Casting cooling device for stainless steel pipe cast steel machining

A cooling device and stainless steel technology, which is applied in the field of casting cooling devices for stainless steel pipe casting steel processing, can solve the problems of slow cooling effect, prone to oxidation, thermal deformation of stainless steel pipe fittings, and achieve the effect of convenient rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

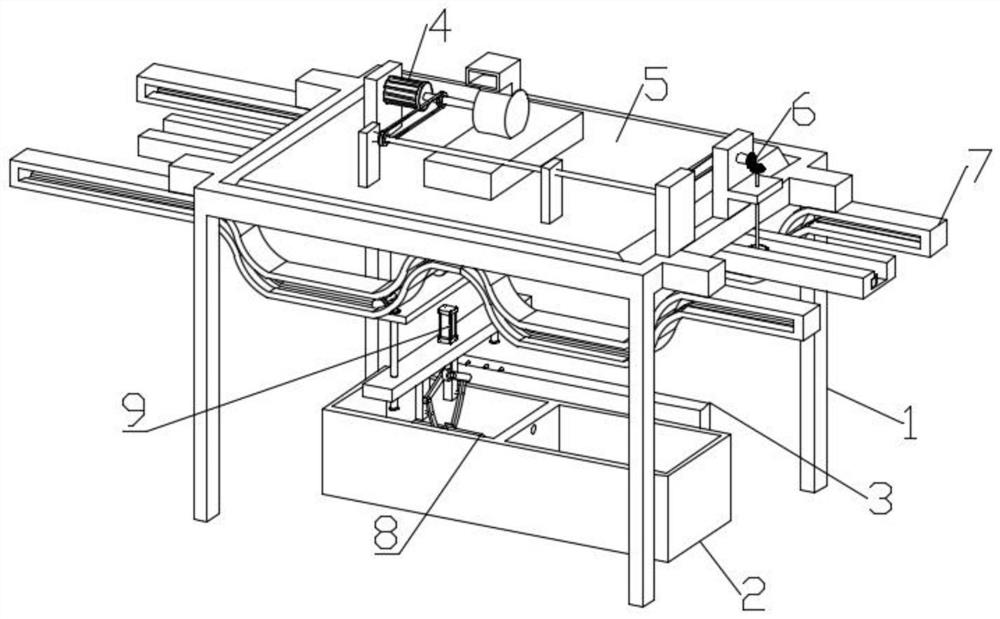

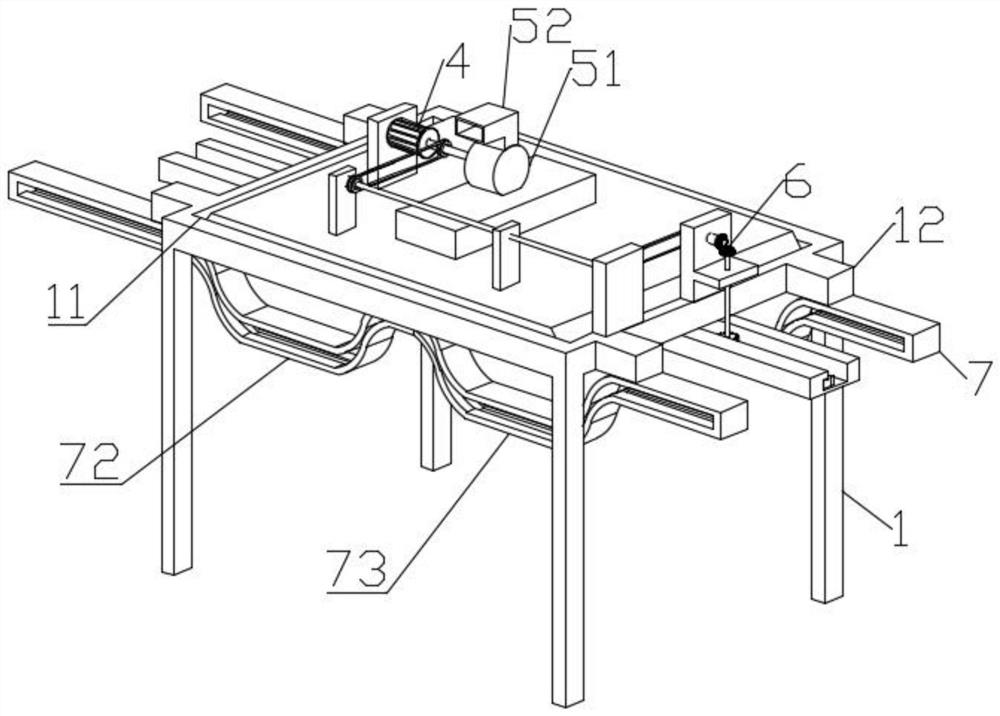

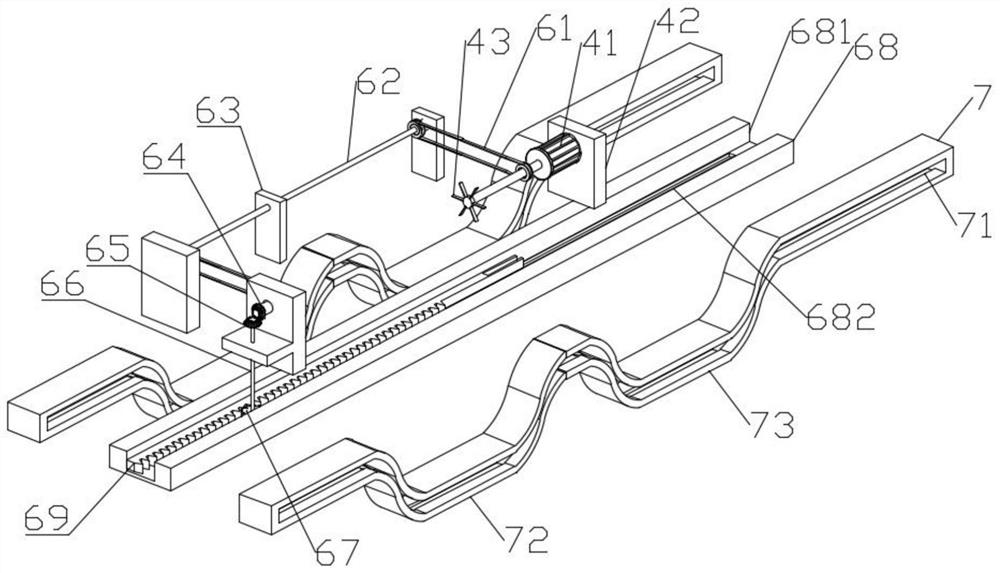

[0024] Example: such as Figure 1 to Figure 6 As shown, the present invention provides a casting cooling device for processing stainless steel pipe fittings, which includes a bottom frame 1, an installation groove 11 is opened on the upper surface of the bottom frame 1, and an air collecting cover 5 is fixedly installed in the installation groove 11 , the gas collecting hood 5 is fixedly installed on the upper end of the bottom frame 1 for collecting steam, the two ends of the bottom frame 1 are symmetrically fixed with a connecting seat 12, and the bottom end of the connecting seat 12 is fixed with a guide plate 7, and the guide plate 7 is fixed Installed and used for guiding use, the upper surface of the air collecting hood 5 is fixedly installed with a power device 4, so that the gas collecting hood 5 can quickly collect air through the power device 4, and the air cooling effect can be realized through the power device 4. The power device 4 is rotationally connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com