Wire core penetrating equipment for manufacturing automobile inhaul cable

A wire core and equipment technology, which is applied in the field of wire core penetration equipment for automobile cable manufacturing, can solve the problems of time-consuming, low work efficiency, wire core splitting, etc., so as to reduce labor intensity and avoid wire core splitting. , the effect of preventing sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

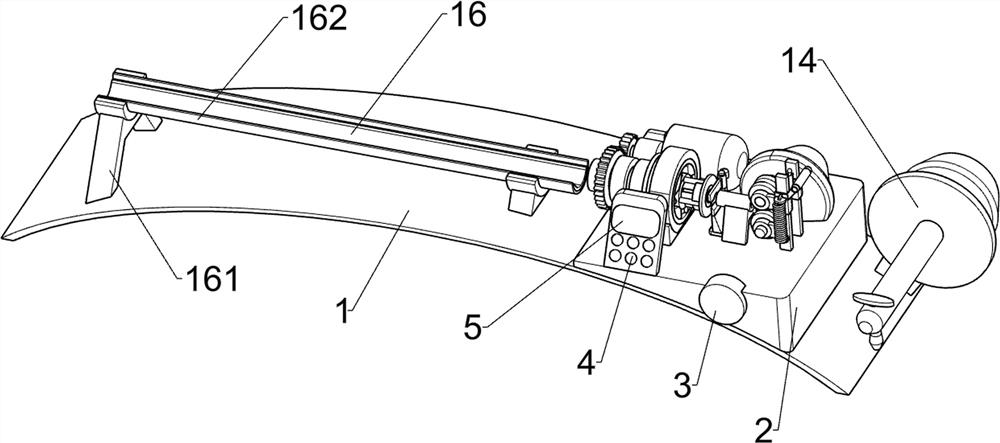

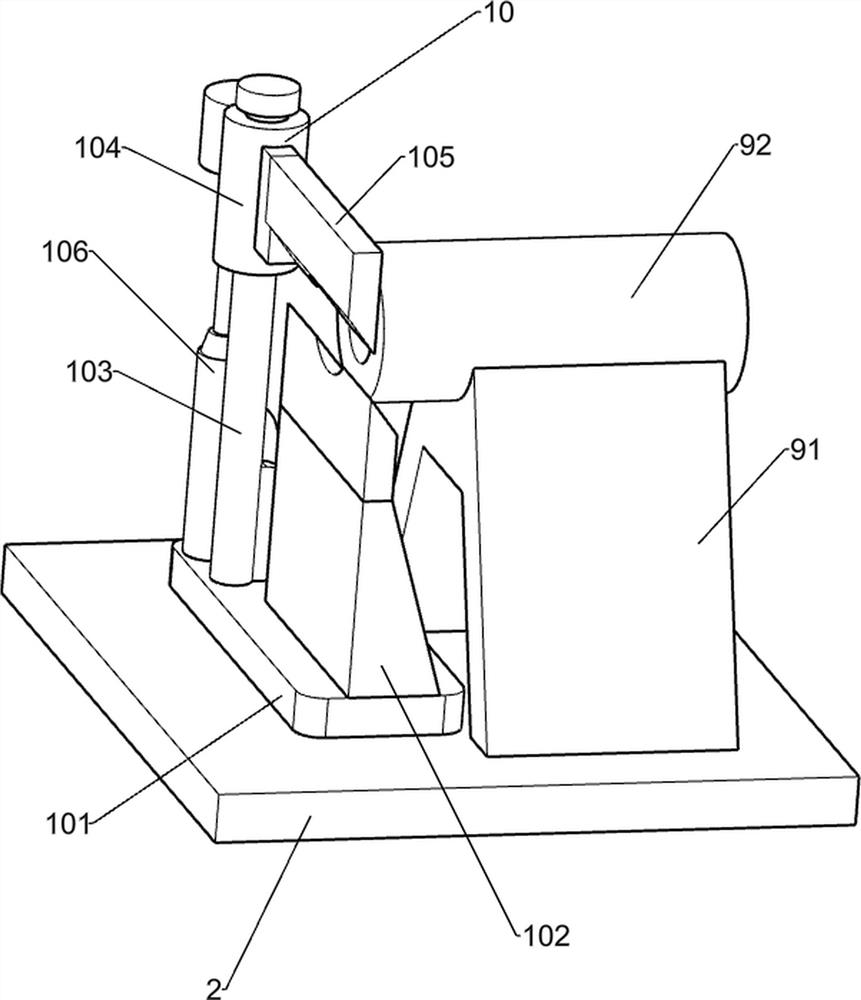

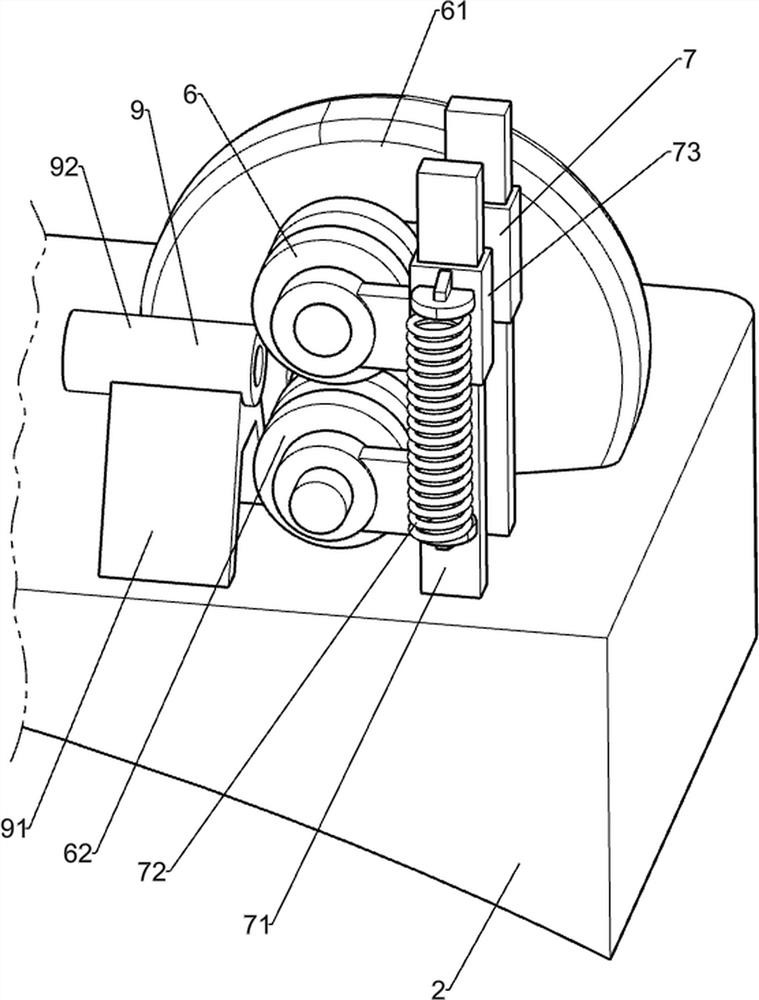

[0036] A wire core threading device for automobile cable manufacturing, such as Figure 1-14As shown, it includes a base 1, a mounting plate 2, a control panel 4, an LCD display 5, a pressure roller 6, a first reduction motor 61, a friction roller 62, a pressing mechanism 7 and an alignment mechanism 9, and the right side of the top of the base 1 A mounting plate 2 is provided, and a control panel 4 is provided on the left front side of the top of the mounting plate 2. The control panel 4 is provided with setting keys, switching keys and confirmation keys. A switching power supply, a power module and a control module are installed. The switching power supply supplies power to the entire device. The output end of the switching power supply is electrically connected to the power module. connection, the control module is connected with a DS1302 clock circuit and a 24C02 circuit, and the setting key, switch key and confirmation key are all electrically connected with the control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com