High-strength isolating membrane for tire production

A high-strength, isolation film technology, applied in the field of tire production, can solve the problems of easy deformation and folds of the isolation film, and cannot be used for a second time, and achieves the effect of avoiding pulling and deformation, improving the reinforcement effect, and improving the strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

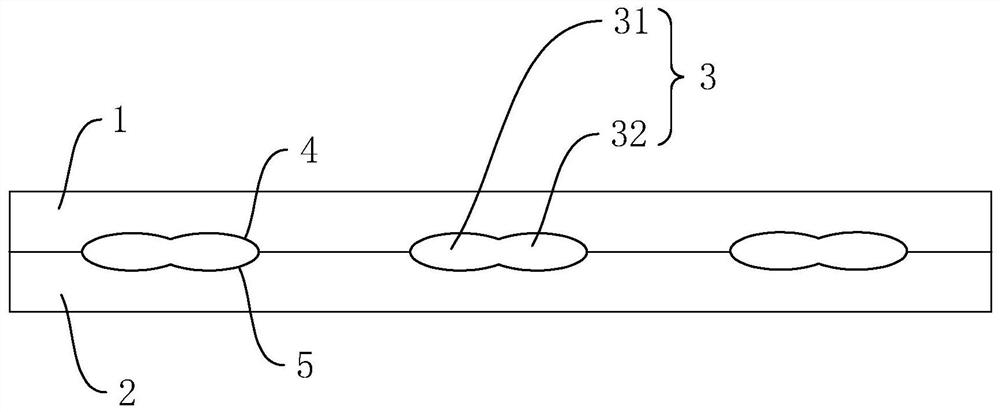

[0031] refer to Figure 1-2 , is a high-strength isolation film for tire production disclosed by the present invention, comprising a first plastic layer 1 and a second plastic layer 2 with the same shape and size. Both the first plastic layer 1 and the second plastic layer 2 are made of polyethylene material, the first plastic layer 1 and the second plastic layer 2 are arranged in alignment, the first plastic layer 1 is located above the second plastic layer 2, and the first plastic layer 1 is attached to the second plastic layer 2.

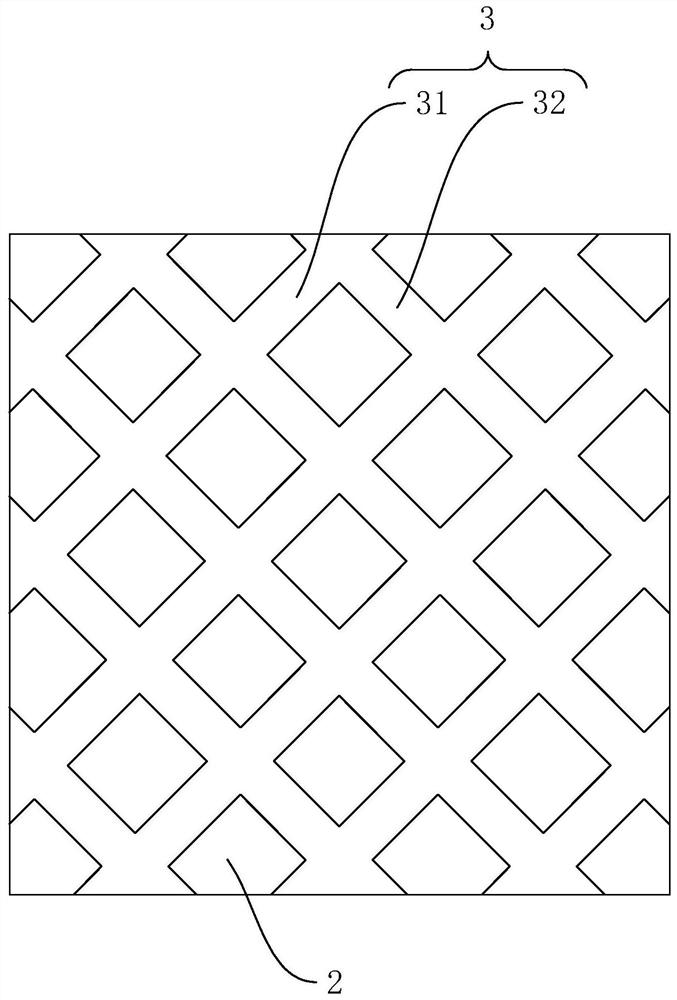

[0032] A reinforcing net 3 is arranged between the first plastic layer 1 and the second plastic layer 2 , and the reinforcing net 3 includes a plurality of first reinforcing strips 31 and a plurality of second reinforcing strips 32 . Both the first reinforcing strip 31 and the second reinforcing strip 32 are made of thermoplastic polyurethane elastomer material, which has excellent high tension, high tensile force, toughness and aging resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com