Metal plate welding device for machining and welding method

A welding device and mechanical processing technology, applied in the field of metal plate welding, can solve the problems of changing the position of the metal plate, affecting the welding result of the metal plate, affecting the welding quality, etc., and achieving the effect of ensuring the welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

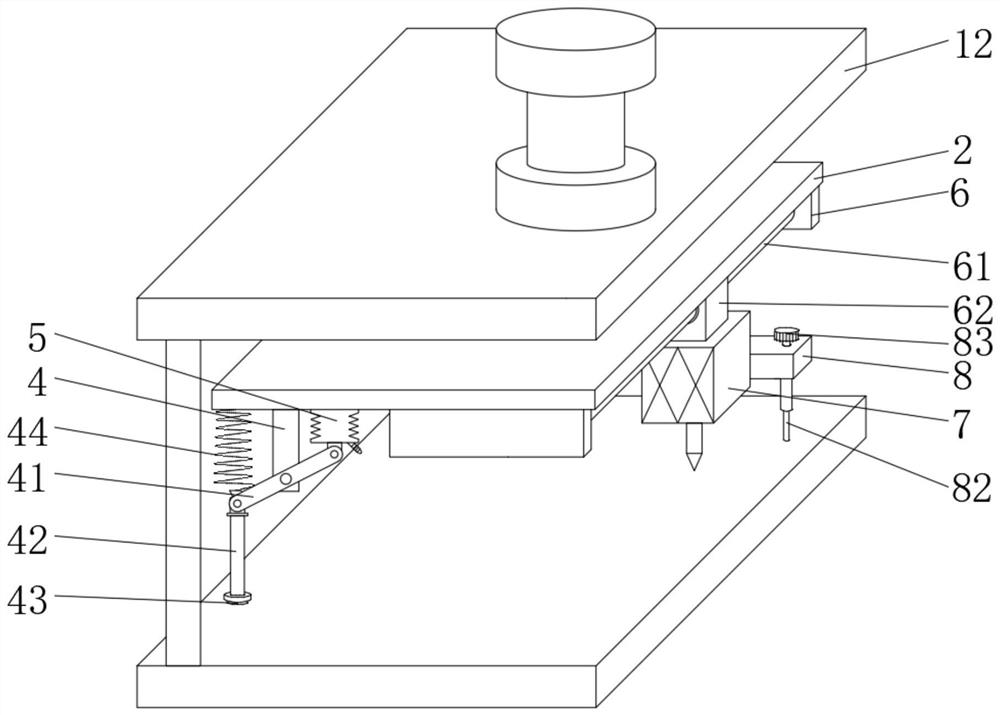

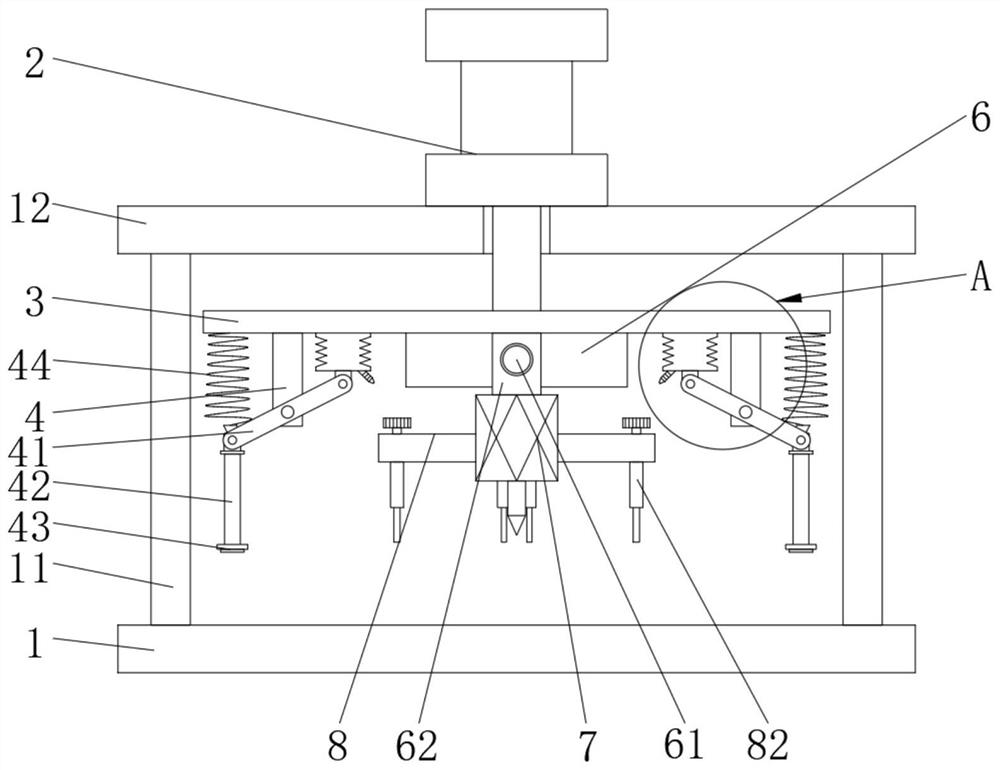

[0031] see Figure 1-2 and Figure 4-5 , the present embodiment provides a metal plate welding device for mechanical processing, comprising a base plate 1, a support column 11 fixedly installed on the upper surface of the base plate 1, and a top plate 12 fixedly installed on the upper end of the support column 11, the lower surface of the installation plate 3 is fixed Front and rear symmetrical risers 6 are installed, threaded rods 61 are installed in rotation between the two risers 6, a motor driving the threaded rods 61 is installed on one of the risers 6, and a moving block 62 is screwed on the threaded rods 61, The lower end of the moving block 62 is fixedly connected with the welding machine 7, and the motor can drive the threaded rod 61 to rotate. When the threaded rod 61 rotates, the moving block 62 can be driven to move along its axial direction, so that the welding machine 7 can be moved along the gap of the metal plate. Move to weld along the gap in the sheet metal....

Embodiment 2

[0039] refer to Figure 1-3 , a further improvement made on the basis of Example 1:

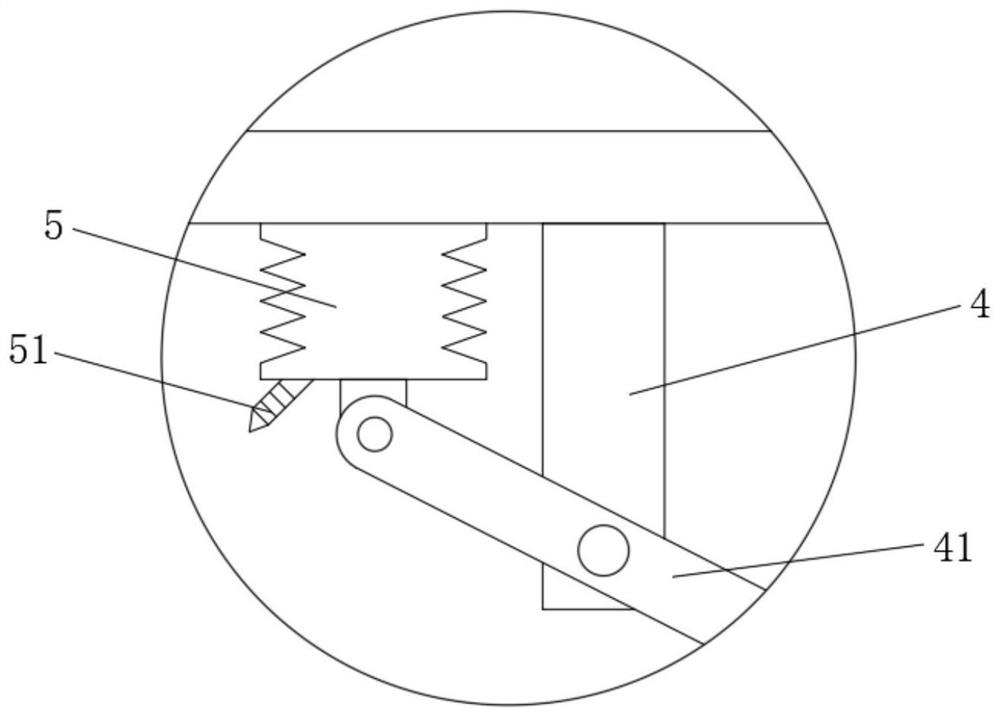

[0040] The upper surface of the top plate 12 is fixedly equipped with the cylinder 2, the output end of the cylinder 2 runs through the top plate 12 and is fixedly connected with the installation plate 3, and the four corners of the lower surface of the installation plate 3 are fixedly installed with the rotating bracket 4, and the lower end of the rotating bracket 4 is rotated and installed. There is a rotating rod 41, one end of the rotating rod 41 is rotatably mounted with a lower pressing rod 42, and the lower end of the lower pressing rod 42 is fixedly connected with a pressing plate 43.

[0041] When the mounting plate 3 moved downwards, the pressing plate 43 at the lower end of the lower pressing rod 42 was in contact with the upper surface of the metal plate, and as the mounting plate 3 continued to move downward, the upper end of the lower pressing rod 42 would push the rotating rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com