Preparation process of milk tea beverage

A beverage and milk tea technology, which is applied in the field of preparation of milk tea beverages, can solve the problems of incomplete proportioning of chemical additives, damage to tea fragrance, and insufficient freshness of the product, and achieve excellent thickening, smooth taste, and uniform milk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

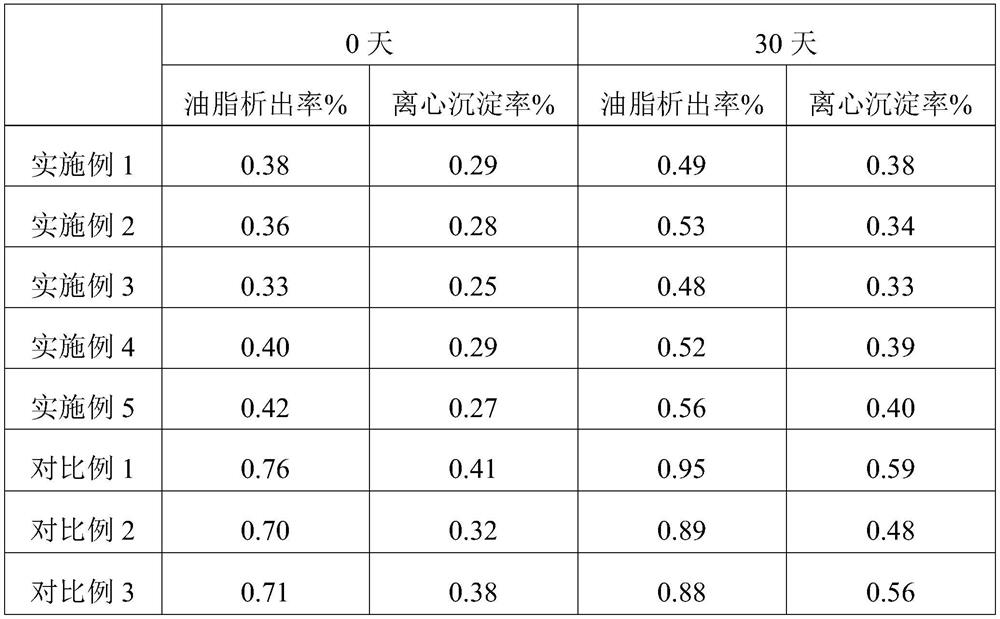

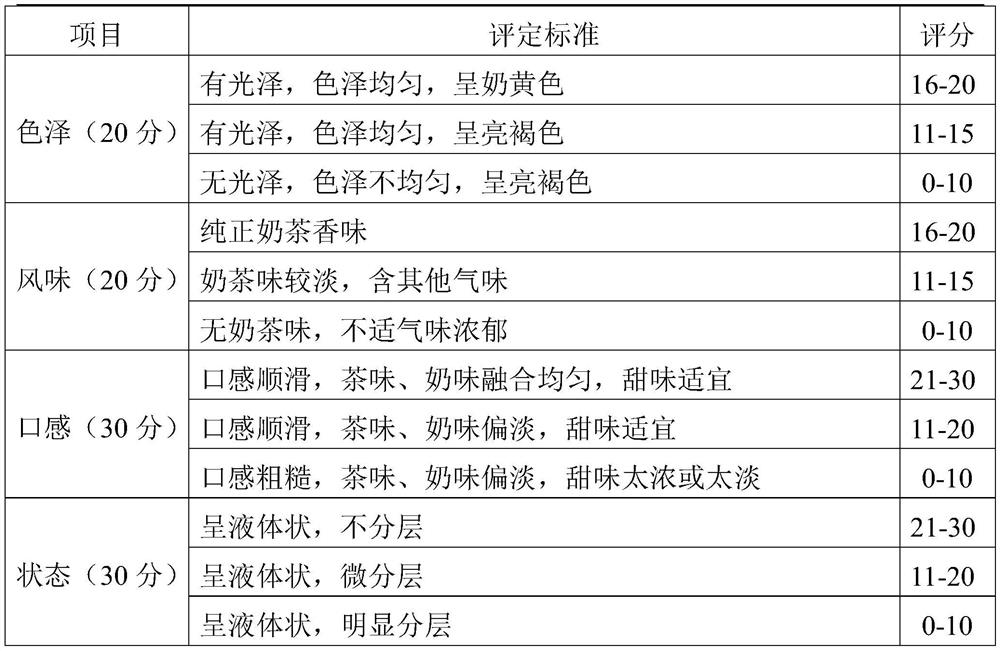

Examples

Embodiment 1

[0020] A kind of milk tea beverage: including the following raw materials in parts by weight: 50 parts of milk powder, 10 parts of coconut oil, 40 parts of collagen powder, 11 parts of non-dairy creamer, 55 parts of instant tea powder, 30 parts of tea liquid, 5 parts of stabilizer, citric acid 3 parts of sodium, 3 parts of sodium tripolyphosphate, 1 part of sodium D-isoascorbate, 2 parts of baking soda, 2 parts of white granulated sugar, and the stabilizer is vitexin rhamnoside with a weight ratio of 4:10:6, Disodium dihydrogen pyrophosphate, flax lignans.

Embodiment 2

[0022] A milk tea beverage: comprising the following raw materials in parts by weight: 120 parts of milk powder, 15 parts of coconut oil, 80 parts of collagen powder, 30 parts of non-dairy creamer, 100 parts of instant tea powder, 60 parts of tea liquid, 12 parts of stabilizer, citric acid 10 parts of sodium, 8 parts of sodium tripolyphosphate, 3 parts of sodium D-isoascorbate, 12 parts of baking soda, 5 parts of white granulated sugar, and the stabilizer is vitexin rhamnoside with a weight ratio of 2:8:1, Disodium dihydrogen pyrophosphate, flax lignans.

Embodiment 3

[0024] A milk tea beverage, comprising the following raw materials in parts by weight: 80 parts of milk powder, 12 parts of coconut oil, 60 parts of collagen powder, 22 parts of non-dairy creamer, 80 parts of instant tea powder, 50 parts of tea liquid, 8 parts of stabilizer, citric acid 7 parts of sodium, 6 parts of sodium tripolyphosphate, 2 parts of sodium D-isoascorbate, 7 parts of baking soda, 3 parts of white granulated sugar, and the stabilizer is vitexin rhamnoside with a weight ratio of 3:9:4, Disodium dihydrogen pyrophosphate, flax lignans.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com