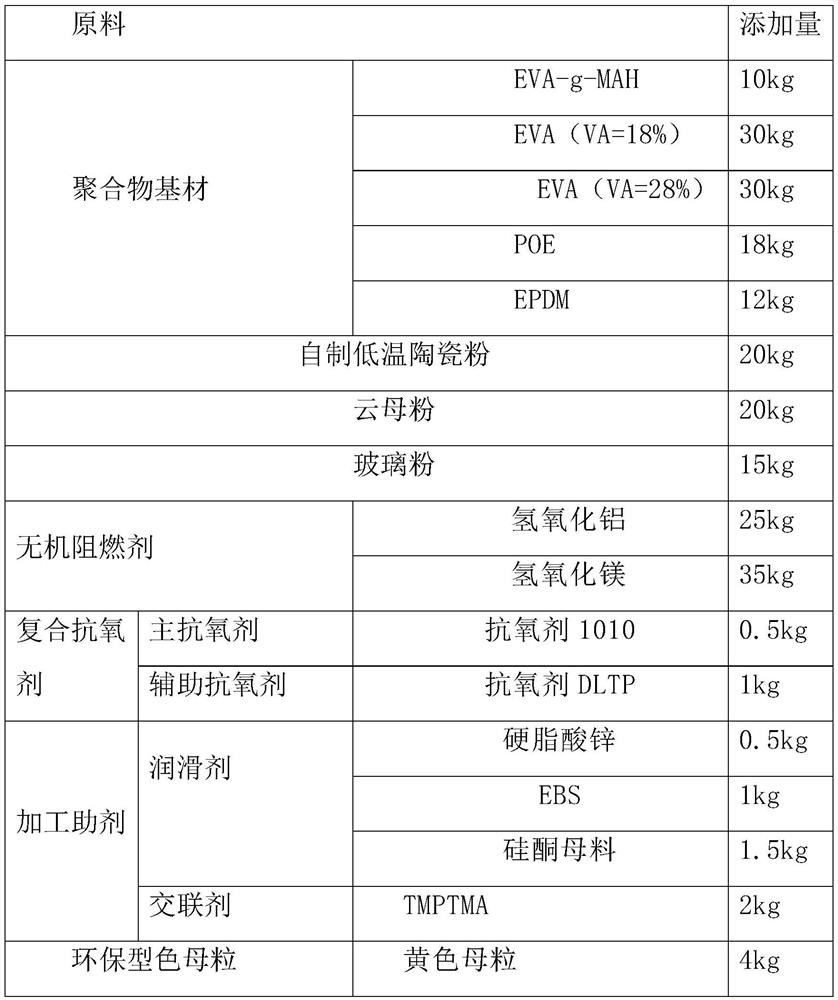

Embodiment 2

[0029]

Embodiment 3

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a ceramic polyolefin material and a heat-shrinkable tube. The shrink tube made of the polyolefin material is soft, is converted into a hard ceramic protection layer through ceramic after catching fire at high temperature, and can be applied to protection occasions of cable joints, power distribution cabinet copper bars and the like with fire-resistant requirements. The ceramic polyolefin material comprises the following raw materials in parts by weight: 100 parts of a polymer base material, 60-80 parts of a flame retardant, 25-40 parts of low-temperature ceramic powder, 15-30 parts of mica powder, 10-25 parts of glass powder, 0.5-2 parts of a composite antioxidant, 1-3 parts of a cross-linking agent, 3-6 parts of a lubricant and 2-6 parts of color master batch, wherein the polymer base material comprises 20-40 parts of a thermoplastic elastomer, and the low-temperature ceramic powder is composed of silicon oxide and aluminum oxide. The ceramic heat-shrinkable material and the heat-shrinkable tube provided by the invention have the advantages of excellent ceramic performance, good expansibility and good processability.

Description

technical field [0001] The invention belongs to the field of polyolefin heat-shrinkable materials, and in particular relates to a ceramicized polyolefin heat-shrinkable material and a heat-shrinkable tube made therefrom. Background technique [0002] With the rapid economic development and the continuous improvement of living standards, human beings have an all-round increase in safety awareness, and the safety of electricity use is becoming increasingly strict. Since the fire-resistant cable can guarantee the emergency facilities and equipment to continue to run for a certain period of time within a reasonable period of time in the burning state, the firefighters won precious time for the escape of the trapped people in the fire. In this case, ceramic polymer composite materials such as silicone rubber, polyolefin and other fireproof cables came into being. [0003] Fire-resistant cables made of ceramic polymer composite materials have been successfully applied to various ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/08C08L51/06C08L23/16C08K3/34C08K3/40C08K3/22C08K5/134

CPCC08L23/0853C08L23/0869C08K2003/2227C08K2003/2224C08L2203/18C08L2205/025C08L23/0815C08L51/06C08L23/16C08K3/34C08K3/40C08K3/22C08K5/1345

Inventor 胡钧张聪

Owner NANJING XIYUE IRRADIATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com