Full-automatic welding manipulator for steel pipe furniture and welding method of full-automatic welding manipulator

A fully automatic welding and manipulator technology, applied in the field of steel pipe welding, can solve the problems of easy welding mistakes, waste, damage of raw materials, etc., and achieve the effect of increasing the welding range, fast and stable welding, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

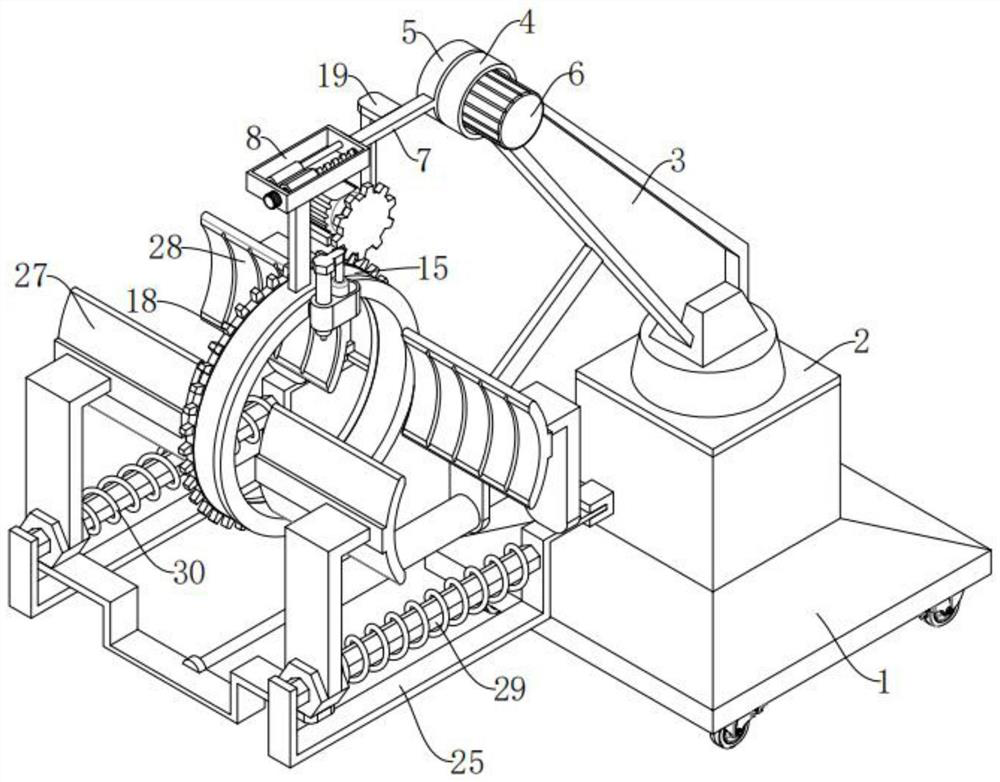

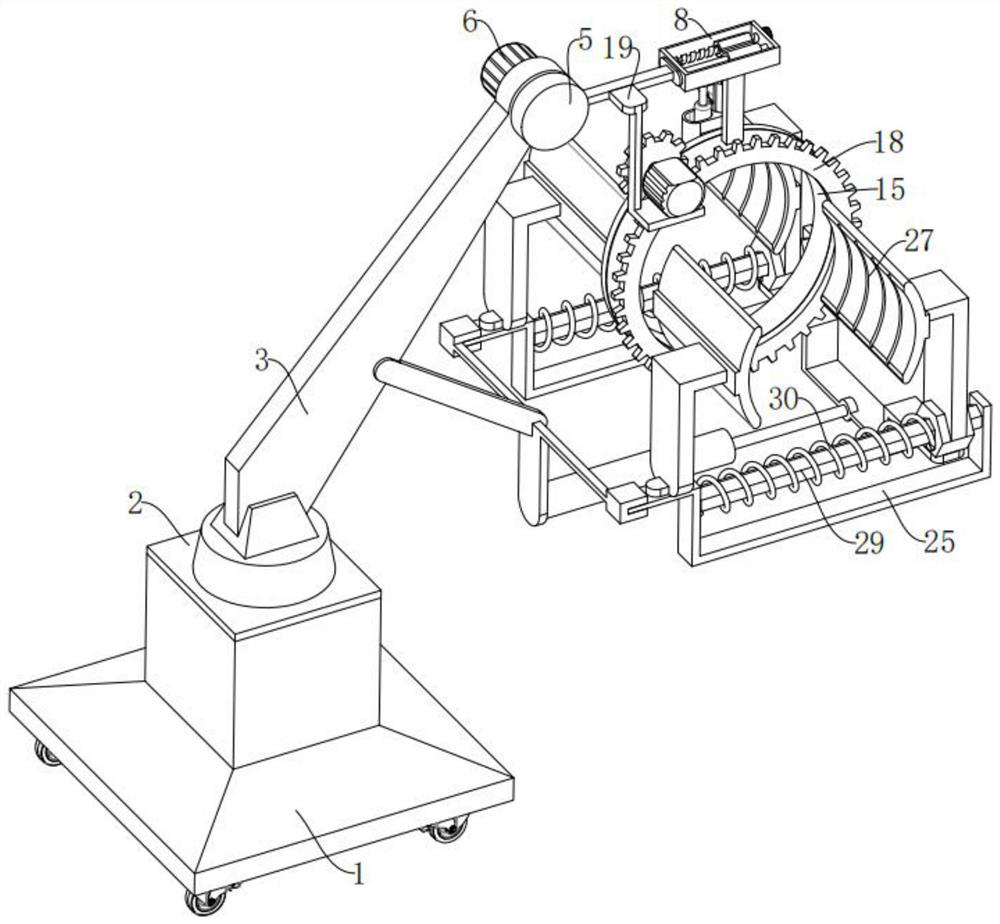

[0038] see Figure 1-6 , a steel pipe furniture automatic welding manipulator and its welding method, the center of gravity base 1;

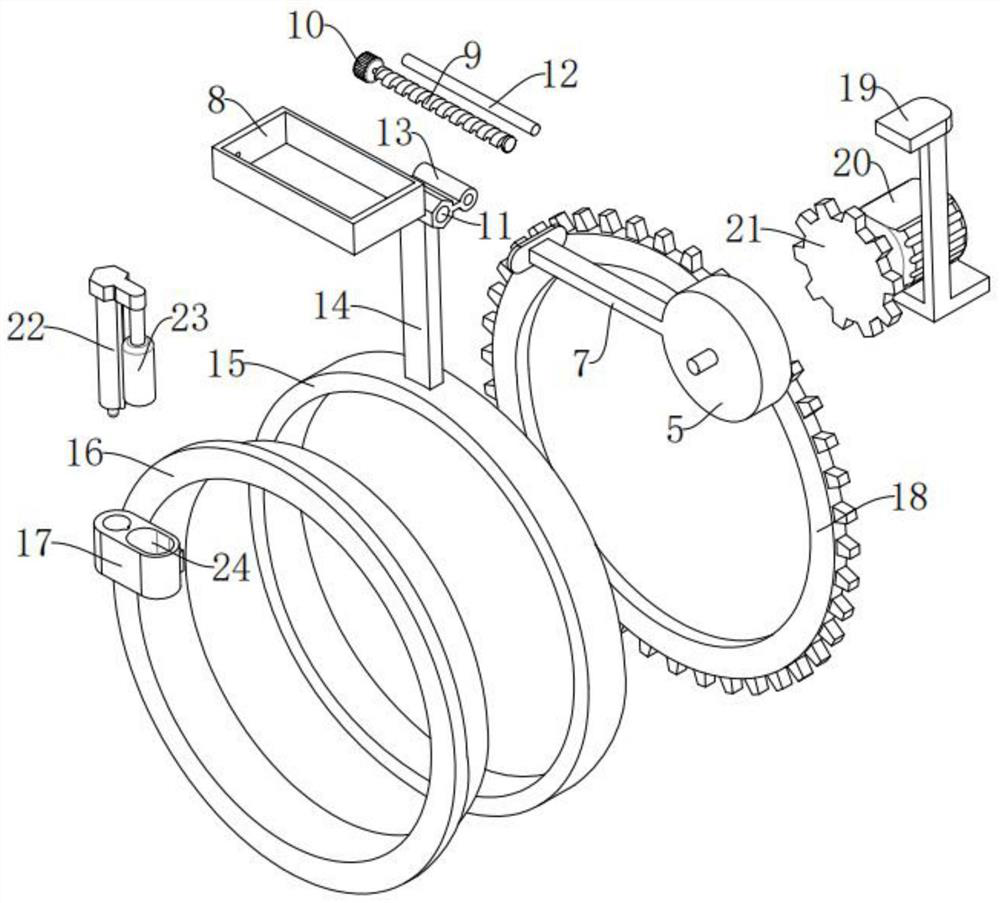

[0039]The supporting assembly includes a mounting plate 2, a supporting arm 3, an extension arm 7 and a mounting frame 8, the mounting plate 2 is fixedly connected to the upper end of the center of gravity base 1, the supporting arm 3 is fixedly connected to the upper end of the mounting plate 2, one end of the extending arm 7 and An adjustment component is arranged between the support arms 3, and the adjustment component is used to adjust the position of the installation frame 8, and the installation frame 8 is fixedly connected to the other end of the extension arm 7;

[0040] The rotating assembly includes a static installation ring 15, a dynamic installation ring 16 and a large gear 18. The static installation ring 15 is arranged on the lower side of the installation frame 8, and the dynamic installation ring 16 is rotatably connected in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com